Clutch self-calibration method of hybrid electric vehicle and application of clutch self-calibration method

A hybrid vehicle and clutch technology, applied in the field of clutch self-calibration and clutch self-calibration of hybrid vehicles, can solve the problems of vibration, temperature change, electromagnetic interference, underutilization, increased vehicle weight and cost, etc. Weight and cost, effect of accurate separation or engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

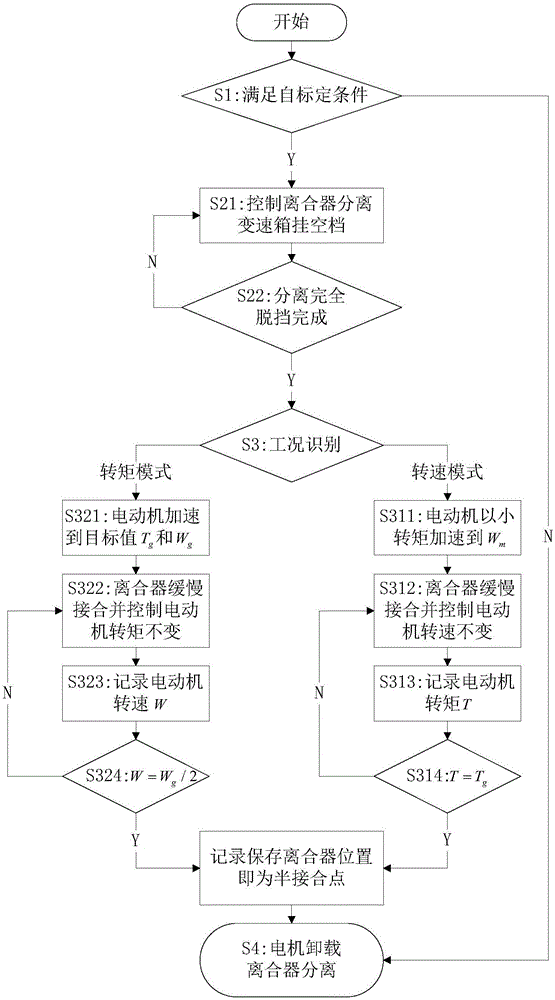

[0048] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0049] A clutch self-calibration method of a hybrid vehicle, the concrete steps of the clutch self-calibration method are as follows:

[0050] S1. Judging whether the hybrid electric vehicle satisfies the self-calibration condition. The self-learning conditions include: the accumulative deviation between the clutch position measured by the displacement sensor and the clutch position at the last calibration of the TCU exceeds the allowable range (within the range, it can be considered that the torque output by the engine can be fully transmitted to the transmission); The switch is in the OFF position. Although the key switch is in the OFF position, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com