Multiple-disc combined type great-moment brake

A large torque and brake technology, applied in the braking field of heavy lifting machinery, can solve the problems of inconvenient maintenance, low transmission efficiency and complicated transmission, reduce size and overall weight, increase stability and safety, and install The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in more detail by the following examples and accompanying drawings, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

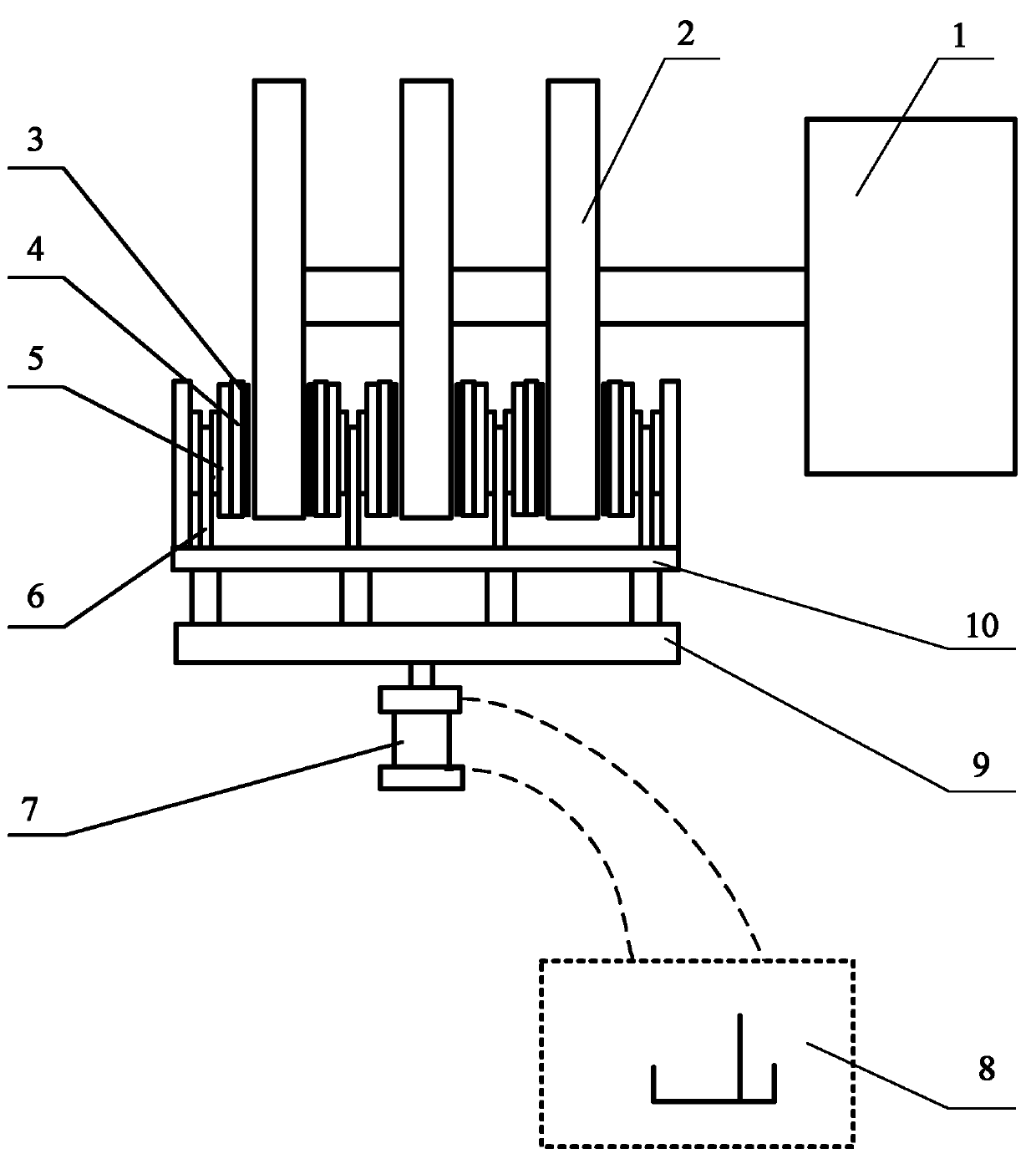

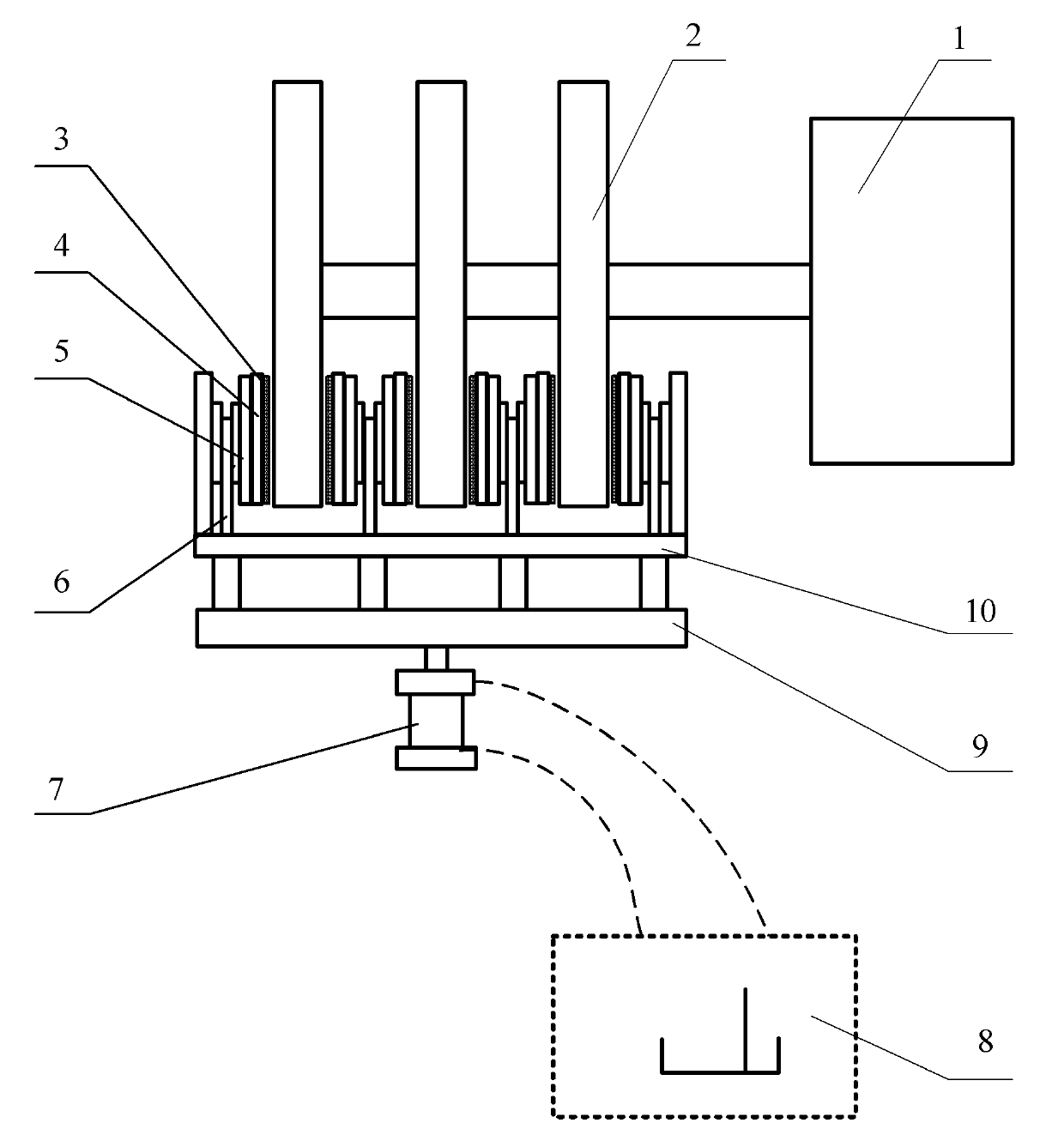

[0011] Such as figure 1 As shown, this example includes a hydraulic station and an execution unit. The execution unit includes a brake disc 2 , a brake pad 3 , a pressure plate 4 , an elastic pressure plate 5 , a wedge-shaped thrust block 6 , a thrust plate 9 and a bracket 10 .

[0012] In actual working conditions, a steel rope for hanging heavy objects is wound on the reel 1, and the reel 1 is coaxially connected with the brake discs 2, and the brake discs 2 are arranged side by side on the shaft. The number of brake discs 2 is determined according to the braking torque, the friction force between the brake pads 3 and the brake disc 2, and the mechanical safety performance. In this example, three brake discs are used.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com