Azimuth device applicable to vehicular photoelectric turntable

A photoelectric turntable and azimuth technology, applied in non-electric variable control, position/direction control, instruments, etc., can solve the problems of larger device volume, larger size, and unrealized independent configuration of the rotary shaft system, etc., to achieve strong scalability , Improve the mechanical properties, improve the effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

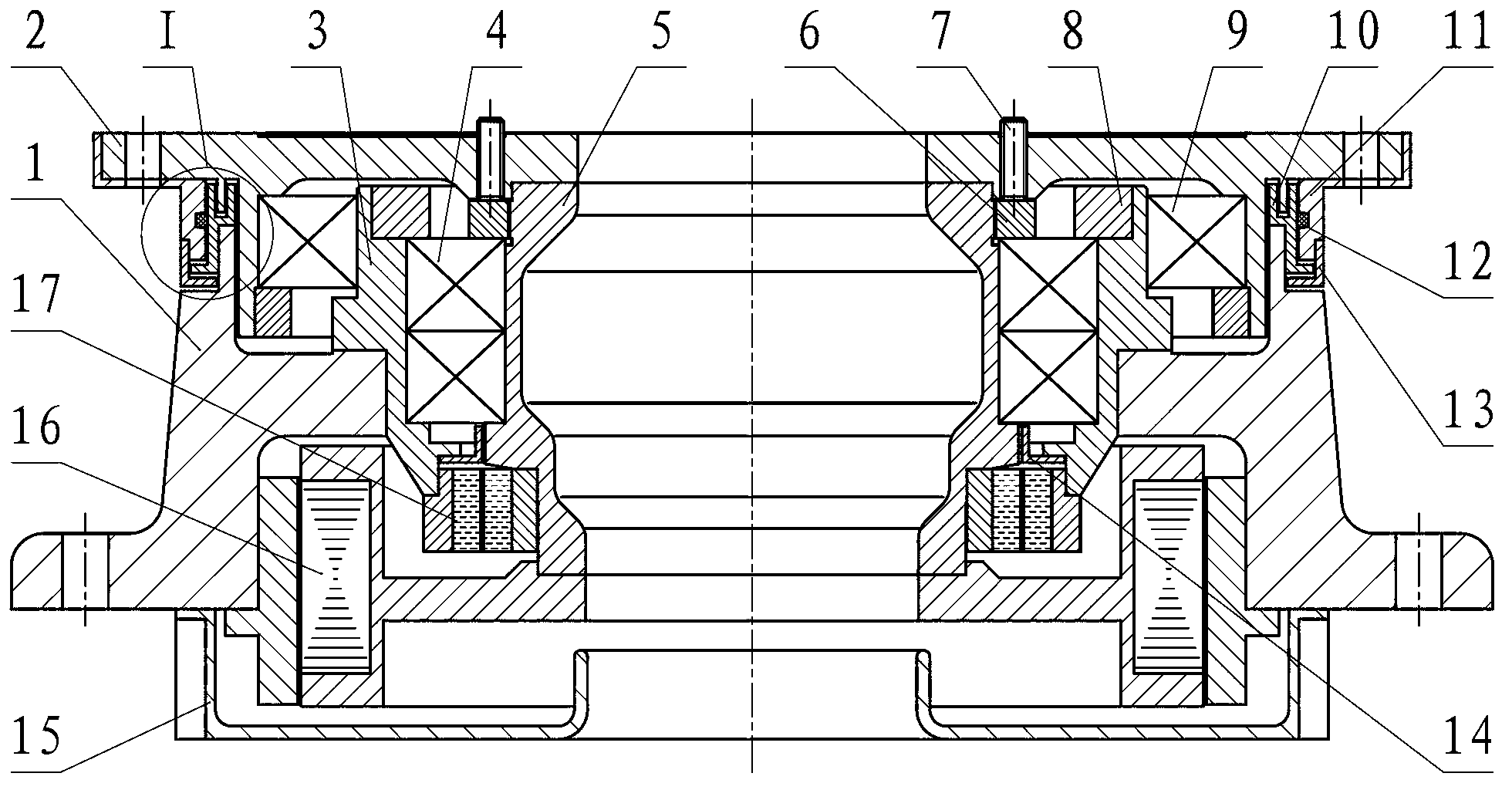

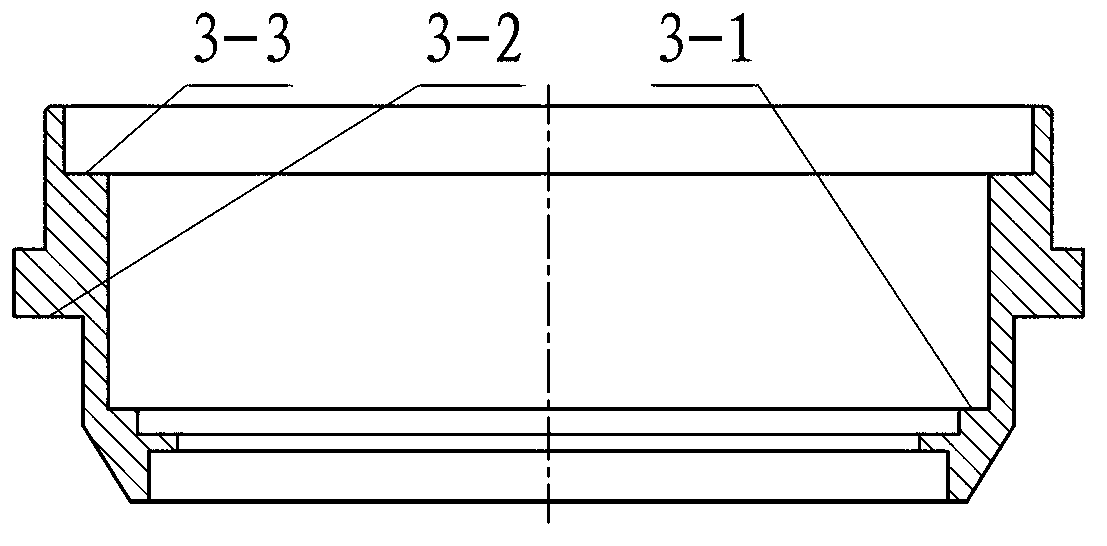

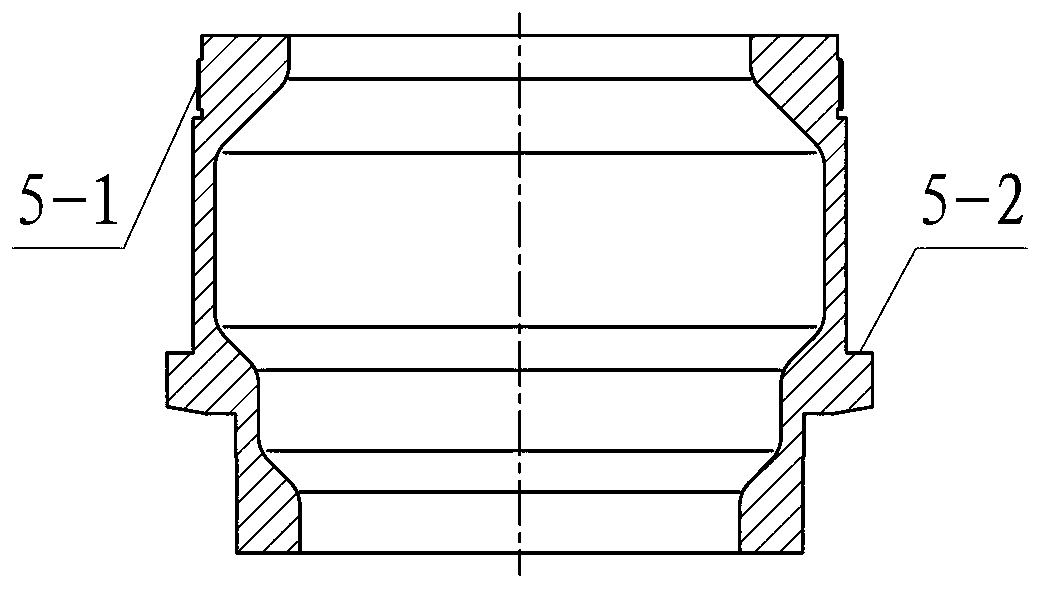

[0024] as figure 1 As shown, the azimuth device provided by the preferred embodiment of the present invention includes a rotary shaft system including an azimuth static shaft 3, an azimuth dynamic shaft 5, an azimuth adapter plate 2, a first bearing 4 and a second bearing 9, an azimuth housing 1, and a torque Motor 16, resolver 17 and azimuth bottom cover 15. The azimuth static shaft 3, the azimuth dynamic shaft 5, the azimuth adapter plate 2, the azimuth housing 1 and the azimuth bottom cover 15 all have a central through hole, and the central through hole is used to pass through the cables or install the signal at the upper and lower ends of the azimuth device. Conductive slip ring. Azimuth static axis 3 (see figure 2 ) is provided with an inner shaft shoulder 3-1 and an inner stepped surface 3-3 inside, and a ring-shaped outer boss 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com