Uranium dioxide-based fuel pellet with adjustable thermal expansion coefficient and enhanced thermal conductivity, and preparation method thereof

A technology of thermal expansion coefficient and uranium dioxide, which is applied in the field of reactor fission materials, can solve the problems of mismatching thermal expansion coefficient, affecting the stable service of fuel pellets, residual thermal stress, etc., so as to delay the air gap closing time, reduce residual thermal stress, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a uranium dioxide-based fuel pellet with adjustable coefficient of thermal expansion and enhanced thermal conductivity of the present invention, specifically:

[0028] 1) Add uranium dioxide raw material powder, metal beryllium powder and molybdenum powder in a volume ratio of 75:10:15 to a nylon tank for wet mixing, wherein the grinding medium is absolute ethanol, the wet mixing time is 24 hours, and the rotation speed is 120r / min; then vacuum dry to get evenly mixed UO 2 - Be-Mo blanks.

[0029] 2) The UO obtained in step 1 2 - Be-Mo blanks are put into graphite molds for densification by spark plasma sintering, the sintering atmosphere is vacuum, the sintering temperature is 900°C, the heating rate is 50°C / min, the holding time is 30min, and the pressure is 80MPa, The vacuum degree is 0.5Pa, and then the film is removed and the size is processed.

[0030] After determination, the thermal conductivity of the sample prepared in this embodim...

Embodiment 2

[0032] This embodiment discloses a uranium dioxide-based fuel pellet with adjustable coefficient of thermal expansion and enhanced thermal conductivity of the present invention, specifically:

[0033] 1) Add uranium dioxide microspheres, metal beryllium powder and molybdenum powder into a nylon tank in a volume ratio of 85:5:10, and dry mix. The mixing method with beryllium powder and molybdenum powder is dry mixing without adding any Grinding media and balls, the dry mixing time is 0.5h, and the rotation speed is 300r / min. Get a homogeneously mixed UO 2 - Be-Mo blanks.

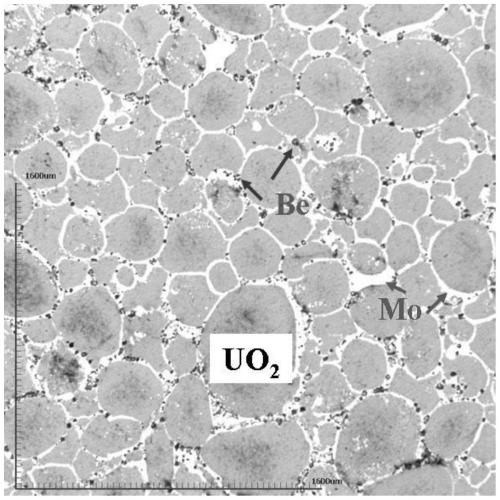

[0034] 2) The UO obtained in step 1 2 - Be-Mo blanks are put into graphite molds for densification by spark plasma sintering, the sintering atmosphere is vacuum, the sintering temperature is 1250°C, the heating rate is 300°C / min, the holding time is 2min, and the pressure is 30MPa, The vacuum degree is 20Pa, and then the film is released. Dimensions can be processed, the microstructure such as figure 1 s...

Embodiment 3

[0037] This embodiment discloses a uranium dioxide-based fuel pellet with adjustable coefficient of thermal expansion and enhanced thermal conductivity of the present invention, specifically:

[0038]1) Add uranium dioxide raw material powder, metal beryllium powder and molybdenum powder in a volume ratio of 90:2:8, add them to a nylon tank, and wet mix them. The grinding medium is absolute ethanol. The wet mixing time is 15 hours, and the rotation speed is 220r / min; then vacuum dry to get evenly mixed UO 2 - Be-Mo blanks.

[0039] 2) The UO obtained in step 1 2 - Be-Mo billets are put into a hot-pressing mold for hot-pressing sintering, the sintering atmosphere is argon, the sintering temperature is 1280°C, the heating rate is 50°C / min, the holding time is 0.5h, and the pressure is 50MPa. Then remove the film and size processing.

[0040] After determination, the thermal conductivity of the sample prepared in this embodiment is more than 180% (800-1000° C.) of the thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com