A preparation method of reinforced polycrystalline cubic boron nitride composite superhard material

A technology of cubic boron nitride and superhard materials, applied in the field of synthesis of polycrystalline cubic boron nitride composite superhard materials, to achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

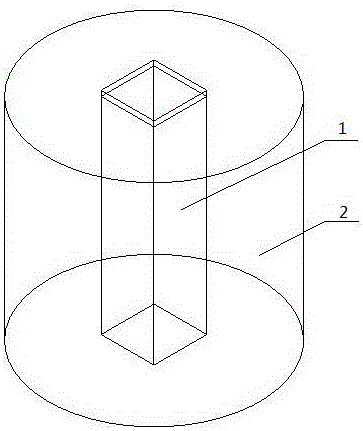

[0027] 1. Use a laser cutting machine to cut cubic boron carbonitride into small square columns of 1×1×4mm.

[0028] 2. Powder configuration:

[0029] Proportion cBN according to the proportion of particle size of 1-2 μm, 5-10 μm, 20-30 μm and its mass proportion is 15%, 25% and 60% respectively; carry out purification treatment on cBN, first carry out alkali treatment and then carry out acid treatment; Alkali treatment is to mix solid NaOH or KOH with cBN according to the weight ratio of 1:1, put it into a muffle furnace, keep it warm at 350°C for 1 hour, and then rinse it with hot water until neutral; acid treatment is to mix alkali Pour the treated cBN into a large volume beaker, add nitric acid 2-3cm higher than cBN and boil for 20 minutes, pour off the nitric acid, add more hydrochloric acid and boil for 20 minutes, wash with distilled water until neutral.

[0030] Al and Al 2 o 3 , SiC is mixed according to the weight ratio of 2:1:1 as an adhesive, and the adhesive is...

Embodiment 2

[0035] 1. Use a laser cutting machine to cut boron carbide into small cylinders of Φ1×4mm.

[0036] 2. Powder configuration:

[0037] Proportion cBN according to the particle size of 1-2μm, 5-10μm, 20-30μm, and its mass proportion is 10%, 30% and 60% respectively; the cBN is purified, first alkali treatment and then acid treatment; Alkali treatment is to mix solid NaOH or KOH with cBN according to the weight ratio of 1:1, put it into a muffle furnace, keep it warm at 350°C for 1 hour, and then rinse it with hot water until neutral; acid treatment is to mix alkali Pour the treated cBN into a large volume beaker, add nitric acid 2-3cm higher than cBN and boil for 20 minutes, pour off the nitric acid, add more hydrochloric acid and boil for 20 minutes, wash with distilled water until neutral.

[0038] Mix Al and SiC in a ratio of 1:1 as a binder, and the binder is mechanically treated in a vacuum ball mill and ball milled for 48 hours;

[0039] Mix cBN and adhesive according to...

Embodiment 3

[0043] 1. Use a laser cutting machine to cut nano-twinned cubic boron nitride into triangular prisms with a side length of 1.2mm and a height of 4mm;

[0044] 2. Powder configuration:

[0045] Proportion cBN according to the particle size of 1-2 μm, 5-10 μm, 20-30 μm, and its mass proportion is 12%, 32% and 56% respectively; the cBN is purified, first alkali treatment and then acid treatment; Alkali treatment is to mix solid NaOH or KOH with cBN according to the weight ratio of 1:1, put it into a muffle furnace, keep it warm at 350°C for 1 hour, and then rinse it with hot water until neutral; acid treatment is to mix alkali Pour the treated cBN into a large volume beaker, add nitric acid 2-3cm higher than cBN and boil for 20 minutes, pour off the nitric acid, add more hydrochloric acid and boil for 20 minutes, wash with distilled water until neutral.

[0046] Al, Ti and SiC, Al 4 N 3 According to the weight ratio of 1:1:1:1, it is mixed as an adhesive, and the adhesive is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com