Process for manufacturing magnesium alloy wheel and process for manufacturing wheel rim of magnesium alloy wheel

A manufacturing process, magnesium alloy technology, applied in the field of magnesium alloy wheel manufacturing process and magnesium alloy wheel rim manufacturing process, can solve the problems of easy brittle cracking, difficult stamping, etc., and achieve extremely brittle cracking, reduced stiffness, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

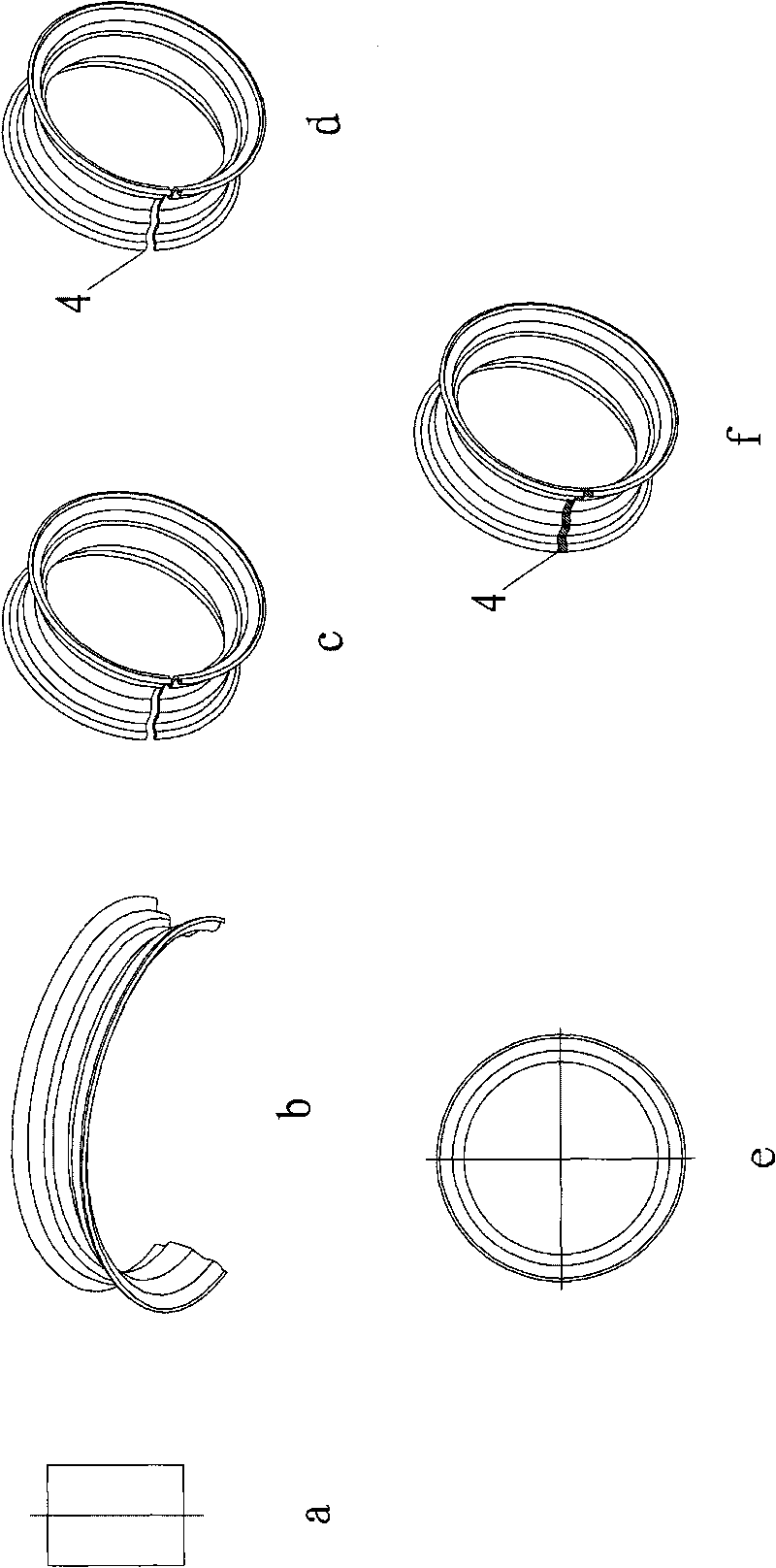

[0028] The wheel rim manufacturing process of the present invention mainly includes: a hot extrusion step, a rounding step and a pore processing step.

