Actuator system for hydraulic clutch actuation

A technology for actuating systems and clutches, applied to clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as inability to ensure hydraulic fluid pressure or predetermined volume, and achieve accurate engagement or separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

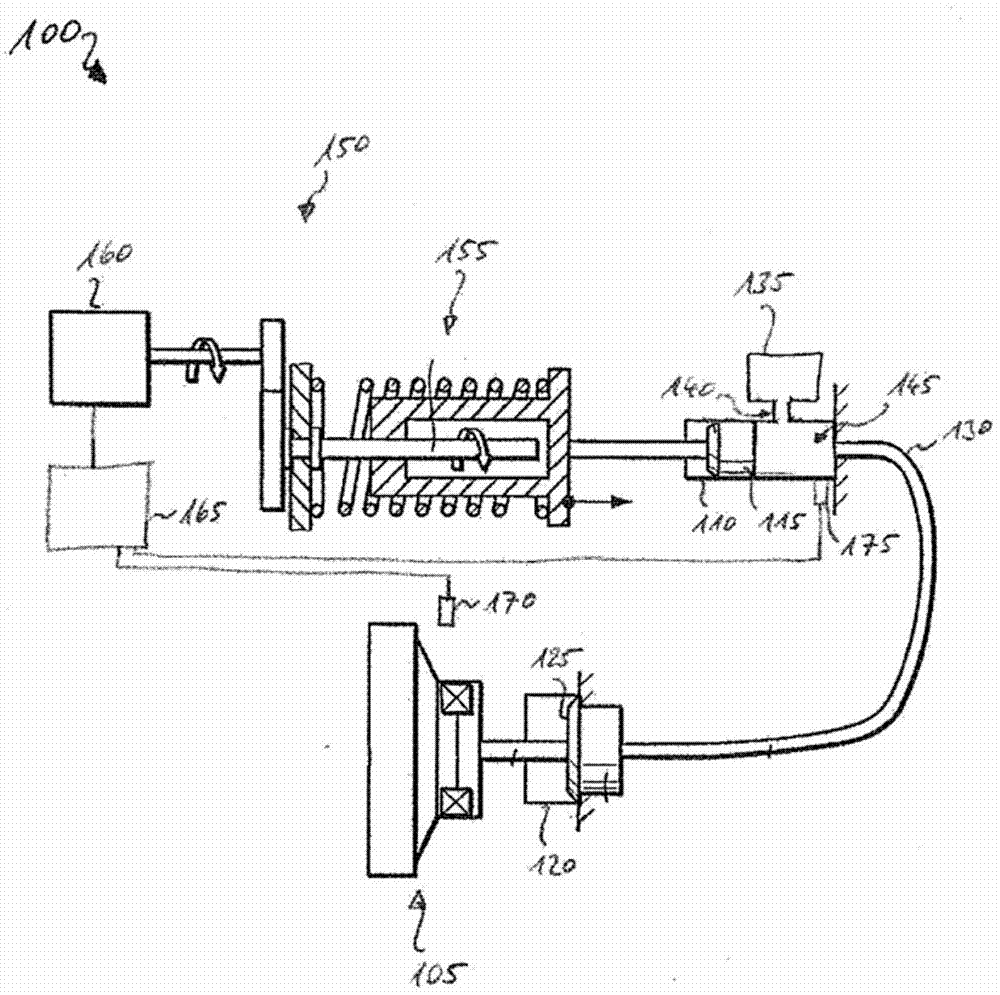

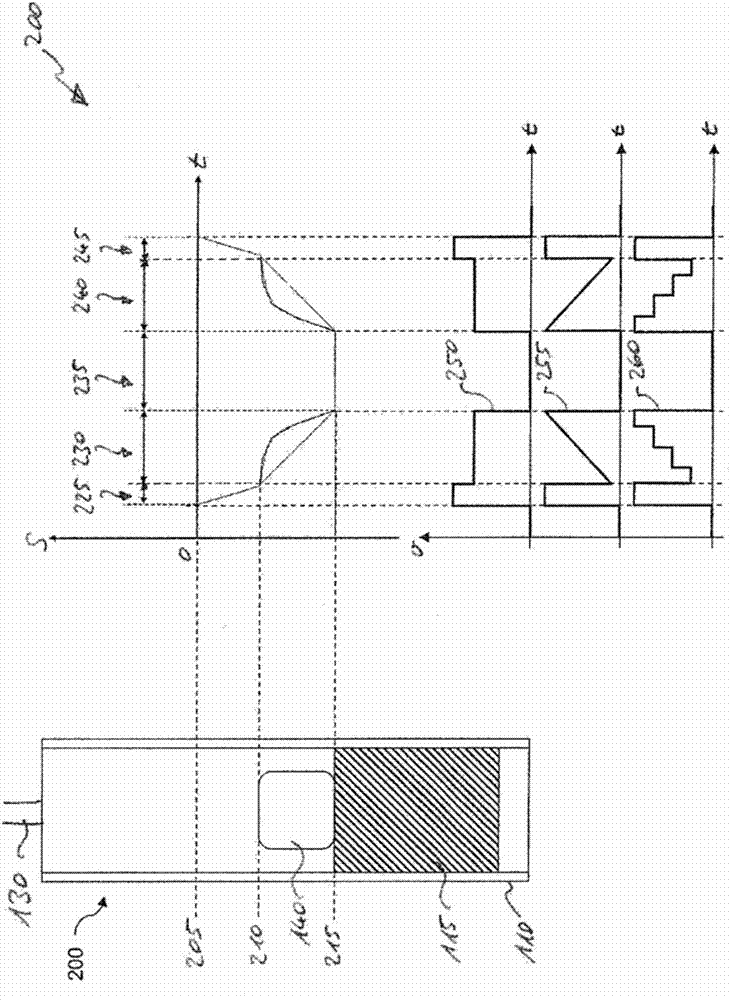

[0022] figure 1 An actuation system 100 for hydraulically actuating a clutch 105 is shown. The clutch 105 is provided for controlled closing or breaking of a force line in a drive train, in particular of a motor vehicle. In a preferred embodiment, a plurality of clutches 105 are provided in the drive train, of which at most one of the clutches is fully engaged at any one time.

[0023] The actuation system 100 comprises: a master cylinder 110 in which a master piston 115 is housed; a slave cylinder 120 in which a slave piston 125 is housed; for fluidly connecting the cylinders 110 and 120 and a reservoir 135 which is fluidly connected to the master cylinder 110 in relation to the position of the master piston 115 by means of a connection opening 140 in the master cylinder 110 . Hydraulic fluid 145 is present in reservoir 135 , master cylinder 110 , pressure line 130 and slave cylinder 120 . The reservoir 135 is pressure-tightly closed relative to the surrounding environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com