Bending discharging device

A blanking and equipment technology, applied in the field of pipe bending, can solve the problems of complex operation, high maintenance cost, unreliable work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

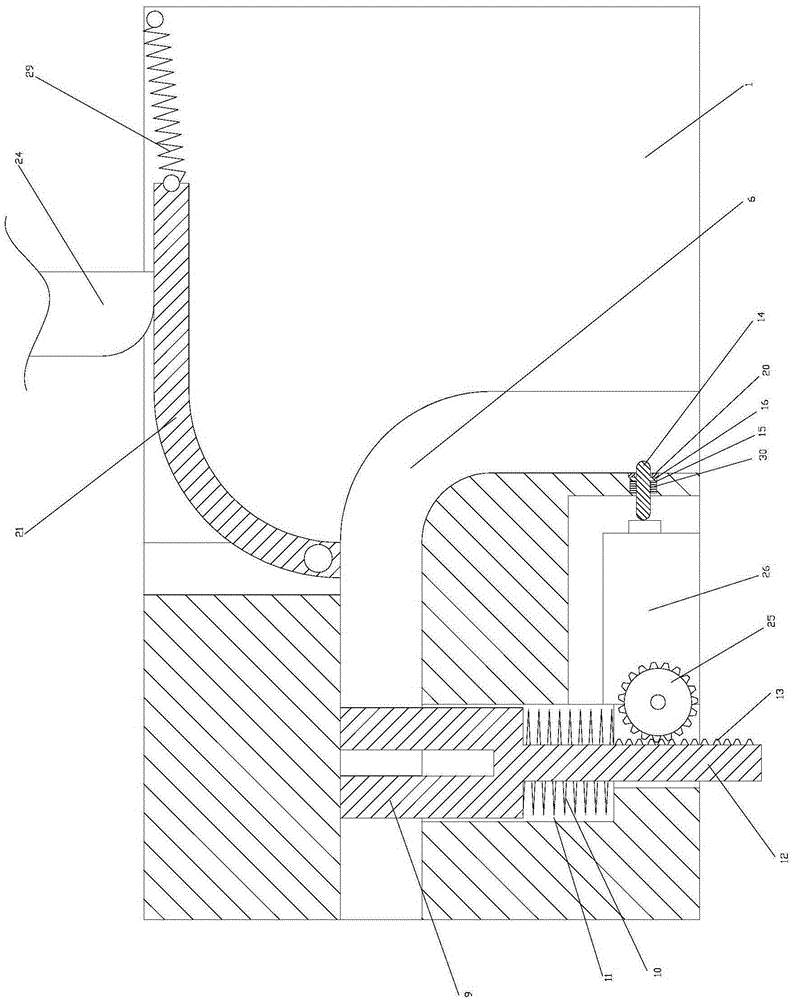

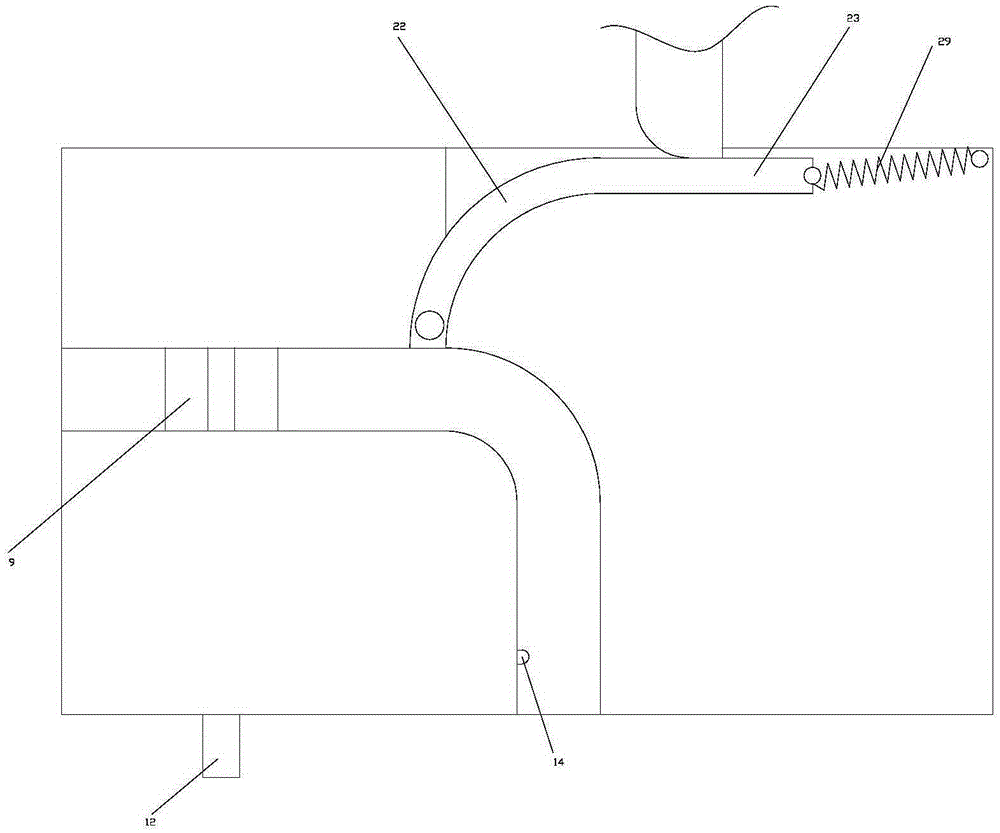

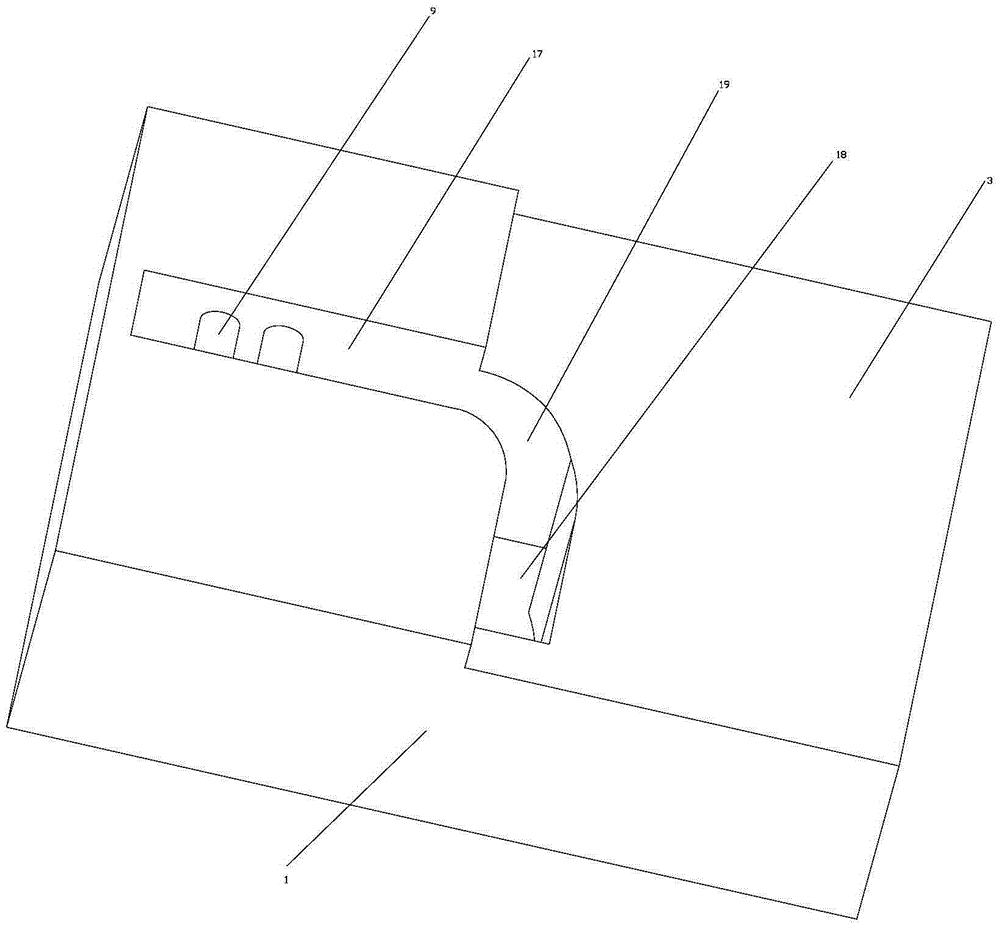

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] As shown in the figure, the working principle of the present invention: first, the cylindrical pin is displaced under the pressure of the first compression spring until the end of the cylindrical pin abuts against the inner wall of the first through hole; then one end of the unbent pipe is placed on the In the opening on the boss and above the cylindrical pin, the other end is placed horizontally on the reference surface on the base, such as Figure 4 shown;

[0018] Then, the punch on the hydraulic machine tool works to drive the rotating plate to rotate, so that the pipe is bent to conform to the shape of the through hole, such as Figure 5 As shown; during the rotation of the rotating plate, the third tension spring will also be pulled open, so that the third tension spring is deformed to reserve the force required for the reset of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com