[0029] In the hot extrusion step, the magnesium alloy bar is first cut off to a fixed length, referring to figure 2 a. Then in a set of hot extrusion dies (section forming device), the magnesium alloy bar is extruded into a rim semi-finished product. Specifically, the magnesium alloy bar is hot extruded into a profile with a predetermined section, and then in a longitudinal forming device such as Formed on the arc track as figure 2 The large half of the elliptical rim shown in b, the elliptical rim here mainly refers to a shape close to an ellipse or an elliptical rim, for example, figure 2 The two ends of the rim semi-finished product shown in b are rolled on a small circular track, and the middle is rolled on a large circular track, or the rim semi-finished product is directly bent on an elliptical track. The aforement...

no. 2 example

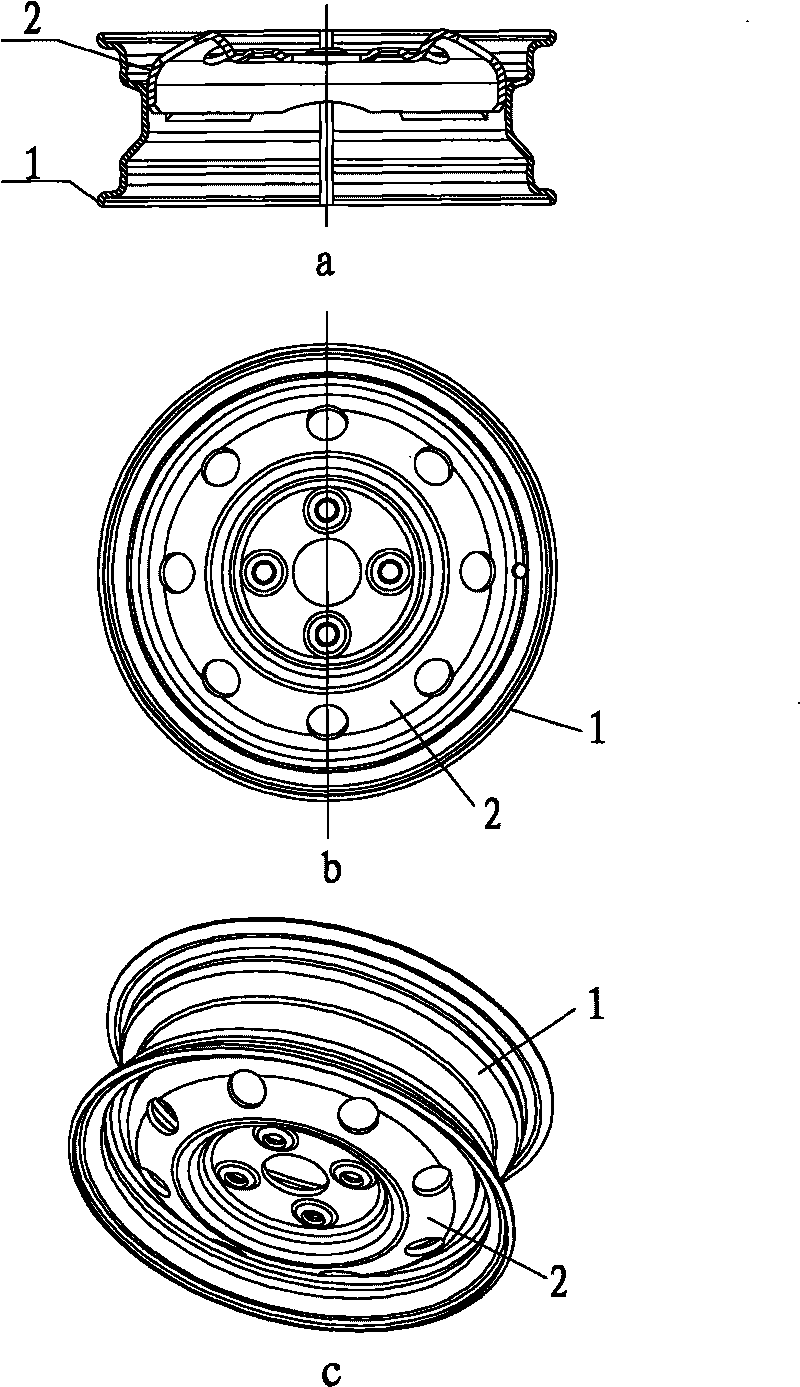

[0033] The magnesium alloy wheel manufacturing process of the present invention mainly includes a wheel rim manufacturing process, a wheel spoke manufacturing process and a combined welding process.

[0034] The rim manufacturing process can be implemented with reference to the aforementioned first embodiment.

[0035] The spoke manufacturing process mainly includes a plate blanking step, a hot stretch forming step and a hot stamping step. The steps of sheet blanking are as follows: image 3 As shown, heat the plate to 280°C-350°C, and then punch out the circular plate and the center hole on the plate. The thermo-stretch forming step includes two thermo-stretch steps in this embodiment, respectively as Figure 4 with Figure 5 As shown, of course, different heat-stretching steps can be selected for different spoke shapes. The heat-stretching step is, for example, heating and stretching on a 200-ton double-action press, and the stretching temperature is between 280°C and 350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com