A Directional Output Ring Microcavity Laser

A laser and microcavity technology, applied in the field of annular microcavity lasers, can solve the problem of difficult coupling of light fields, and achieve good unidirectional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

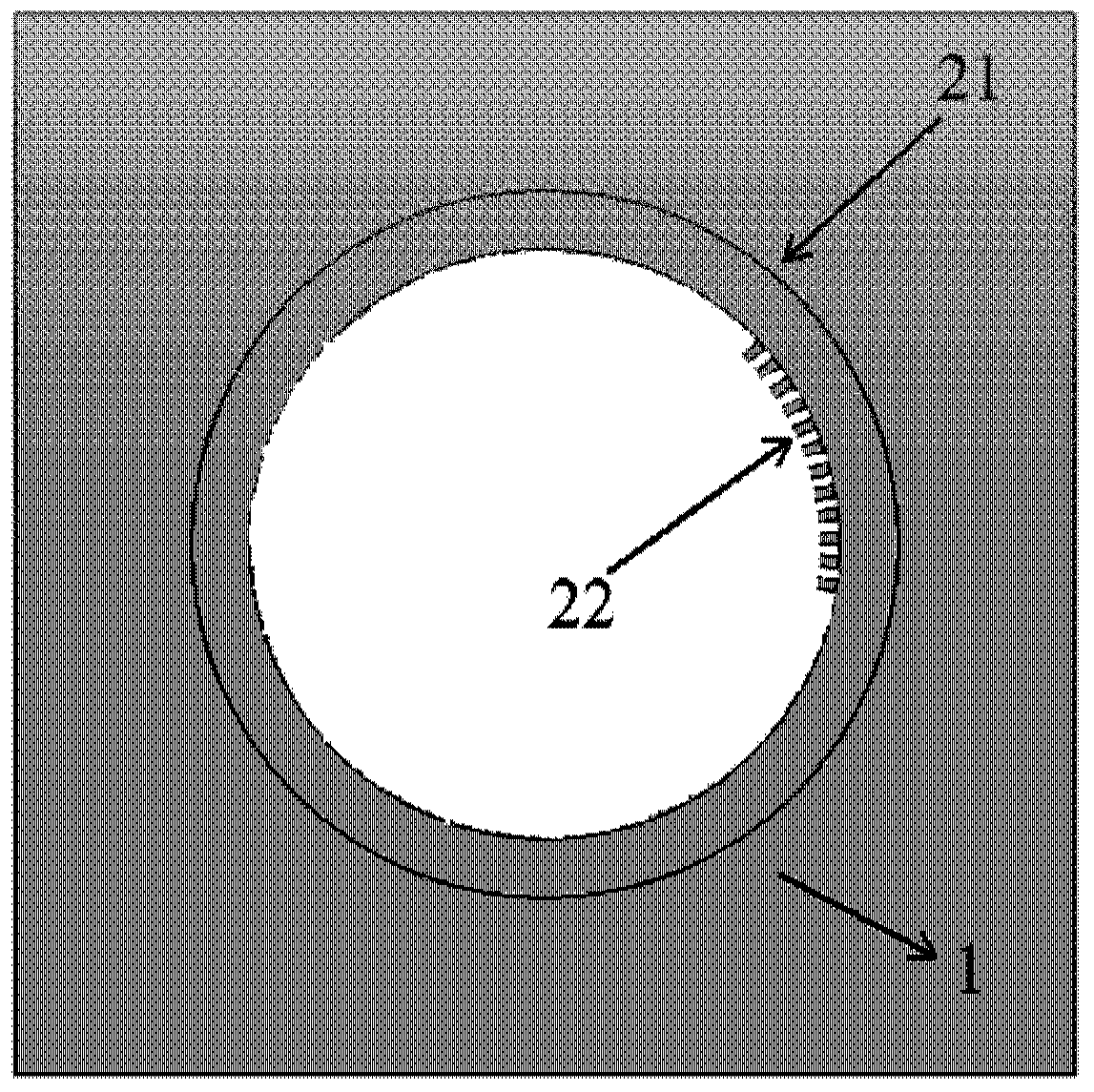

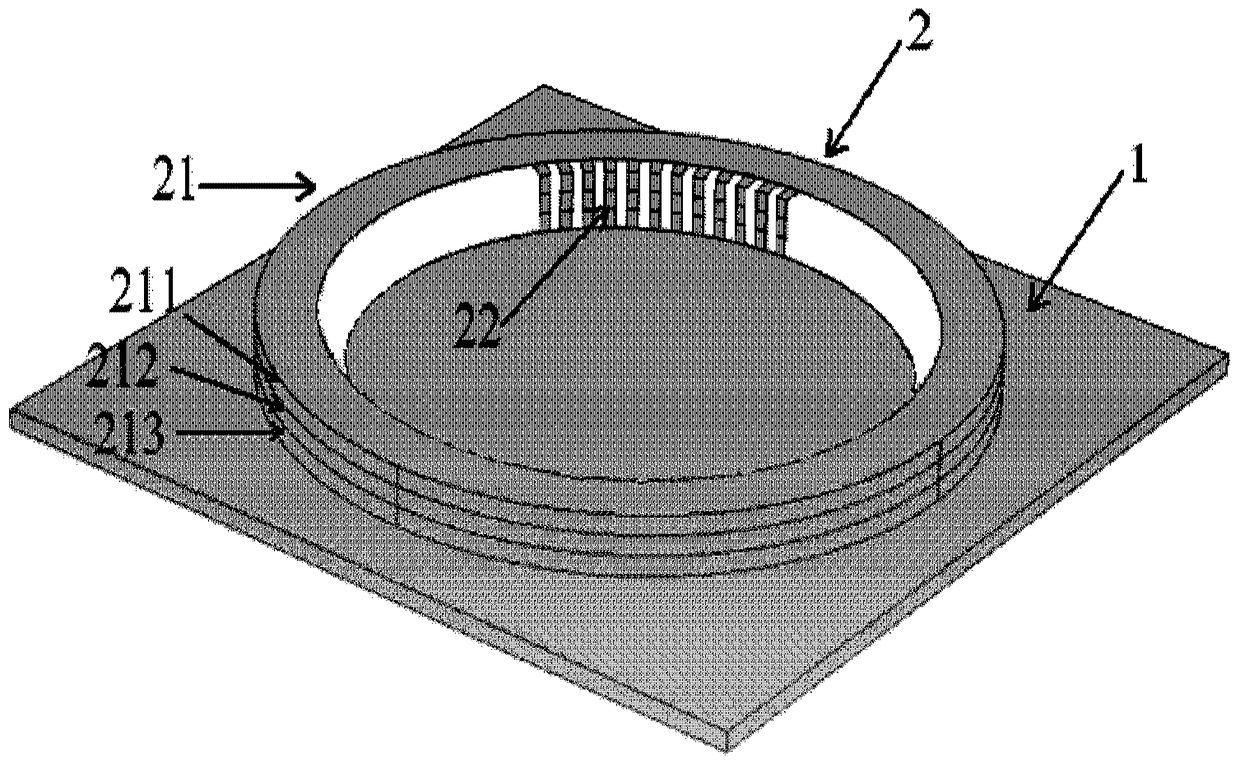

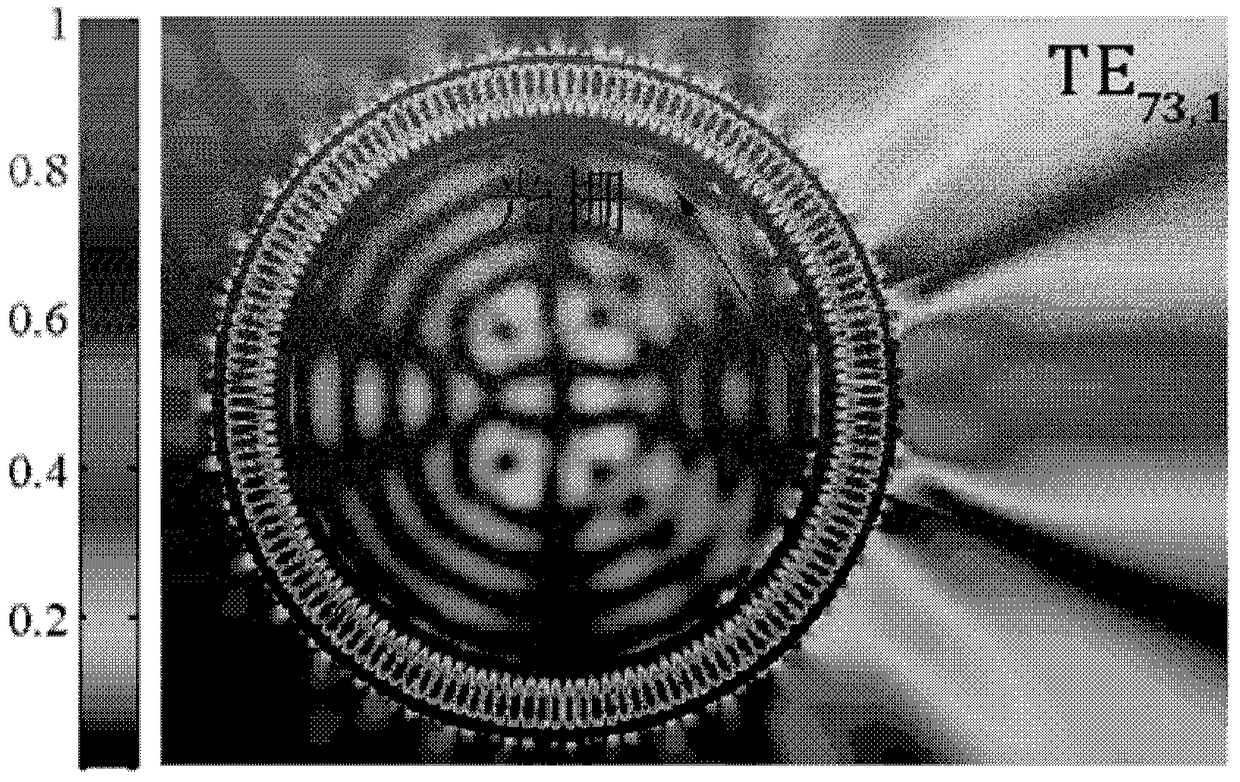

[0029] In order to make the object, technical scheme and advantages of the present invention clearer, below in conjunction with specific embodiment, and refer to Figure 1-Figure 6 Shown, the present invention is further described in detail.

[0030] The ring-shaped semiconductor microcavity laser with grating structure distributed on the inner wall part provided by the present invention controls the far-field output characteristics of different modes in the ring microcavity by selecting different numbers of gratings on the inner wall and the angular period of the grating. The partially distributed grating structure will inhibit the output of light in the area without grating distribution, so that the output of the light field is concentrated in the grating distribution area. Partially distributed gratings couple the WG mode to form a deformed WGM coupling mode containing low-order angular component components, which can realize directional output of the light field. By selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com