Design method and application of three-dimensional porous inclined array structure for directional transportation of liquid

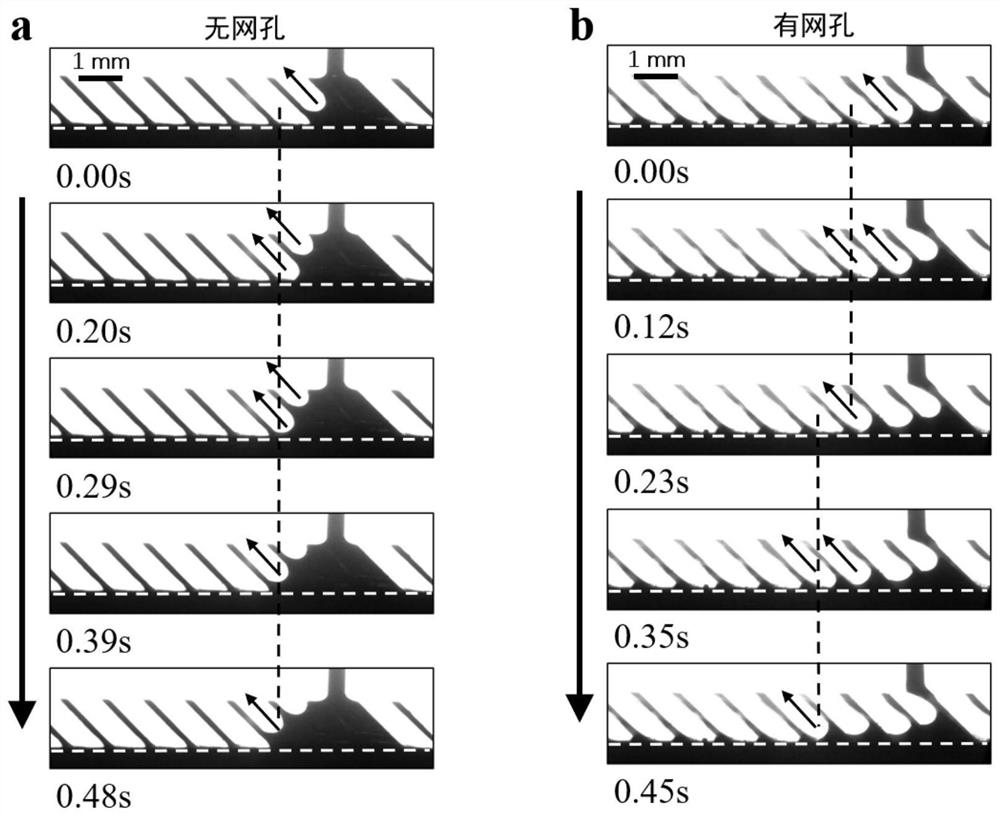

An array structure and porous structure technology, applied in the field of microfluidics, can solve the problems of uncontrollable liquid diffusion, limited application range, and inability to accurately control the position and speed of liquid directional transport, so as to overcome the structural strength too small and the application range Wider and easier to achieve effect of processing scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

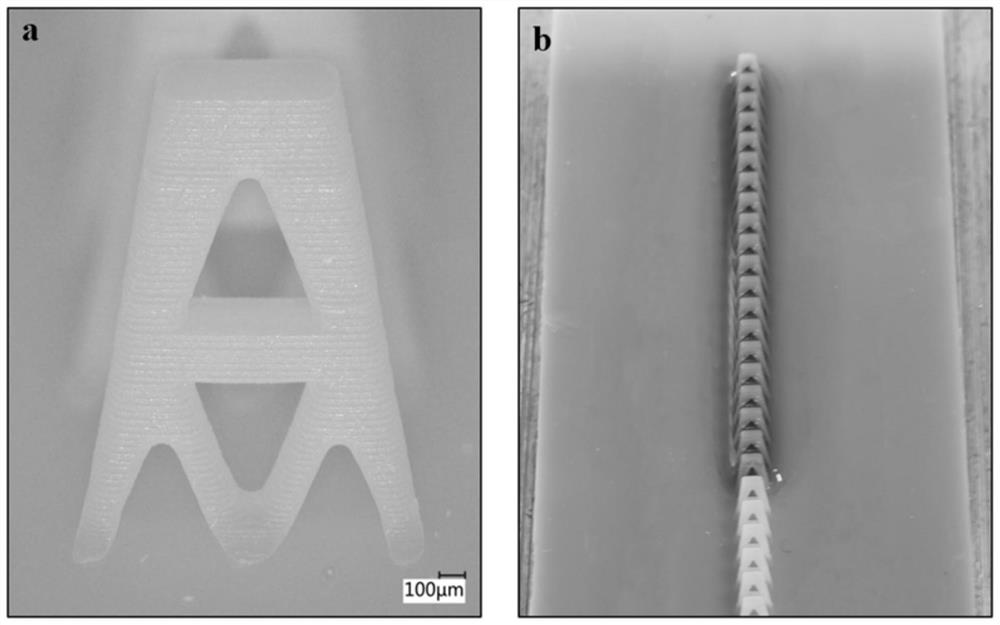

[0033] The preparation method of the discontinuous short rectangular scheme of the micron-scale porous tilted array structure is as follows:

[0034] It is prepared by light-curing 3D printing technology, and the selected material is red wax high-precision resin.

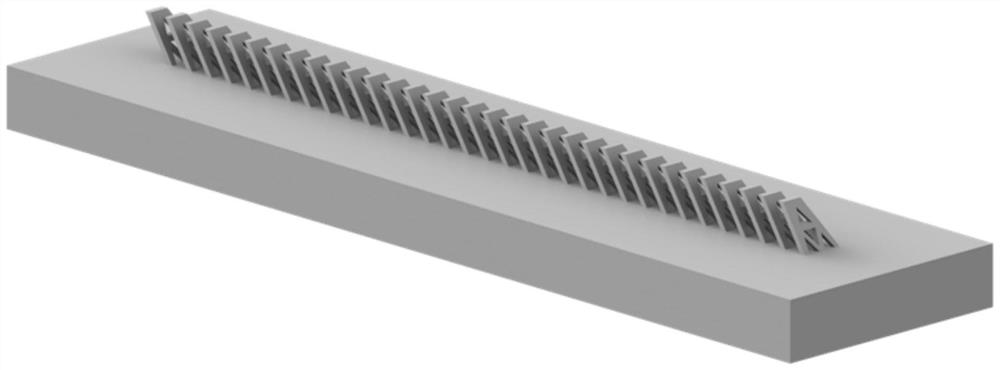

[0035] The first step is to use three-dimensional drawing software to draw the micron-scale porous tilted array structure. For the porous structure, equilateral triangular holes with a side length of 500 μm were selected, the number of holes was selected in two rows, and the spacing between the holes was selected as 150 μm. The single structure of the inclined structure is a trapezoid with a horizontal thickness of 230 μm and a vertical height of 1400 μm. The monomer structures are arranged in a horizontal and vertical repeating array to form a single-column micron-scale porous inclined array structure.

[0036] The second step is to slice the drawn model. At the same time, considering the expansion law of 3D pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com