Symmetric paint spray booth having bidirectional full-flow paint spray purification function

A paint mist purification and paint spray booth technology, applied in the field of paint spray booth, can solve the problems of small surface area of water curtain, low capture rate, inability to achieve full flow atomization, etc., and achieve the effect of improving atomization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

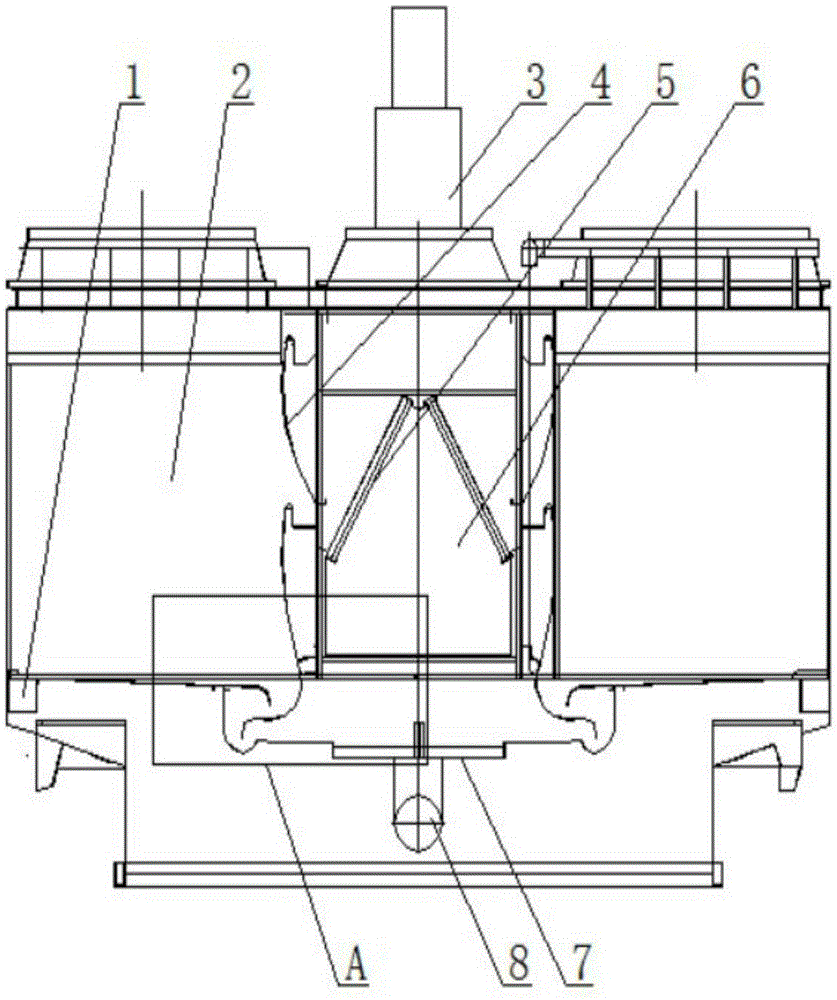

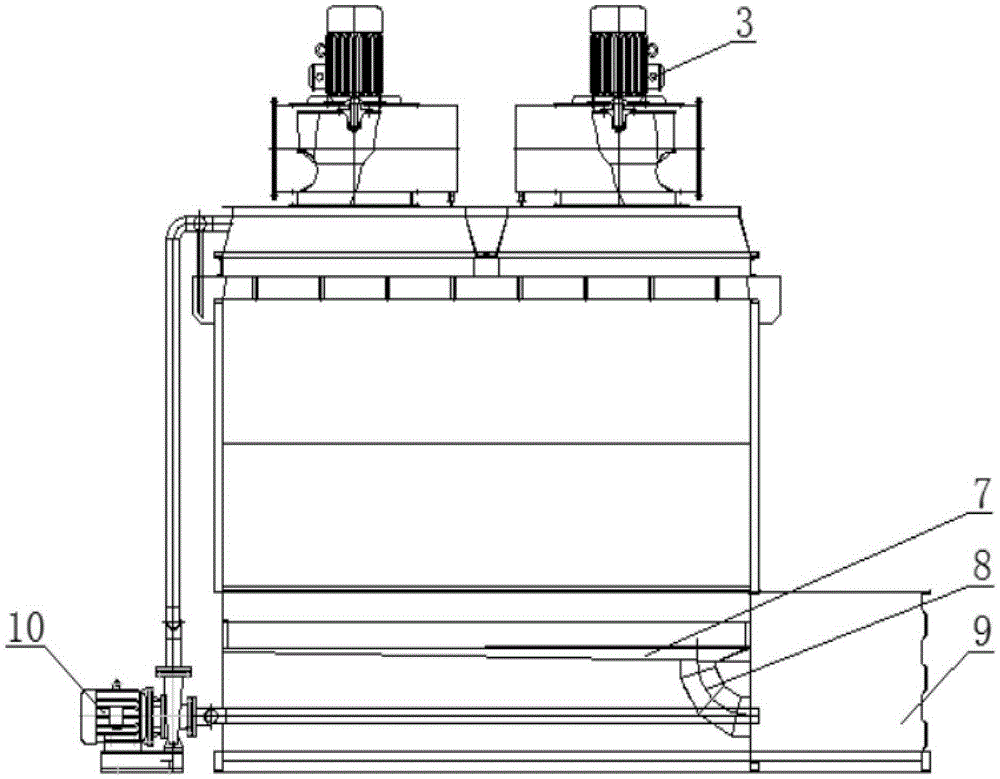

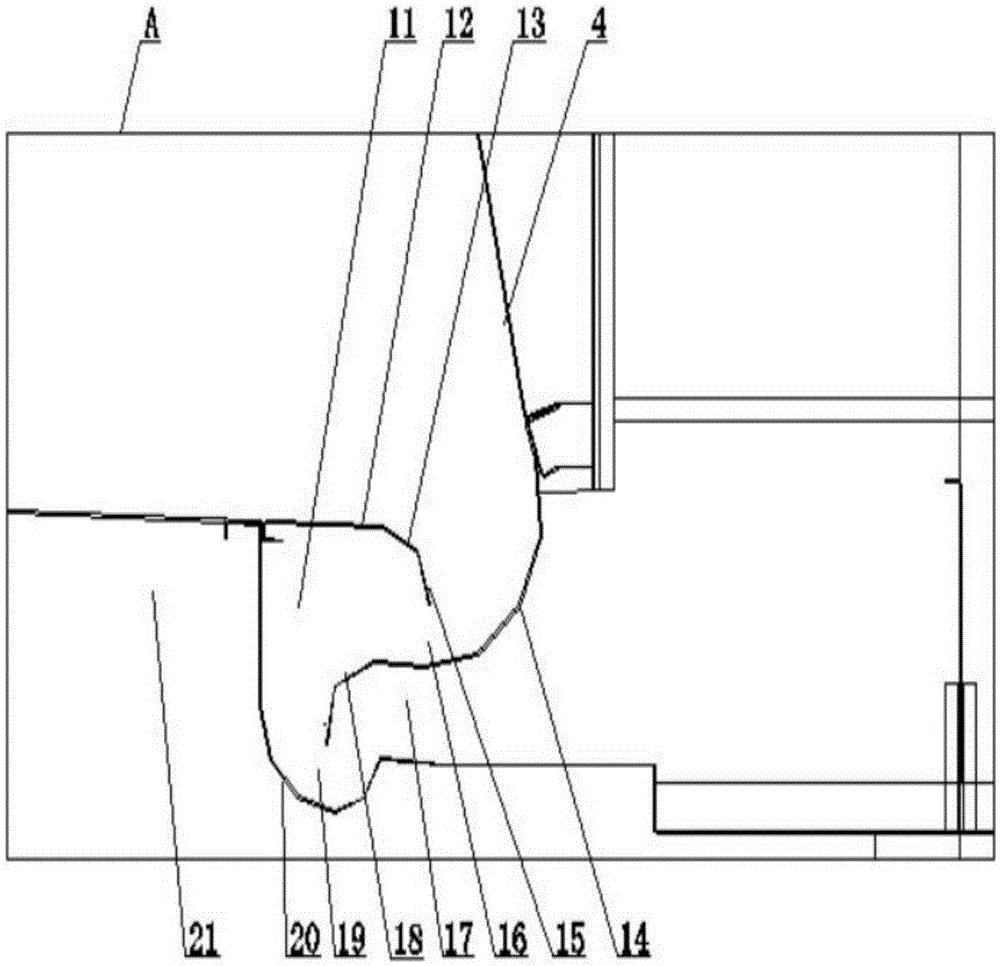

[0024] A symmetrical spray booth with two-way full-flow paint mist purification function, including two spray booths 2 and two gas-liquid separation chambers 6, the two gas-liquid separation chambers are isolated and symmetrically arranged, and the two gas-liquid separation chambers pass through the The respective paint mist capture structures are connected to the respective spray booths, and the inner wall of each spray booth is equipped with a water curtain plate 4, and the bottom surface is provided with a bottom plate flow guide structure 21, and one end of the bottom plate flow guide structure opposite to the lower end of the water curtain plate It is connected with one end of the extended arc deflector of the base plate, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com