Imitated silk high-elasticity knitted underwear fabric and preparation method thereof

A technology for underwear fabrics and artificial silk, applied in underwear, knitting, weft knitting and other directions, can solve the problems of fast coloring of cupro fibers, low strength of cupro fibers, poor wear resistance, etc. The effect of uneven dyeing and full appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

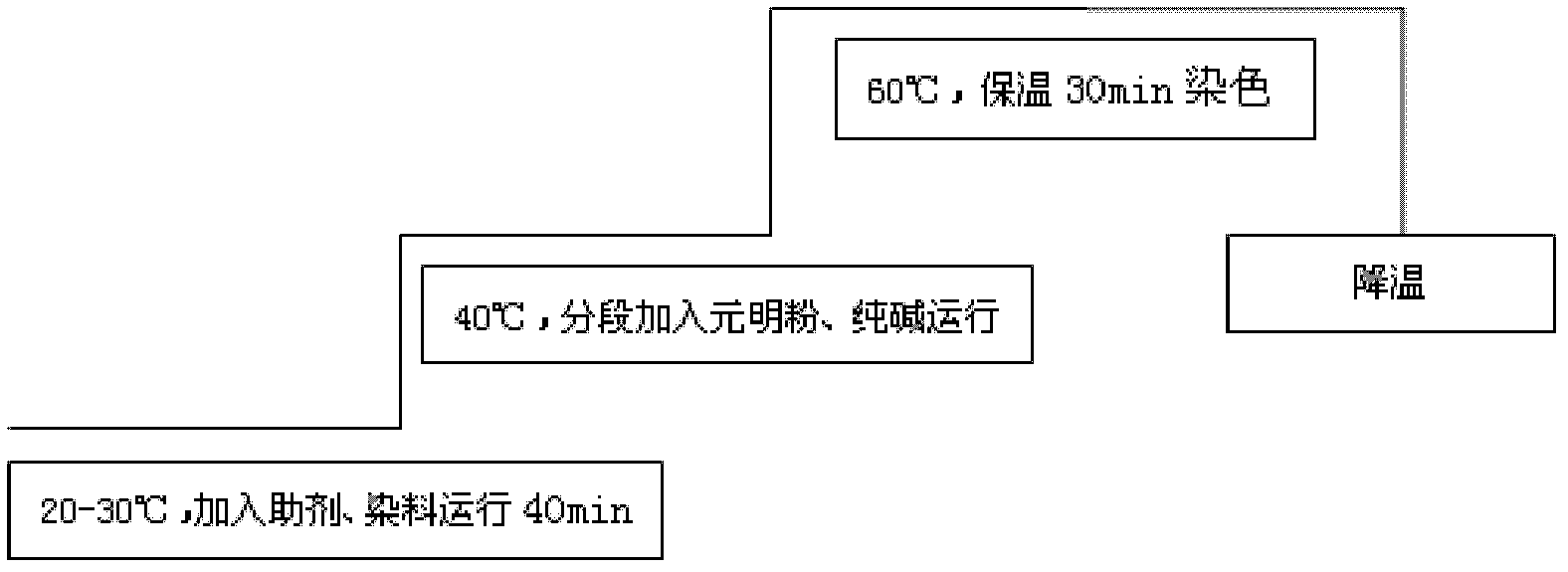

[0034] Step 1: Raw material preparation: cupro / nylon blended filament with a linear density of 111dtex and a cupro fiber content of 68%; the spandex yarn is made of silk with easy low-temperature setting performance and its linear density is 22dtex.

