Atomization preparing apparatus and method for wax emulsion

A technology of paraffin emulsion and preparation device, which is applied in the direction of physical wax treatment, etc., can solve the problems of large paraffin emulsion, poor dispersion uniformity and poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

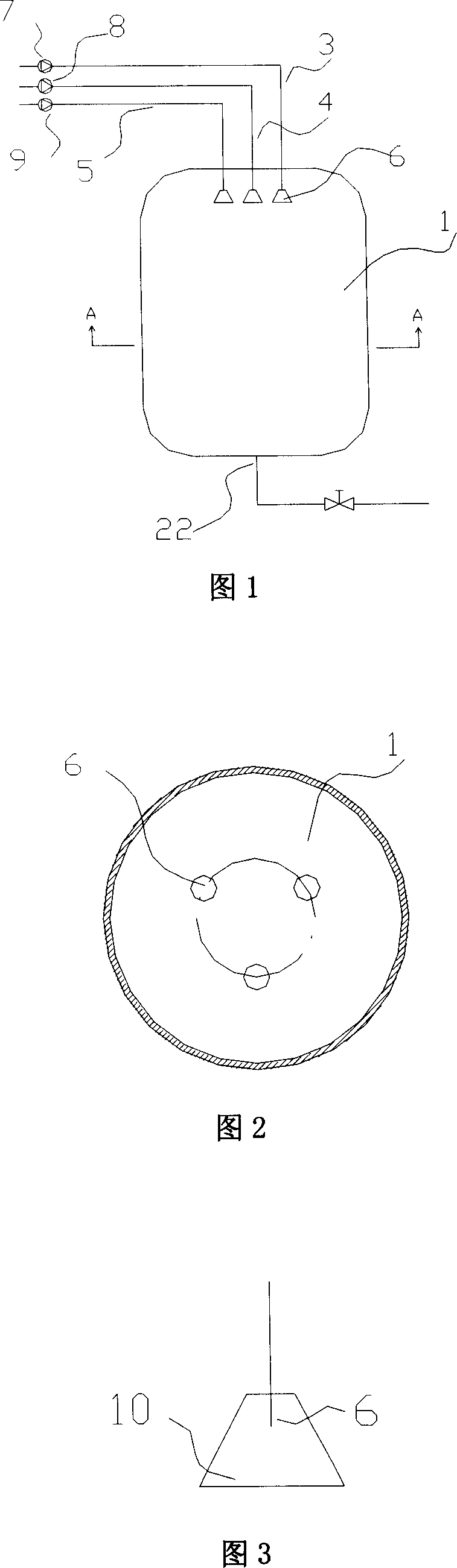

[0022] As shown in Fig. 1 to Fig. 3, a kind of atomization preparation device of paraffin wax emulsion comprises reaction vessel 1, and reaction vessel 1 is provided with outlet 3, the front end of hot water pipe 3, main material pipe 4, auxiliary material pipe 5 Each has an atomizing nozzle 6, each atomizing nozzle 6 all stretches in the reaction vessel 1, is provided with a baffle plate 10 at the front end of the atomizing nozzle 6 and makes described atomizing nozzle 6 face this baffle plate 10, heat A water pump 7, a main material pump 8 and an auxiliary material pump 9 are respectively arranged on the water pipe 3, the main material pipe 4, and the auxiliary material pipe 5.

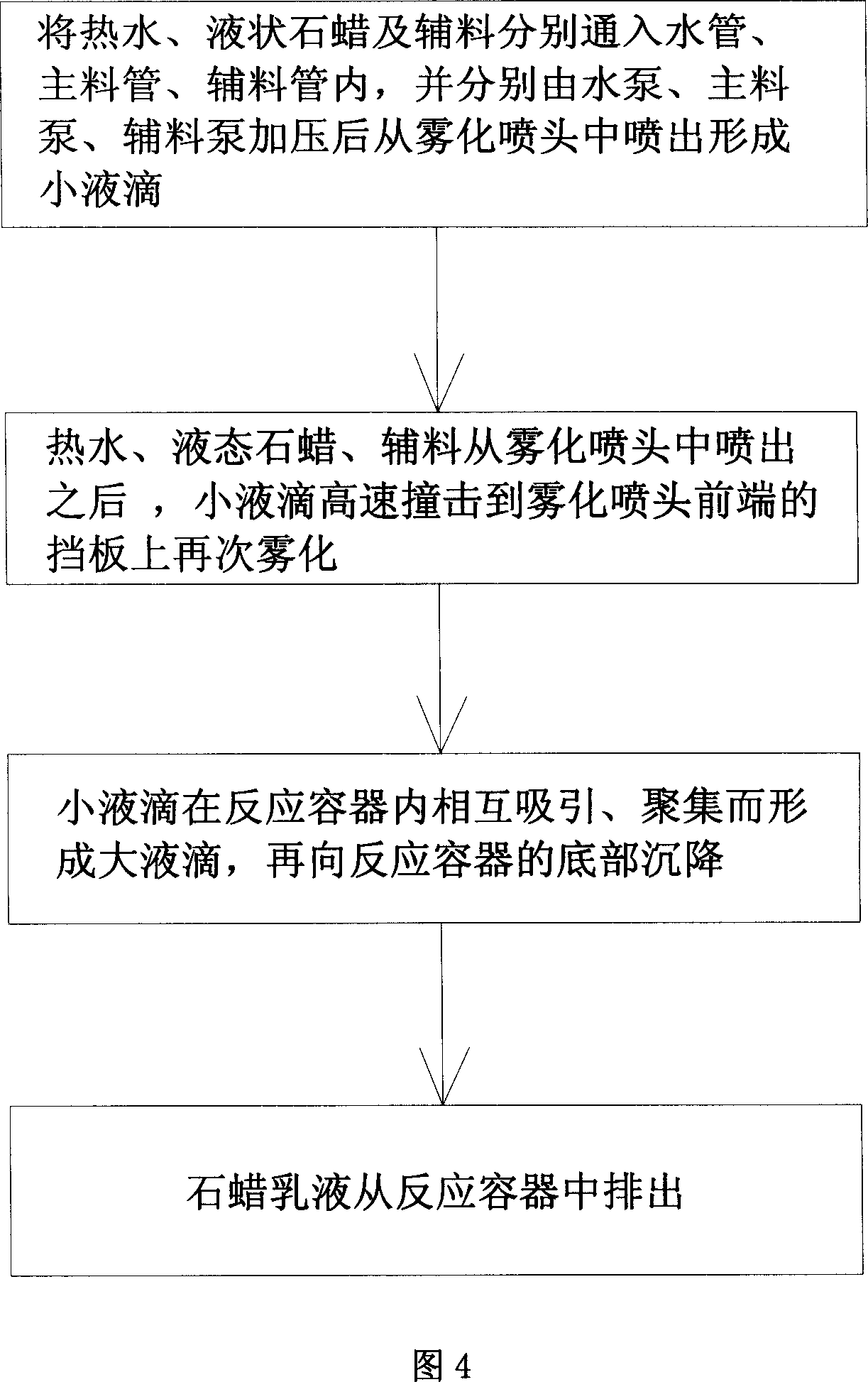

[0023] As shown in Figure 4, a kind of atomization preparation method of paraffin wax emulsion, this method at least comprises the following steps:

[0024] a. Pass hot water, liquid paraffin and auxiliary materials into the water pipe, main material pipe 4, and auxiliary material pipe 5 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com