Carbon fiber yarn fiber-stretching mechanism

A carbon fiber and yarn technology, used in textiles and papermaking, knitting, warp knitting and other directions, can solve the problems of bound carbon fiber yarn application, poor laying performance, and the quality of subsequent parts cannot be well guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

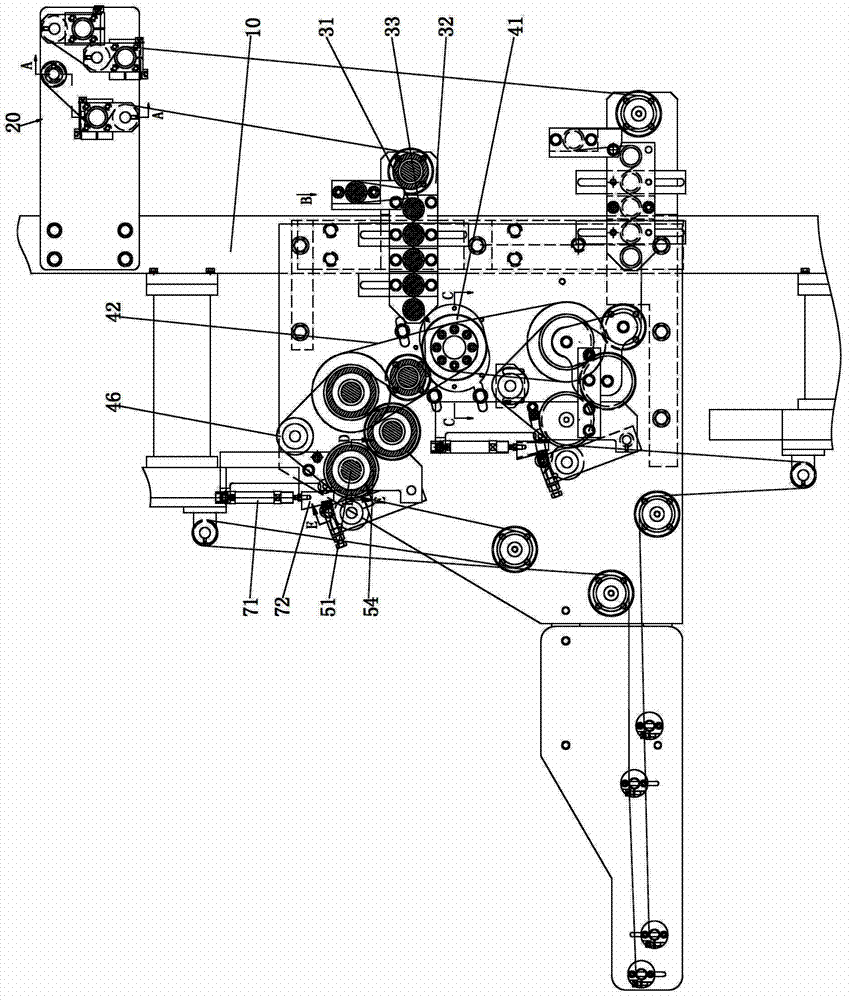

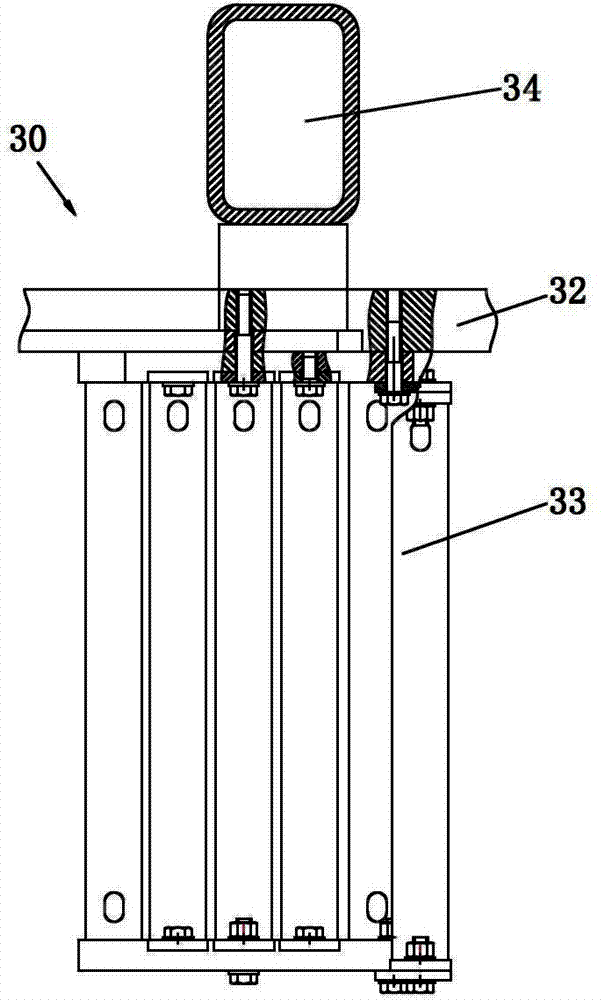

[0035] refer to Figure 1 to Figure 6 , the carbon fiber yarn spreading mechanism in the present invention includes a support 10, a wire device 20, a heating spreading device 30, a synchronous driving device 40, a roller spreading device 50, a tension balance spreading device 60 and a thrust device, respectively below The structure of each part is explained in detail:

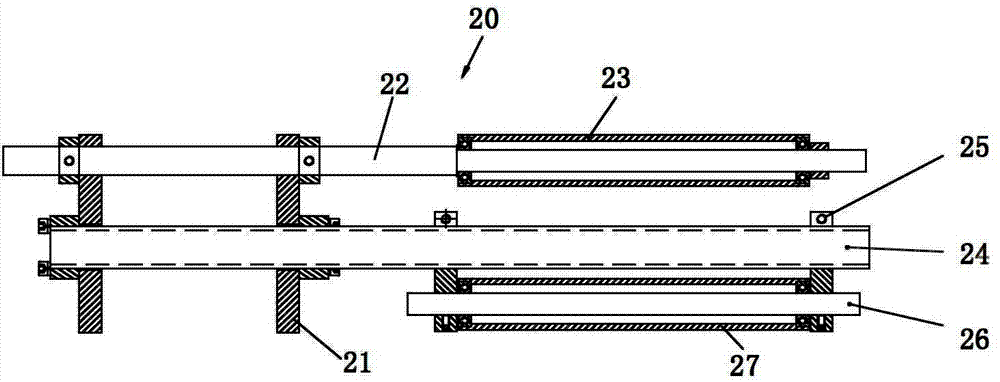

[0036] refer to figure 1 and figure 2 , the wire guide device 20 is fixed on the upper part of the bracket 10, and the wire guide device guides the input carbon fiber yarn and exerts a pulling force. The guide wire device includes a mounting plate 21 , an intermediate roller shaft 22 , a first guide roller 23 , a yarn passing shaft 24 , a splint 25 , a shaft 26 and a second guide roller 27 . Mounting plate 21 is used to be fixed on the support 10, and one end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com