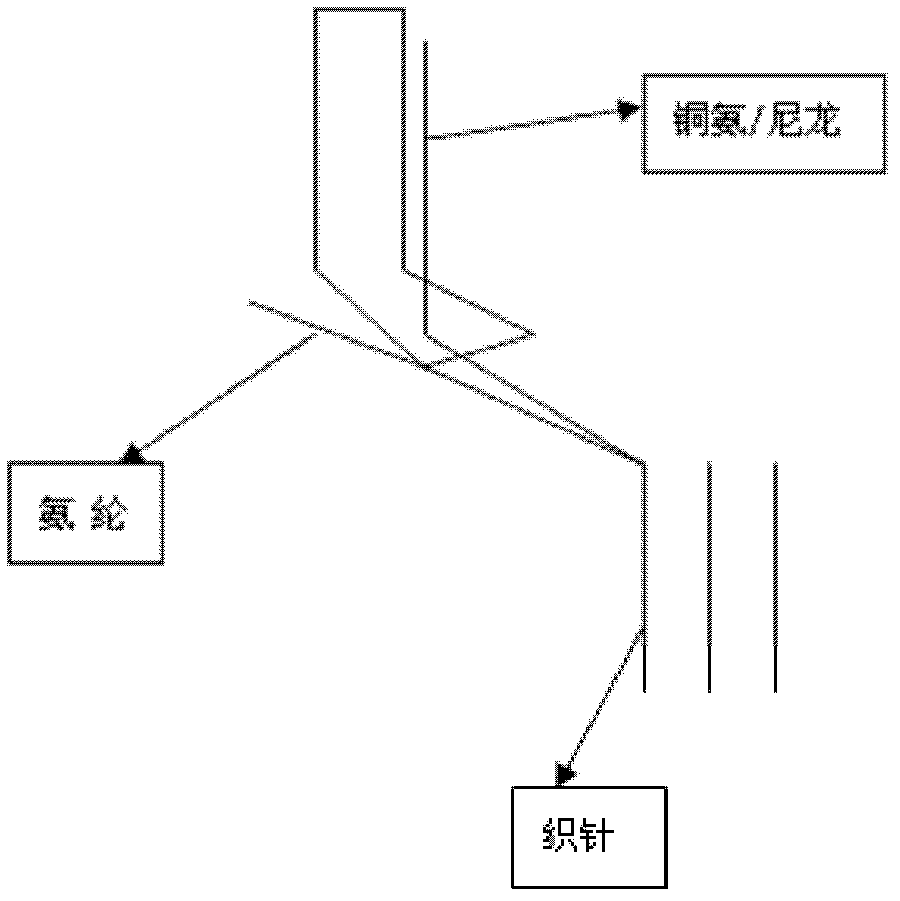

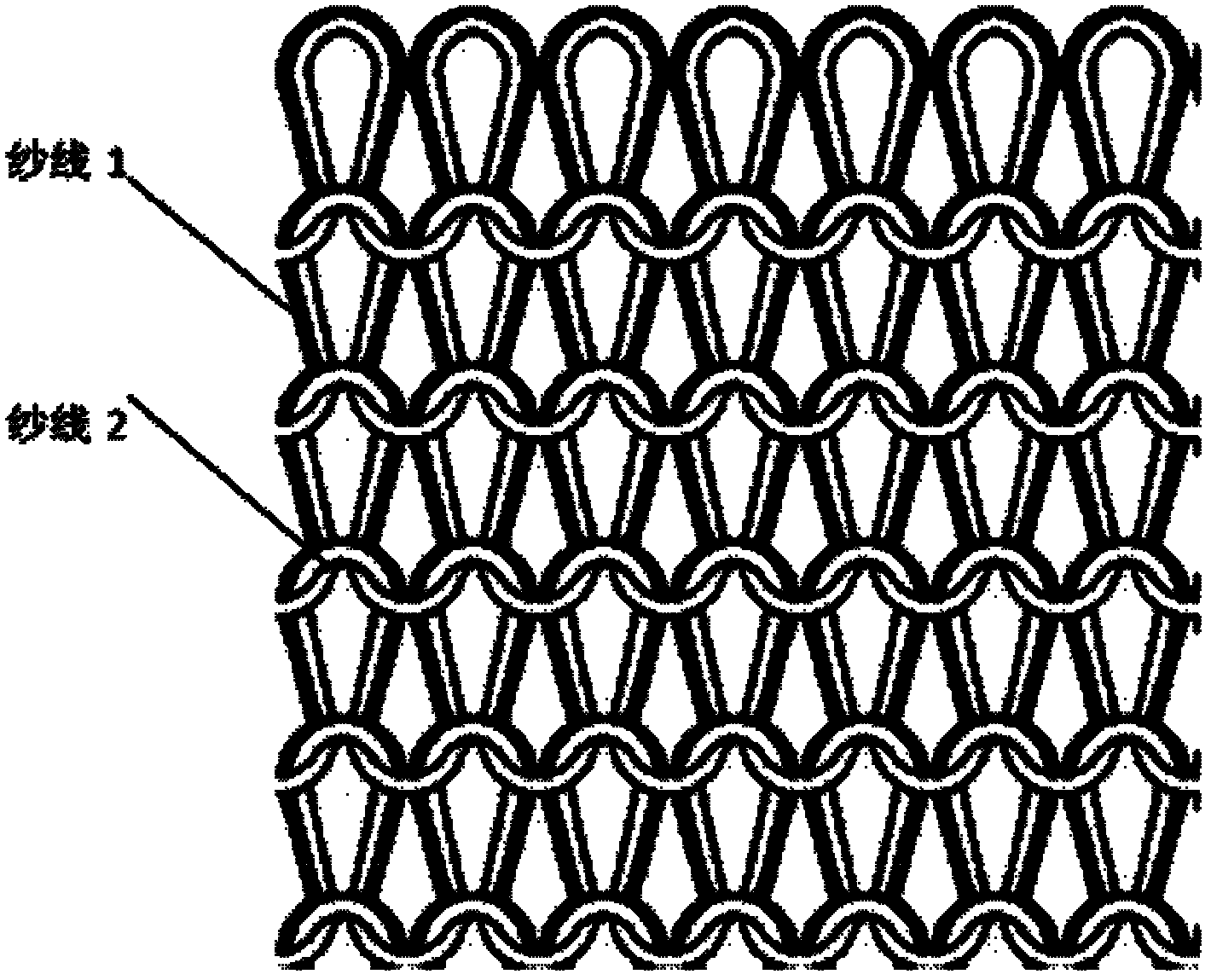

[0035] Step 2: Weaving on the machine: choose a 28G large circular machine for weaving, the tension on the cupro / nylon blended filament machine is 5 grams force, and ensure that the longitudinal angle of the cupro / nylon blended filament fed into the needle hook is larger than the spandex filament Feed the yarn vertically so that the cupro / nylon is on the front of the fabric. Active yarn feeding method is used to make the copper ammonia / nylon filament coil length 15cm / 50w, the spandex coil length is 5cm / 50w of the copper ammonia / nylon blended filament coil length, and the finished fabric weight is 150g / m 2 .

[0036] Step 3: Cut and roll on the machine to ensure the flatness of the cloth surface and avoid creases on the cloth sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com