High-pressure hydraulic jetting device

A technology of hydraulic jetting and high pressure, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of poor jetting effect and complicated nozzle structure, and achieve the advantages of low friction, flexible rotation and increased jetting range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

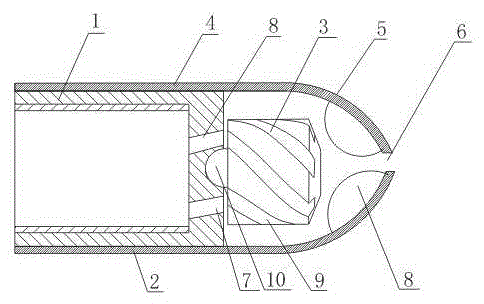

[0018] Such as figure 1 As shown, a high-pressure water jet device includes a connecting body 1, a housing 2, a rotor 3, the connecting body 1 is a cavity structure with an open rear end, and the housing 2 is composed of a hollow cylinder 4 and a hollow hemisphere 5 that are connected, The hollow cylinder 4 is sleeved on the outer wall of the connecting body 1 through a threaded connection, the hollow hemisphere 5 is provided with a water outlet 6 on the top of the sphere; the rotor 3 is rotatably arranged at the bottom of the connecting body 1, and the bottom of the connecting body 1 is evenly provided with impact spray Hole 7; also includes a pressure block 8 evenly arranged on the inner arc surface of the hollow hemisphere 5 around the water outlet 6.

[0019] In this embodiment, the high-pressure pipeline is fixed to the connecting body 1 through the opening on the rear end of the connecting body 1, and the high-pressure liquid input by the high-pressure pipeline enters the c...

Embodiment 2

[0021] In this embodiment, on the basis of embodiment 1, the pressure block 8 is made of rubber material.

[0022] The pressing block 8 is made of rubber material, which effectively improves the pressing effect.

Embodiment 3

[0024] In this embodiment, on the basis of embodiment 1 or embodiment 2, the impact nozzle hole 7 is arranged obliquely at the bottom of the connecting body 1, and the side wall of the rotor 3 is evenly provided with grooves 9 which rotate in the same direction as The impingement nozzle holes 7 are arranged obliquely in opposite directions.

[0025] The impingement nozzle hole 7 is arranged obliquely and the groove 9 is rotated in the opposite direction to that of the impingement nozzle hole 7, so that the liquid passing through the impingement nozzle hole 7 can generate a circumferential force when the surface of the rotor 3 is impacted, so that the rotor 3 Capable of high-speed rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com