Cooling device and cooling method for reinforced polypropylene material production

A polypropylene material and cooling device technology, applied in the field of cooling equipment, can solve problems such as low work efficiency, long cooling time, and reduced performance, so as to achieve the effects of not being easily damaged, improving production efficiency and performance, and reducing the use of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

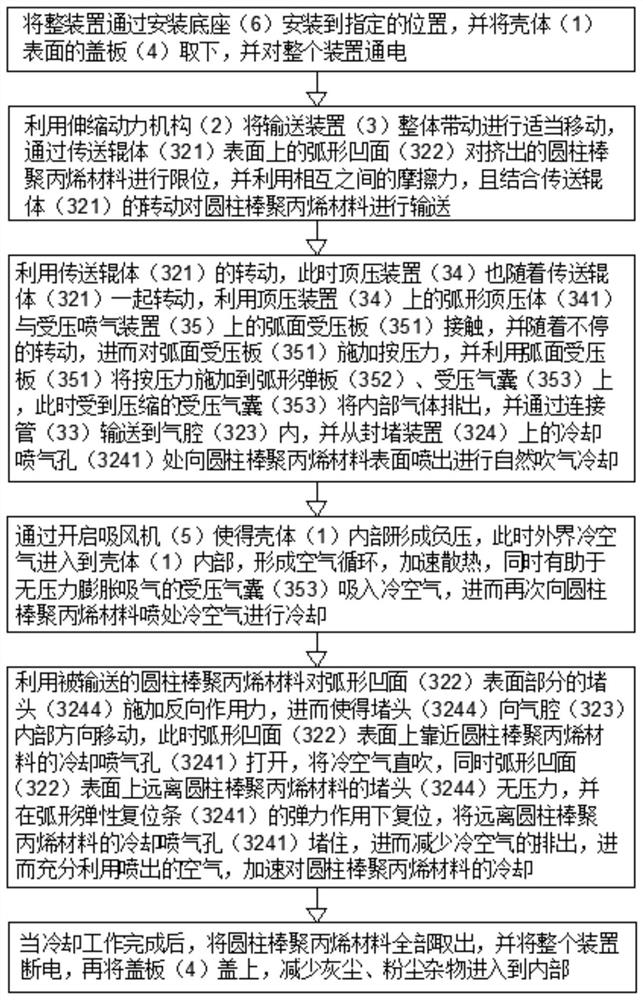

Image

Examples

Embodiment 1

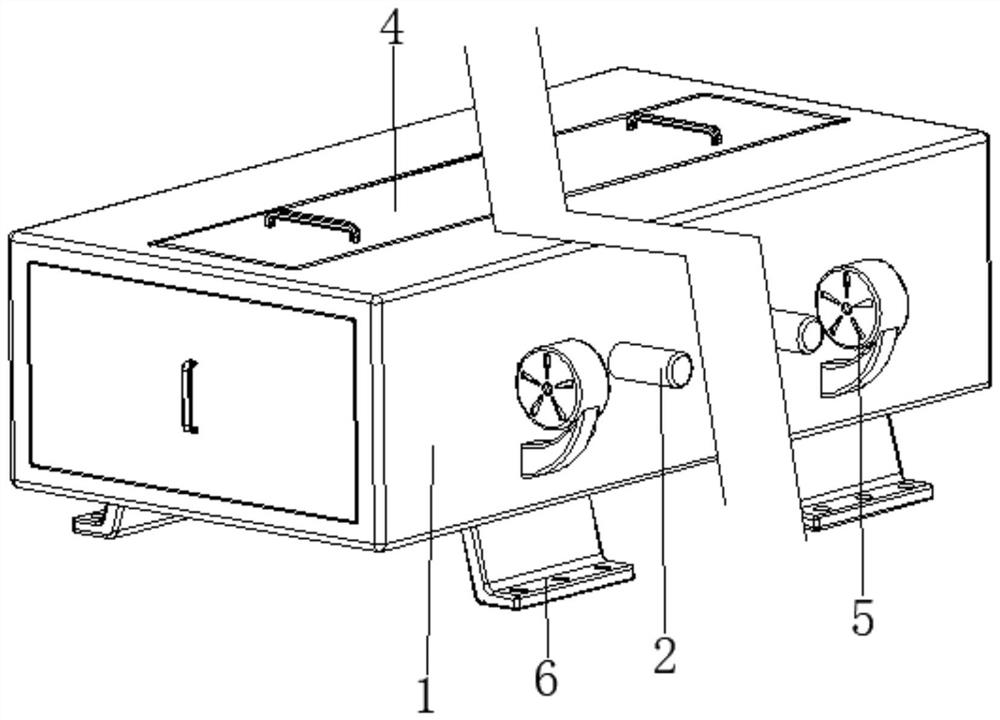

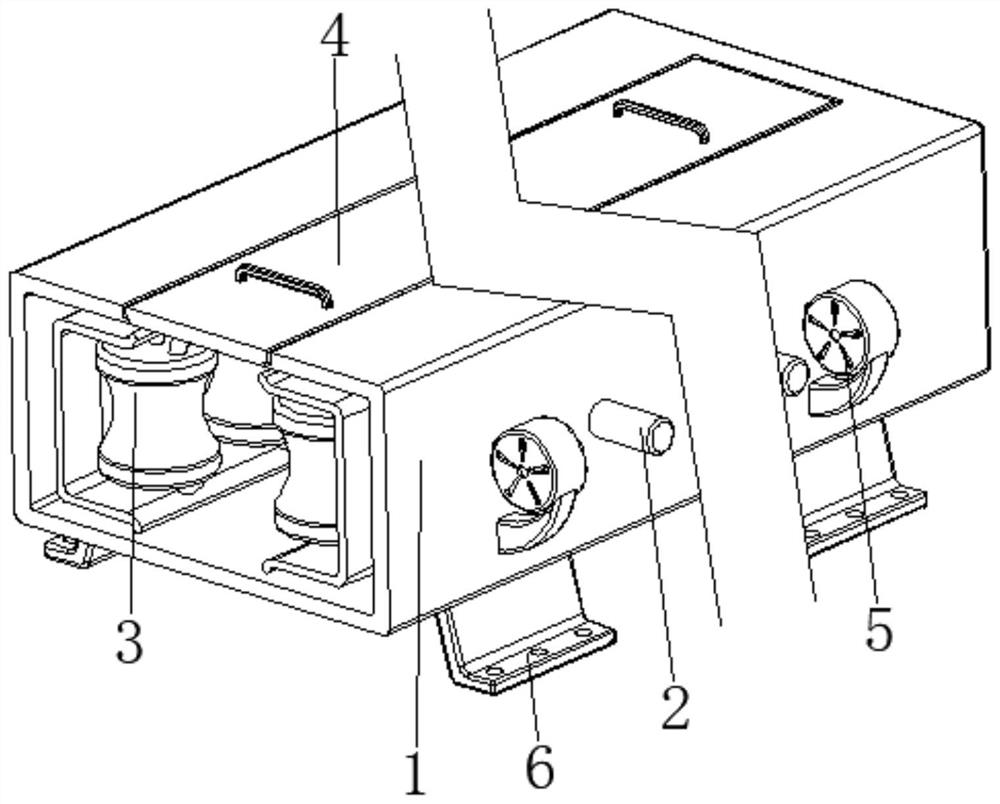

[0039] see Figure 1-Figure 8 , the present invention provides a technical solution: a cooling device for reinforced polypropylene material production, comprising a casing 1, a telescopic power mechanism 2, and a conveying device 3, the surface of the telescopic power mechanism 2 is fixedly connected with the surface of the casing 1, and the conveying The device 3 is arranged inside the housing 1 and is close to the position of the telescopic power mechanism 2;

[0040] The conveying device 3 is provided with a U-shaped frame 31, a conveying cooling device 32, a connecting pipe 33, a pressing device 34, and a pressurized air jet device 35. The U-shaped frame 31 is arranged inside the casing 1, and the opening of the U-shaped frame 31 faces a side, the surface side of the U-shaped frame 31 is fixedly connected with the working end of the telescopic power mechanism 2, the transmission cooling device 32 is arranged inside the U-shaped frame 31, the connecting pipe 33 is arranged ...

Embodiment 2

