A preparation method of c/c-sic composite material containing carbon-rich boron nitride interface phase

A carbon boron nitride boundary and composite material technology, applied in the field of fiber reinforced ceramic matrix composite material preparation, can solve the problems of poor BN interface uniformity, poor wettability of liquid silicon, etc., and achieves improved bonding, improved mechanical properties, improved efficiency and The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

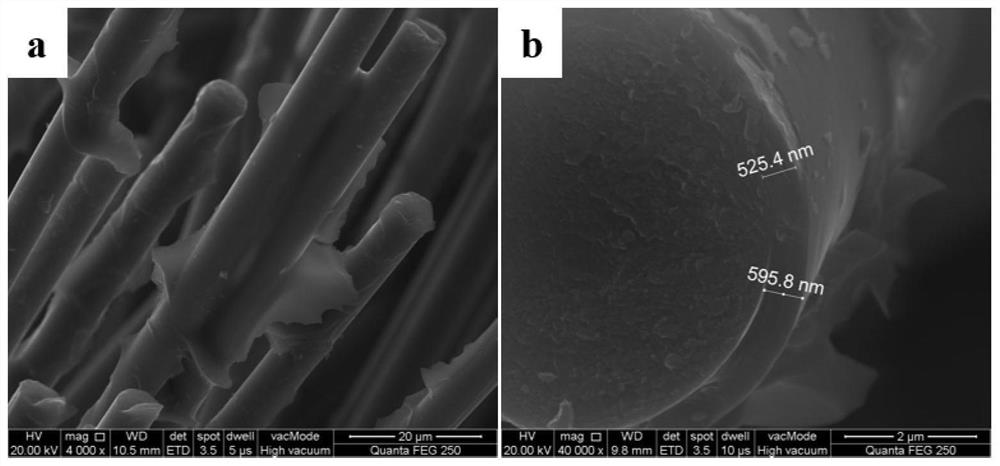

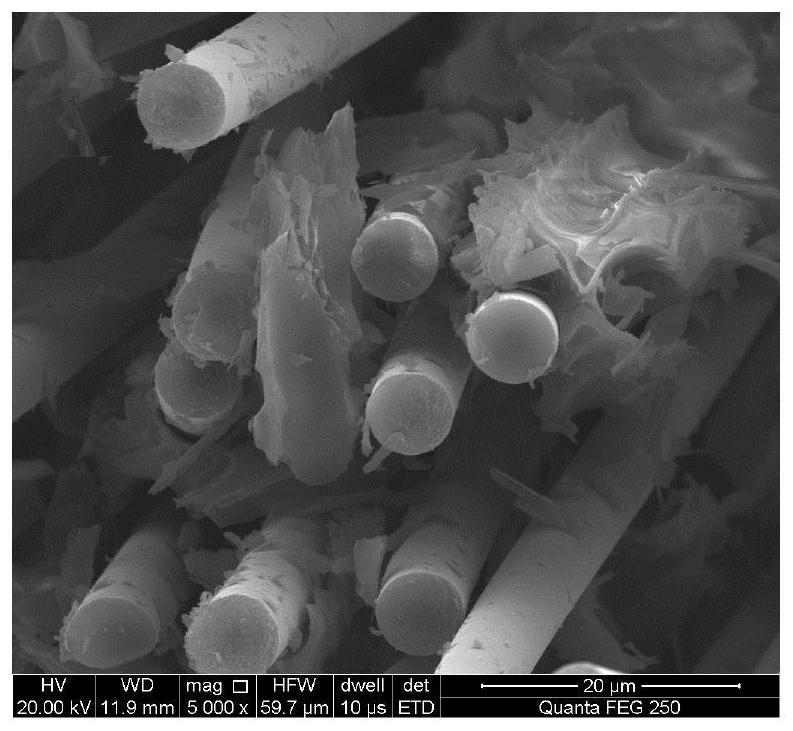

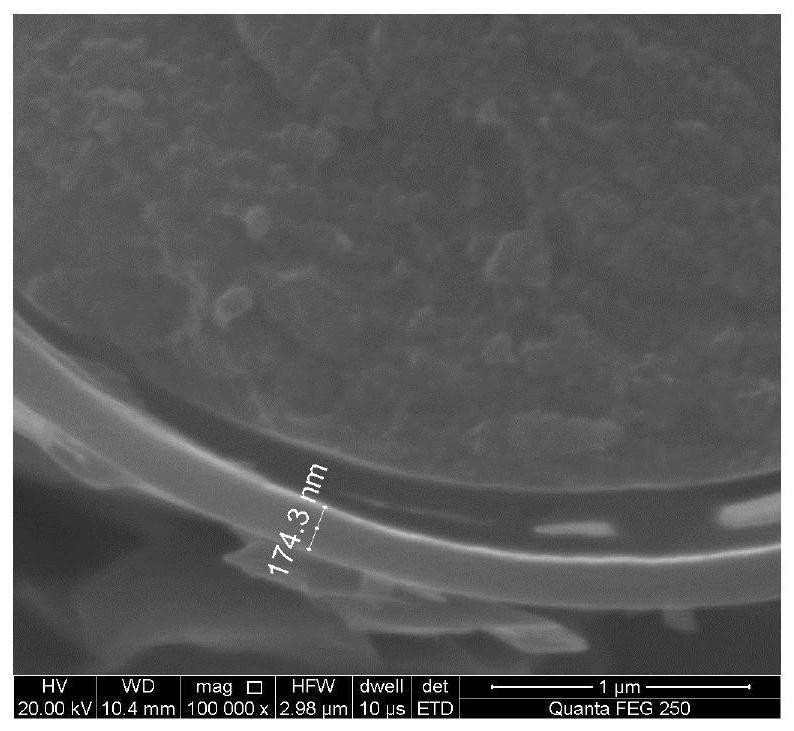

Image

Examples

Embodiment 1

[0036] Preparation of carbon-rich boron nitride interfacial phase

[0037] 1) Dissolve 40 g of boric acid and 120 g of urea in a mixed solvent of 400 ml of ethanol and water (V B: V water = 1:1), heat in a water bath at 80°C, and stir for 30 minutes to dissolve to obtain precursor solution A; in precursor solution A Add 10g of monomer acrylamide (AM) and 0.4g of cross-linking agent N,N'-methylenebisacrylamide (MBAM), stir to dissolve, cool down to 40°C and add 1.7856g of initiator ammonium persulfate (APS), Stir for 10min to initiate polymerization reaction to form sol solution B;

[0038] 2) Set the density to 0.55g / cm 3The 2.5D needle-punched integral felt was degummed at 800°C in an inert atmosphere in a vacuum carbon tube furnace, then immersed in sol solution B at 40°C for 20 minutes, taken out and dried at 80°C for 40 minutes, and repeated this treatment 4 times. After drying, the carbon felt is heat-treated under normal pressure in a nitrogen atmosphere to obtain a un...

Embodiment 2

[0042] Preparation of carbon-rich boron nitride interfacial phase

