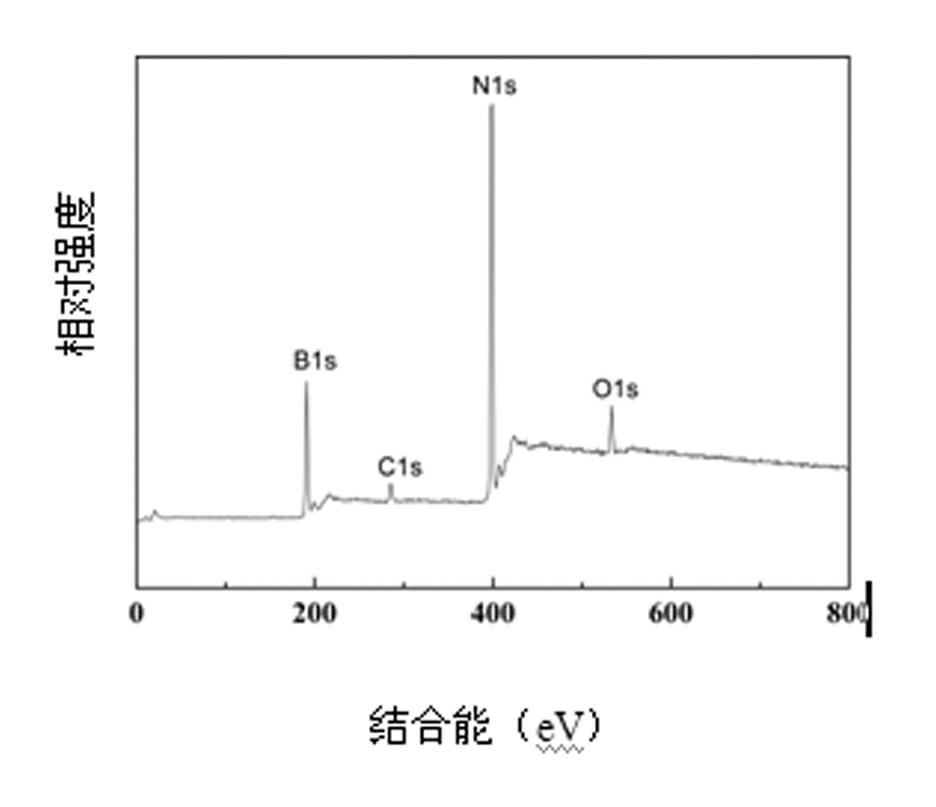

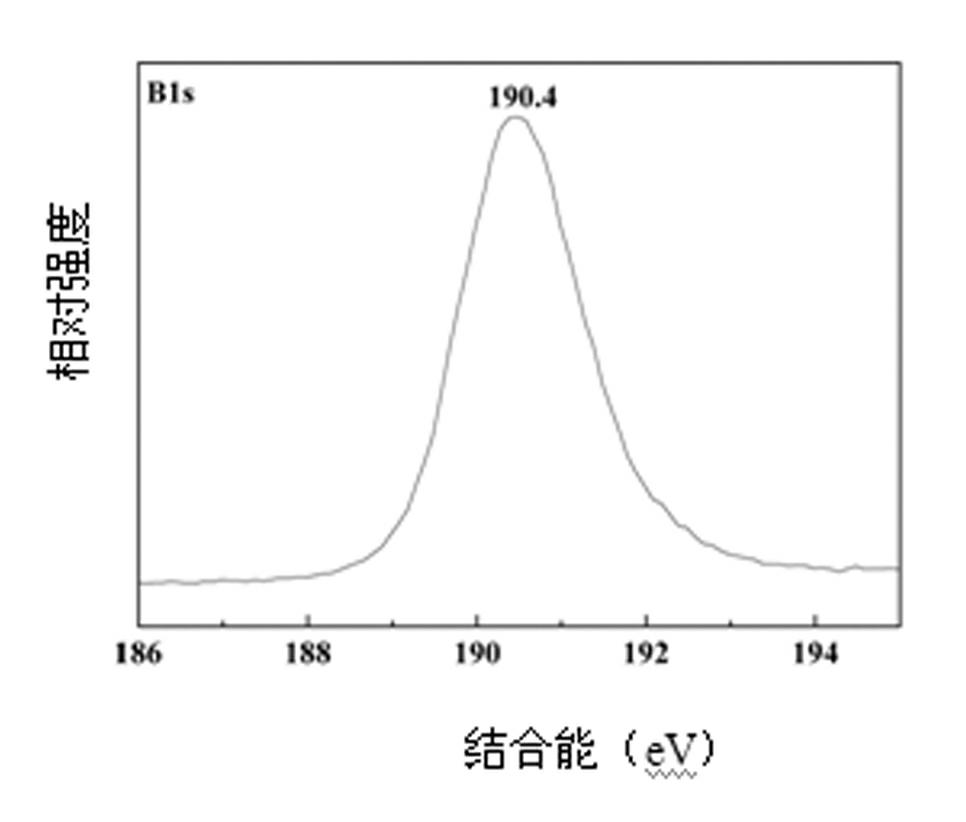

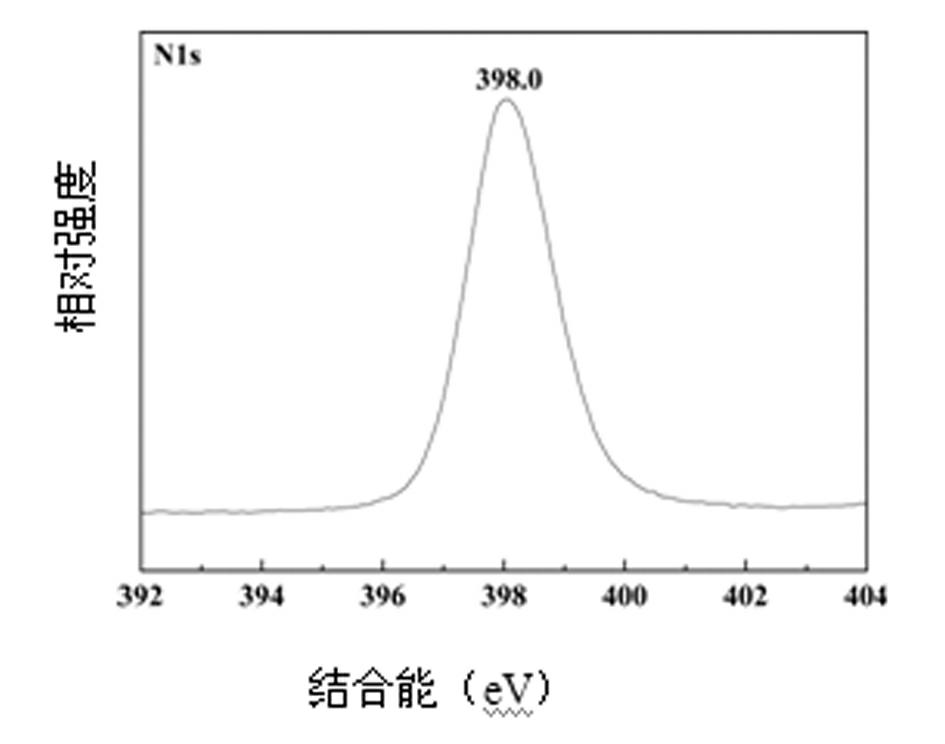

Method for preparing boron nitride nanorod by using precursor conversion method

A technology of precursor conversion and boron nitride, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of no reports, etc., and achieve the effect of low production cost, high purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Soak the carbon nanotubes in concentrated nitric acid at 60°C for 10 hours, wash them with water and dry them;

[0025] (2) Dissolve polyalkylaminoborazine in xylene to prepare a solution with a concentration of 30% by mass. Immerse the dried carbon nanotubes in the mixed solution for 15 hours by vacuum impregnation, and separate the solid and liquid by suction filtration under reduced pressure;

[0026] (4) Put the solid obtained in step (2) into a vacuum oven and dry at 100°C for 3 hours;

[0027] (5) Put the cooled solid into a high-temperature furnace in dry ammonia at 80°C for 1 hour;

[0028] (6) Raise the temperature to 1000°C at a rate of 300°C / h and keep it warm for 3h to crack the alkylamino borazine and remove carbon elements at the same time to prepare BN nanorods with a diameter of 30-50 nm.

Embodiment 2

[0030] (1) Soak the carbon nanotubes in concentrated nitric acid at 60°C for 15 hours, wash them with water and dry them;

[0031] (2) Dissolve polyalkylaminoborazine in toluene, an organic solvent, and prepare a mass percent concentration of

[0032] Materials, wave-transparent materials, etc., have broad application prospects.

specific Embodiment approach

[0033] The present invention will be further described below in conjunction with embodiment. However, the examples should not be construed as limiting the protection scope of the present invention, and methods equivalent thereto are within the protection scope of the present invention.

[0034] Example 1:

[0035] (1) Synthesize the polyalkylaminoborazine precursor with the following structural formula according to the prior art: (for synthesis see Chinese Chem. Lett. , 21, 1079 (2010), its softening point is about 75℃,

[0036]

[0037] (2) Grind the polyalkylaminoborazine precursor in a glove box under the protection of Ar gas, and sieve it with 1000 mesh; put the sieved precursor powder in a graphite boat, and in a tube furnace, In a high-purity nitrogen atmosphere, heat up to 150°C at a heating rate of 4°C / min, with a nitrogen flow rate of 60ml / min, and keep warm for 1h; then heat up to 600°C at a heating rate of 5°C / min, and keep warm for 2h; Min heating rate, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com