Dot bubble repair device of touch screen

A touch screen, point-like technology, applied in the touch screen field, can solve the problems of untimely customer delivery, company cost waste, yield loss, etc., and achieve the effect of repairing quality assurance, light weight, and low material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

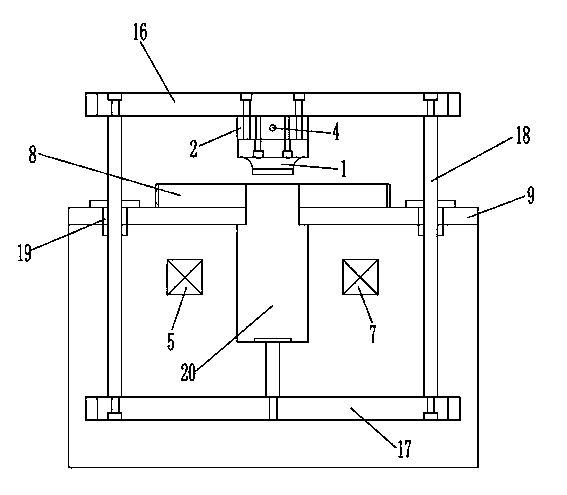

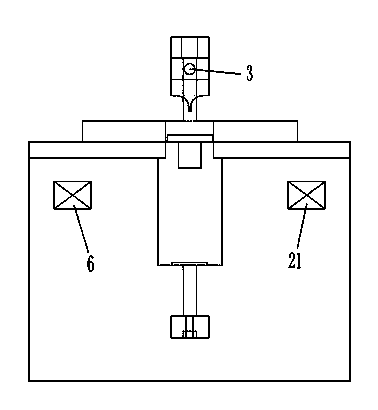

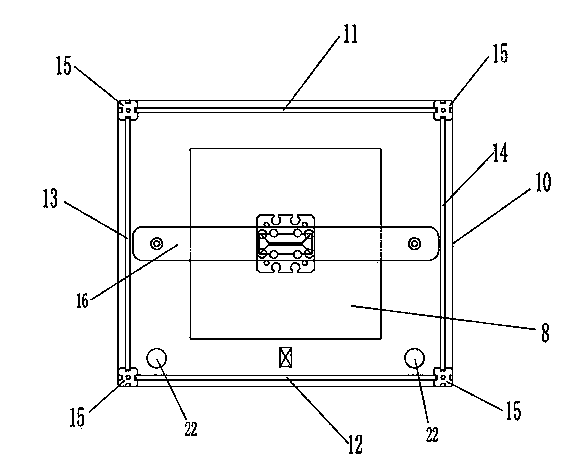

[0025] Figure 1 to Figure 5 The device for repairing point-shaped air bubbles on the touch screen includes a moving bracket, a body, an indenter 1 and an indenter control part. The moving bracket is connected to the body, and the moving bracket and the body move up and down relatively. The head 1 is fixed on the moving support and moves up and down following the moving support. A heating device is fixed between the pressing head 1 and the moving support. The cross section of the pressing head 1 is V-shaped, and the longitudinal section is U-shaped. It is made of titanium alloy The heating device includes a heating block 2 and a heating rod 3, the heating rod 3 is placed in the heating block 2, and the pressure head control part includes a temperature sensor 4, a temperature controller 5 for controlling the heating temperature of the heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com