Automatic bending and blanking device

A blanking and equipment technology, applied in the field of pipe bending, can solve the problems of complicated operation, operator injury when taking out, manual pipe taking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

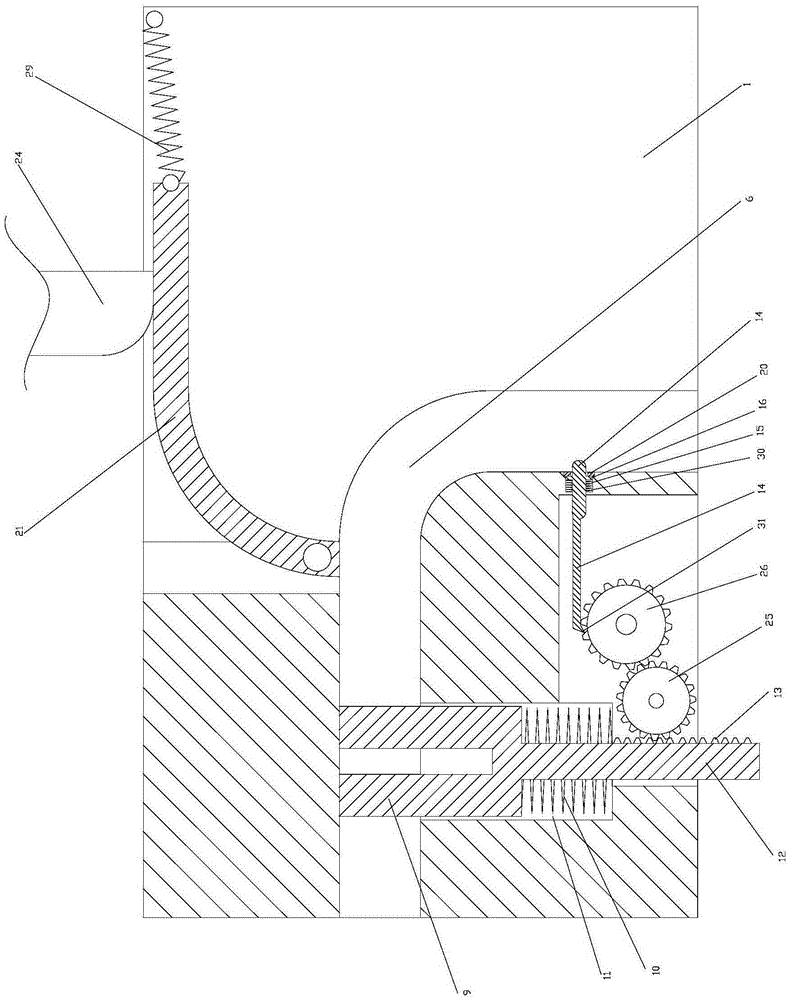

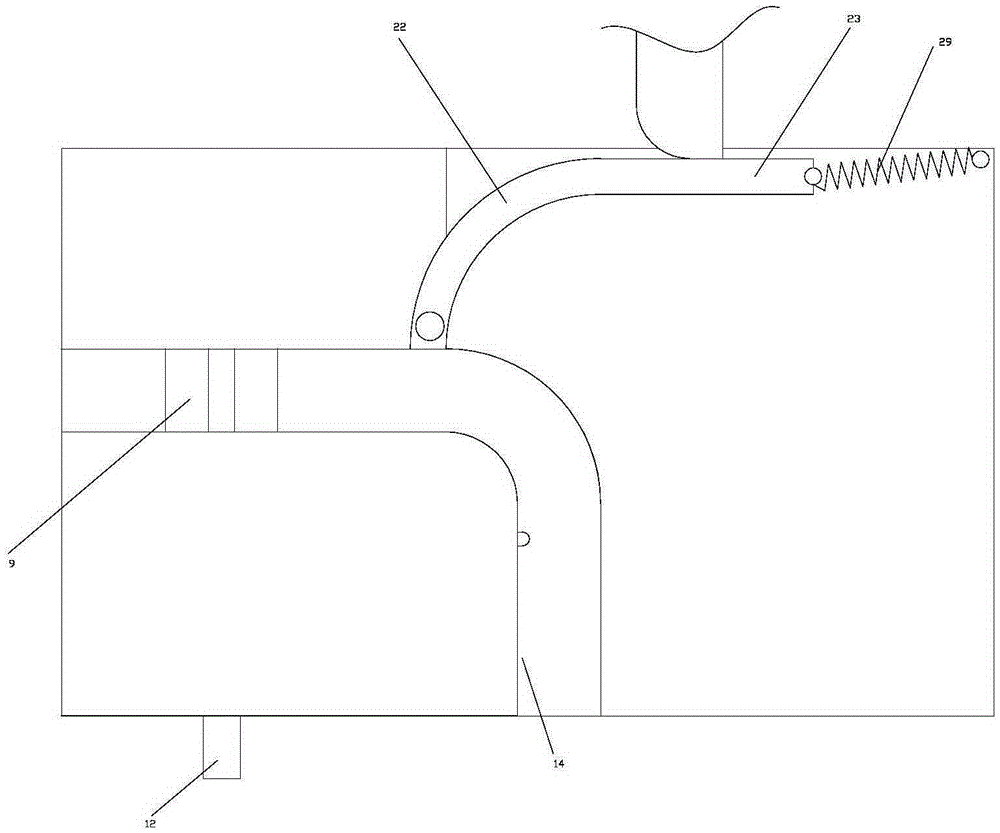

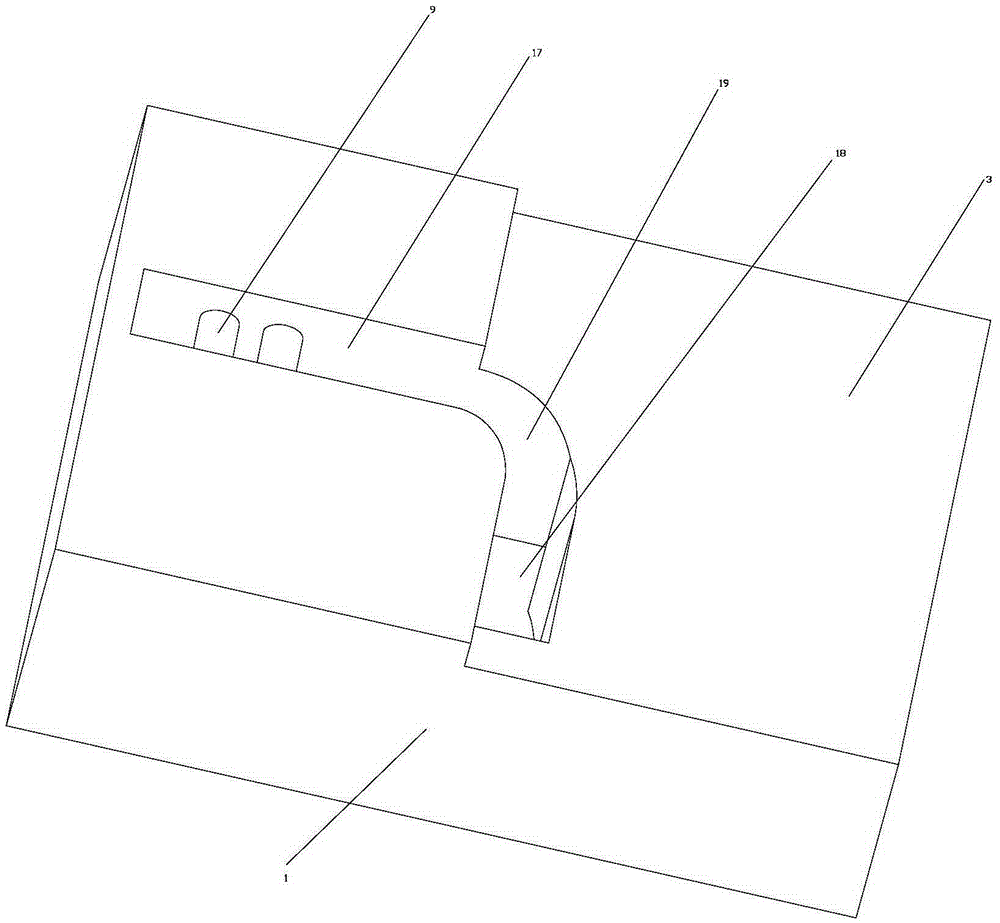

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] As shown in the figure, the working principle of the present invention is as follows: Firstly, push the slide bar until the end of the cylindrical pin abuts against the inner wall of the first through hole. The sliding rod can move the convex teeth and the ejector rod through the transmission of the linear rack and the first gear and the second gear. The convex teeth and the ejector rod can only be displaced periodically in one direction, while the convex teeth and the ejector rod can always be locked under the action of the compression spring. Connected to the second gear to prevent the slide bar from resetting automatically due to the reverse rotation of the second gear; then place one end of the unbent pipe in the opening on the boss and above the cylindrical pin, and place the other end horizontally on the Datum planes on the base, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com