Inner hole dual-fuel supersonic flame spray gun and spray method

A supersonic flame, dual-fuel technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of especially serious oxidation, easy to be oxidized, etc., to reduce the size of the gun body, uniform airflow, good deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

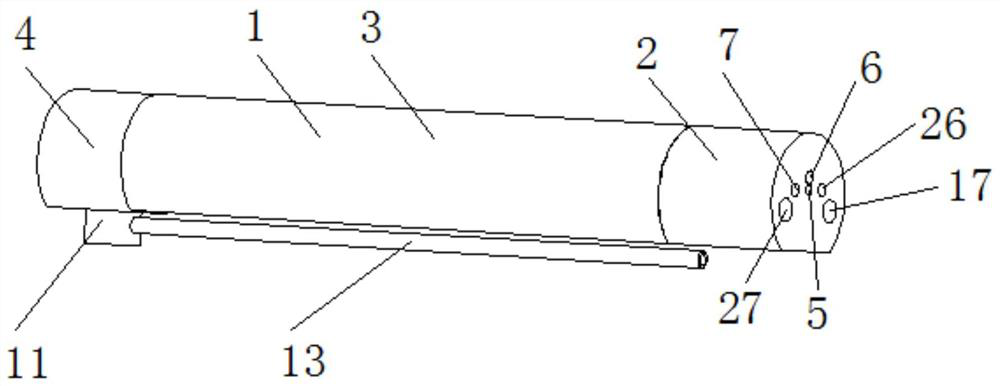

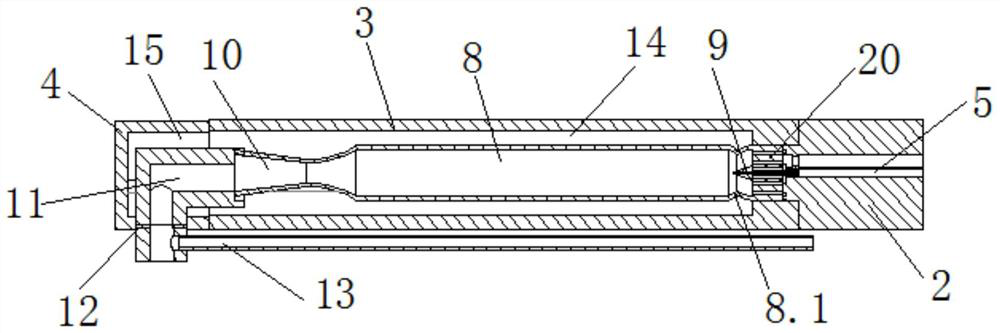

[0040] Embodiment 1: as figure 1 , 2 , 3, 4, 5, and 6, a dual-fuel supersonic flame spray gun with an inner hole includes a gun housing 1, and the gun housing 1 is divided into three sections of front section 2, middle section 3, and rear section 4, and front section 2 is provided with kerosene Channel 5, several gas channels 6 and several oxygen channels 7, the gas channels 6 are preferably hydrogen channels. The middle section 3 is provided with a combustion chamber 8, the outlet end of the kerosene channel 5 is provided with a kerosene nozzle 9 extending into the combustion chamber 8, and the combustion chamber 8 is provided with a necking section 8.1 at the outlet of the kerosene nozzle. The gas passage 6, the oxygen passage 7 communicate with the combustion chamber 8 of the middle section 3, the outlet of the combustion chamber 8 is provided with a Laval nozzle 10, and the rear section 4 is provided with an elbow-shaped nozzle 11 communicating with the Laval nozzle 10, a...

Embodiment 2

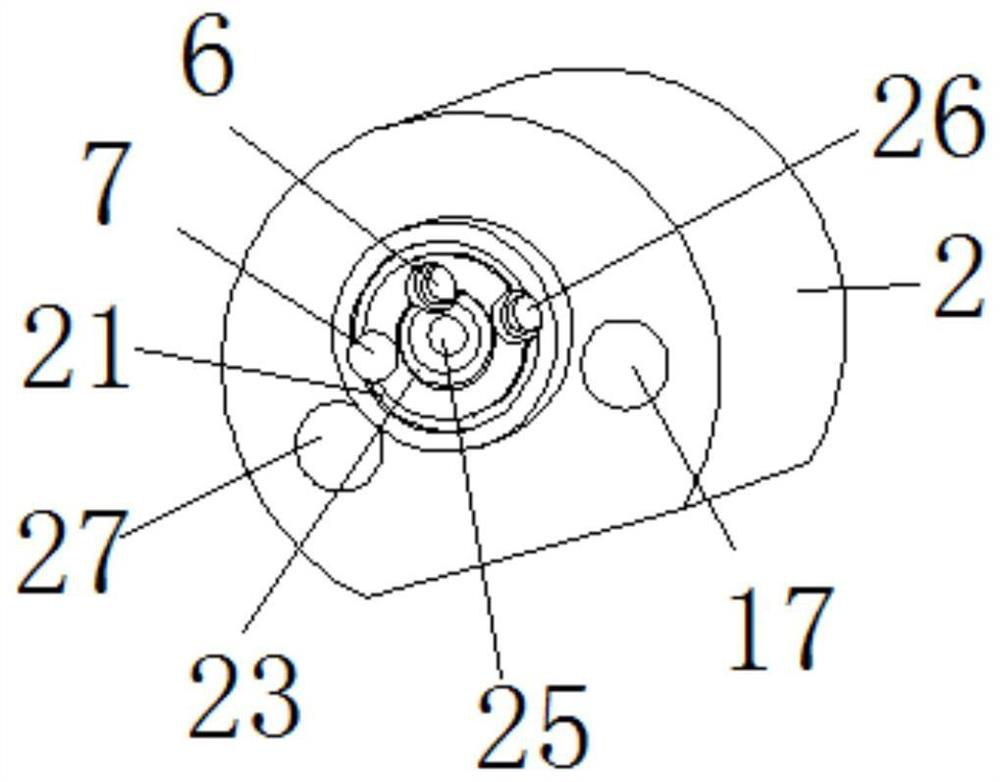

[0043] Embodiment 2: as Figure 7 As shown, a dual-fuel supersonic flame spray gun with an inner hole includes a gun casing 1, and the gun casing 1 is divided into three sections: front section 2, middle section 3, and rear section 4. The front section 2 is provided with a gas channel 6, and the front section is provided with a mixing The gas ring 20 is provided with an oxygen passage 7 on the gas mixing ring, and is provided with annularly distributed gas through holes 22 on the gas mixing ring ′ , there is an annular gas cavity 23 between the gas mixing ring 20 and the front end 2 ′ , there is a kerosene nozzle 9 in the gas mixing ring 20, a kerosene channel 5 is arranged on the kerosene nozzle 9, and an annular oxygen chamber 21 is arranged between the gas mixing ring 20 and the kerosene nozzle 9 ′ .

[0044] The middle section 3 is provided with a combustion chamber 8, the front end of the combustion chamber 8 has a gas pre-mixing chamber 8.2, the combustion chamber 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com