[0046]The top pressing device 34 is provided with an arc-shaped pressing body 341, a supporting reinforcing rib 342, and a ball 343. One end of the arc-shaped pressing body 341 is fixedly connected with the end of the conveying roller body 321, and the supporting reinforcing rib 342 is fixed on the arc-shaped pressing body 341. Between the surface of the body 341 and the two sides corresponding to the end of the conveying roller body 321 , the balls 343 are rollingly connected to the surface of the arc-shaped pressing body 341 and away from the side of the supporting reinforcing rib 342 .

[0047] The balls 343 are evenly distributed on the surface of the arc-shaped pressing body 341. The surface of the arc-shaped pressing body 341 and the side away from the support reinforcement rib 342 are provided with rolling grooves that are adapted to the balls 343. The device 3 is driven as a whole to move appropriately, and the extruded cylindrical bar polypropylene material is limited ...

Embodiment 3

[0049] The pressure jet device 35 is provided with an arc pressure plate 351, an arc spring plate 352, and a pressure air bag 353. The surface edge of the arc pressure plate 351 is hinged with the inner wall of the U-shaped frame 31, and the arc spring plate 352 It is fixed between the surface of the arc pressure plate 351 and the two sides corresponding to the inner wall of the U-shaped frame 31, and the pressure airbag 353 is arranged between the surface of the arc pressure plate 351 and the two sides corresponding to the inner wall of the U-shaped frame 31 and Close to the arc-shaped spring plate 352, the air port of the pressure air bag 353 is connected to the end of the connecting pipe 33 away from the conveying roller body 321. When the arc-shaped pressing body 341 exerts a pressing force on the arc-shaped pressure plate 351, it combines with the arc surface. One side of the surface edge of the pressure-receiving plate 351 is hinged with the inner wall of the U-shaped fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com