Fuel feeding device of engine

A fuel supply device, engine technology, applied in the direction of fuel injection device, engine components, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

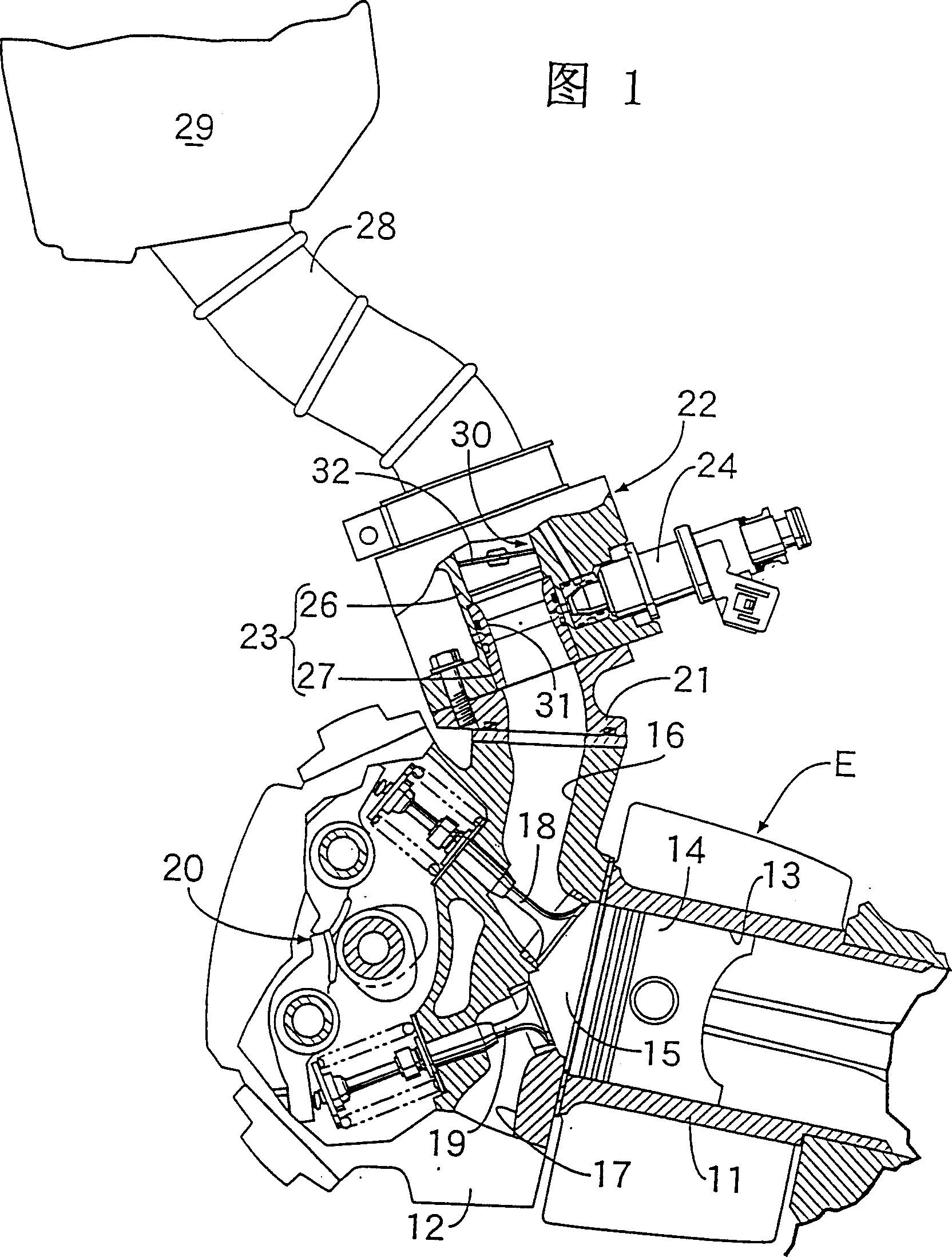

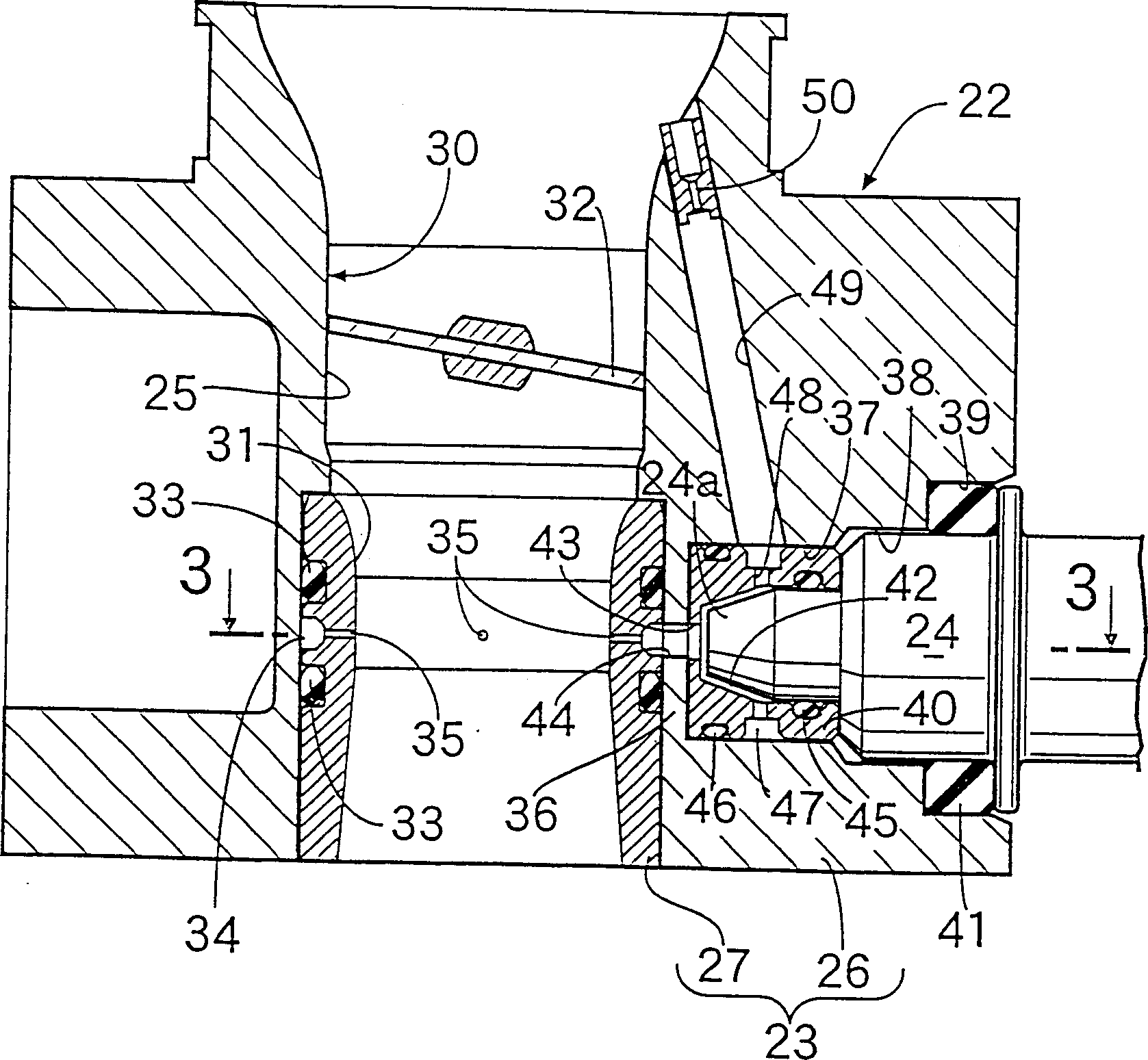

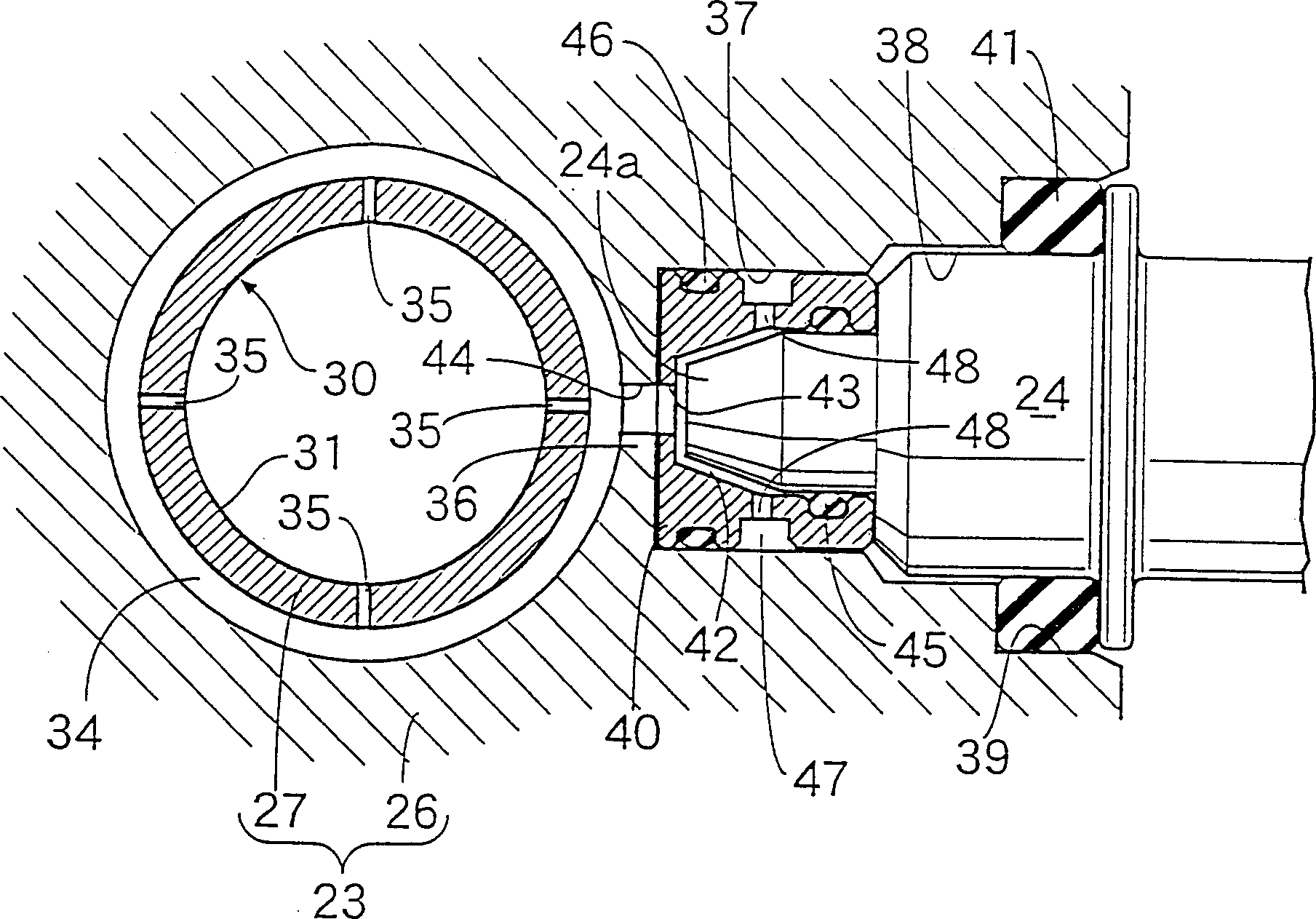

[0020] Next, embodiments of the present invention will be described based on the embodiments of the present invention shown in the drawings.

[0021] Figure 1~ Image 6 Showing the first embodiment of the present invention, Fig. 1 is a cutaway side view showing the intake system of the invention, figure 2 is the enlarged longitudinal section view of the intake channel forming body, image 3 for figure 2 A 3-3 line cross-sectional view of the, Figure 4 is a graph showing the relationship between fuel supply pressure and exhaust performance, Figure 5 is a graph showing the relationship between fuel injection timing and exhaust performance, Image 6 is a graph showing the relationship between net mean effective pressure and exhaust performance.

[0022] In FIG. 1 , the engine E has a cylinder block 11 and a cylinder head 12 joined to the cylinder block 11 , and a combustion chamber 15 is formed between the piston 14 and the cylinder head 12 , and the piston 14 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com