Automatic tissue rolling mechanism and wet tissue machine

An automatic technology for roll towels, applied in the direction of winding strips, thin material processing, household appliances, etc., can solve the problem of limited length range of wet wipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings.

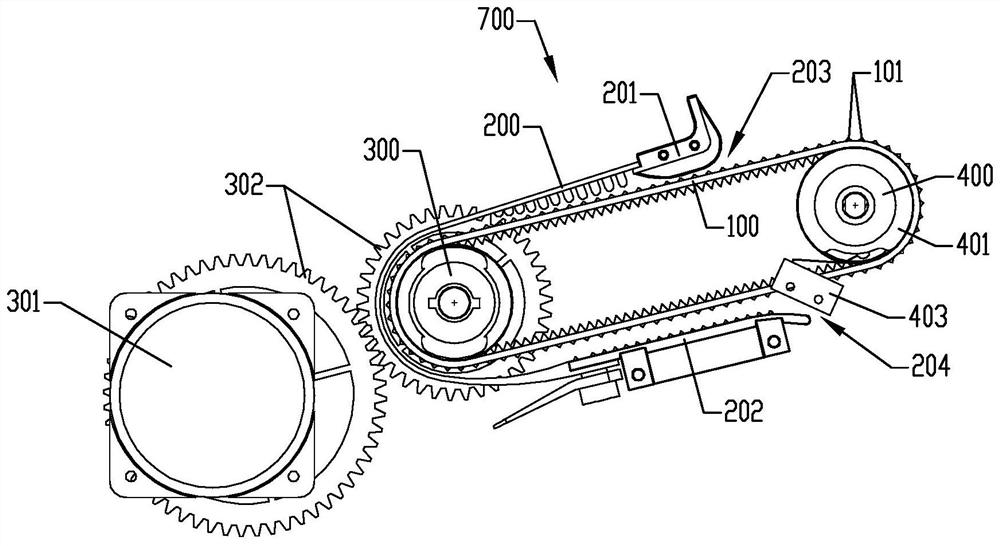

[0033] Such as figure 1 , Figure 4-5 As shown, the automatic roll mechanism includes a inner track 100, an outer track 200, a drive shaft 300, a driven shaft 400, and a power.

[0034] The driving force is composed of the motor 301 and the gear 302, one of which is fitted at one end of the drive shaft 300, and the motor rotates to rotate with the drive shaft by the gear drive.

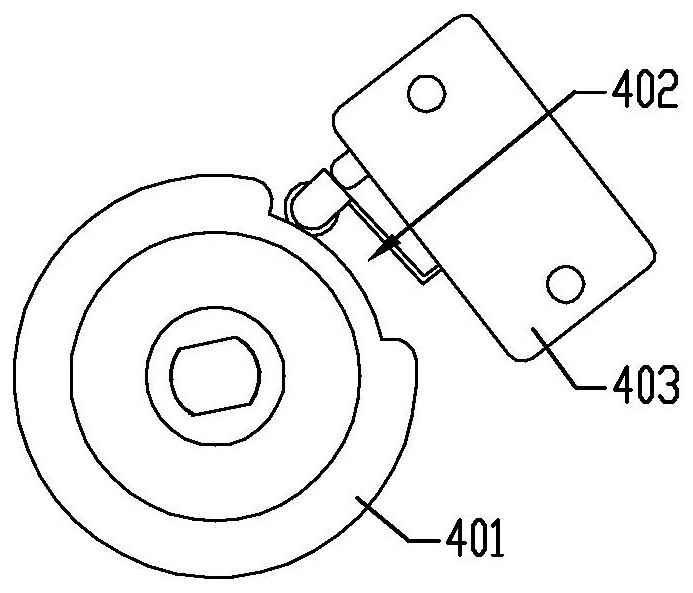

[0035] The drive shaft 300, the driven shaft 400 is parallel, and both ends are rotated on the left side plate 501, the right side plate 502. The left end of the driven shaft is configured with a concave cam 401 that has a gap 402 of the peripheral surface of the concave cam. In order to alleviate the drive shaft, the weight of the driven shaft itself is made into hollow, non-solid structure.

[0036] The inner track 100 is ring-shaped and is sleeved on the drive shaft 300 and the driven shaft 400, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com