[0043] 1) Dissolve 40 g of boric acid and 120 g of urea in a mixed solvent of 400 ml of ethanol and water (V B: V water = 1:1), heat in a water bath at 80°C, and stir for 30 minutes to dissolve to obtain precursor solution A; in precursor solution A Add 15g of monomer acrylamide (AM) and 0.6g of cross-linking agent N,N'-methylenebisacrylamide (MBAM), stir to dissolve, cool down to 40°C and add 1.7856g of initiator ammonium persulfate (APS), Stir for 10min to initiate polymerization reaction to form sol solution B;

[0044] 2) The 2.5D needle-punched integral felt with a density of 0.55g / cm3 is degummed at 800°C under an inert atmosphere in a vacuum carbon tube furnace, then immersed in sol solution B at 40°C for 20 minutes, taken out and dried at 80°C for 40 minutes, Repeat this treatment 4 times, and heat-treat the carbon felt after repeated impregnation and drying treatment in a nitrogen atmosphere at norma...

Embodiment 3

[0046] Preparation of carbon-rich boron nitride interfacial phase

[0047] 1) Dissolve 40 g of boric acid and 120 g of urea in a mixed solvent of 400 ml of ethanol and water (V B: V water = 1:1), heat in a water bath at 80°C, and stir for 30 minutes to dissolve to obtain precursor solution A; in precursor solution A Add 5g of monomer acrylamide (AM) and 0.2g of cross-linking agent N,N'-methylenebisacrylamide (MBAM), stir to dissolve, cool down to 40°C and add 1.7856g of initiator ammonium persulfate (APS), Stir for 10min to initiate polymerization reaction to form sol solution B;

[0048] 2) The 2.5D needle-punched integral felt with a density of 0.55g / cm3 is degummed at 800°C under an inert atmosphere in a vacuum carbon tube furnace, then immersed in sol solution B at 40°C for 20 minutes, taken out and dried at 80°C for 40 minutes, Repeat this treatment 4 times, and heat-treat the carbon felt after repeated impregnation and drying treatment in a nitrogen atmosphere at normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com