Plugging technology of high infiltration layer

A kind of process and water layer technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of failure to restore production capacity, high price, high cost, etc., and achieve good unidirectionality and Sealing performance, damage prevention, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail through specific embodiments below.

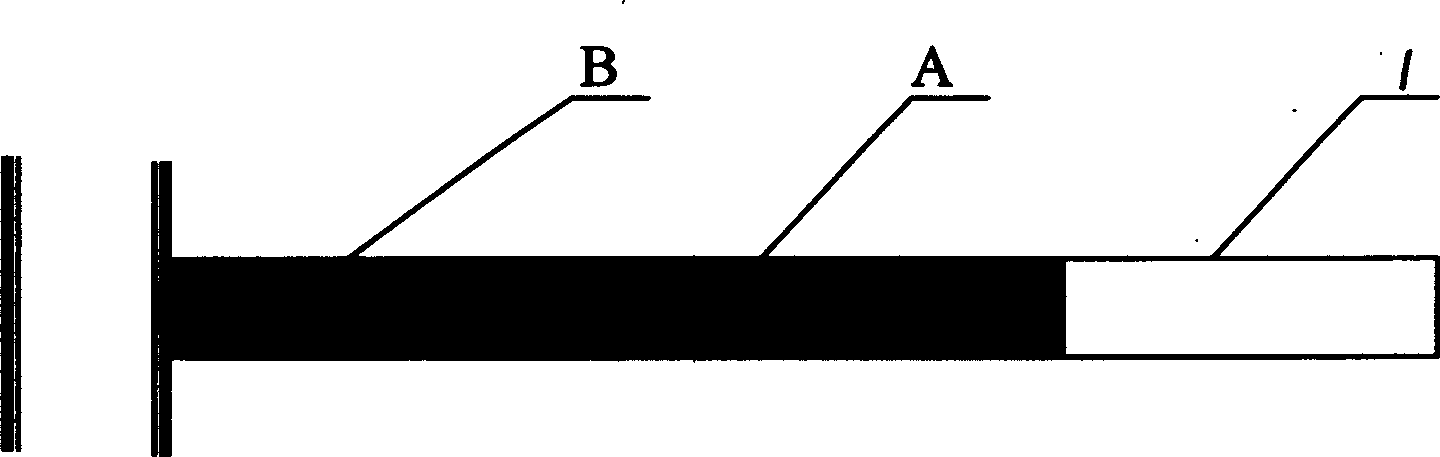

[0012] as illustrated, figure 1 The shown embodiment one includes a plugging layer composed of two plugging materials, wherein A is a dispersion fluid prepared from waste drilling polymer mud and adding 0.1% lignosulfonate as a mud diluent-1 , B is the dispersant fluid-2 prepared from oilfield waste oil sludge accounting for about 39% of the total weight, 60% of sewage and 1% of OP-type surfactant as a dispersant, and the two plugging materials are injected sequentially, After the construction is completed, the boring well can enter the steam chemical injection process within 5-7 days. 1 in the figure is the edge water of the formation.

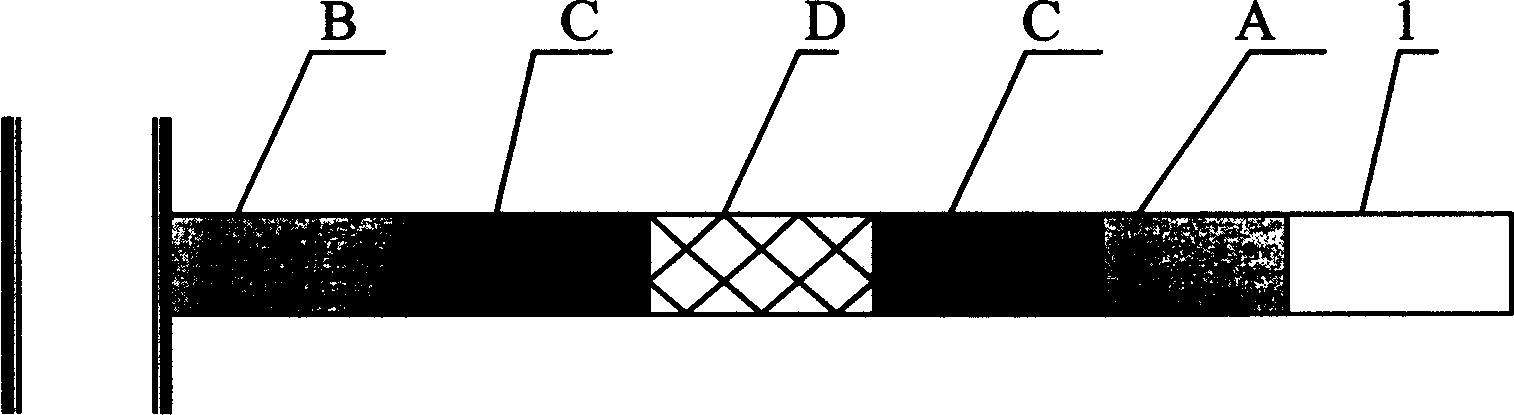

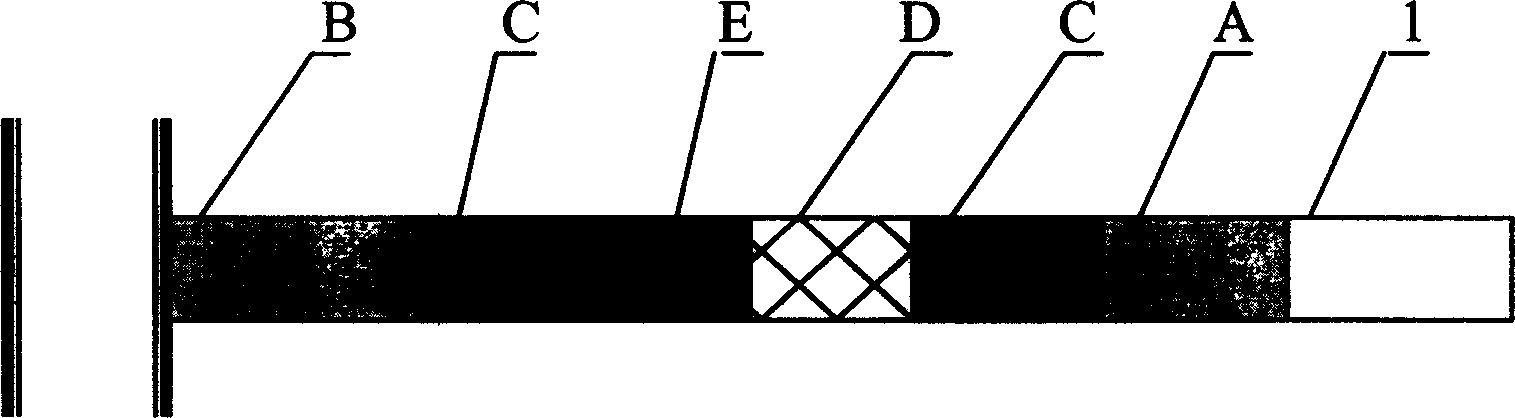

[0013] Depend on figure 2 The shown embodiment two except that A is the dispersion fluid-1 prepared by waste drilling polymer mud and adding lignosulfonate accounting for 3% of polymer mud weight as mud diluent, and B is the total weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com