Paper feed roll

A technology of paper feed rollers and convex parts, which is applied in the field of paper feed rollers and can solve problems such as poor paper conveyance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17、 comparative example 1~4

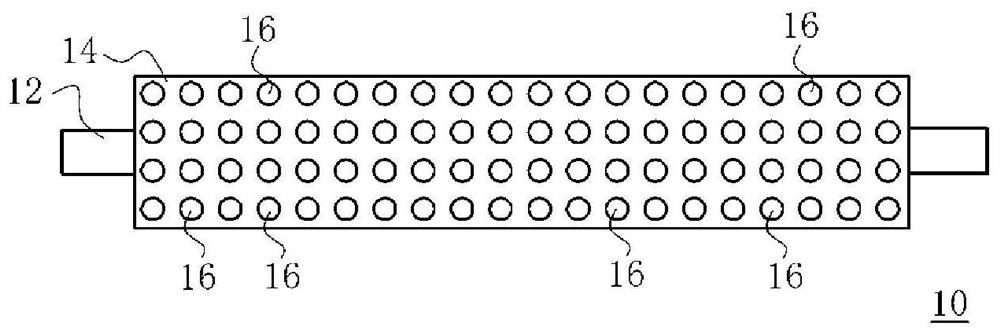

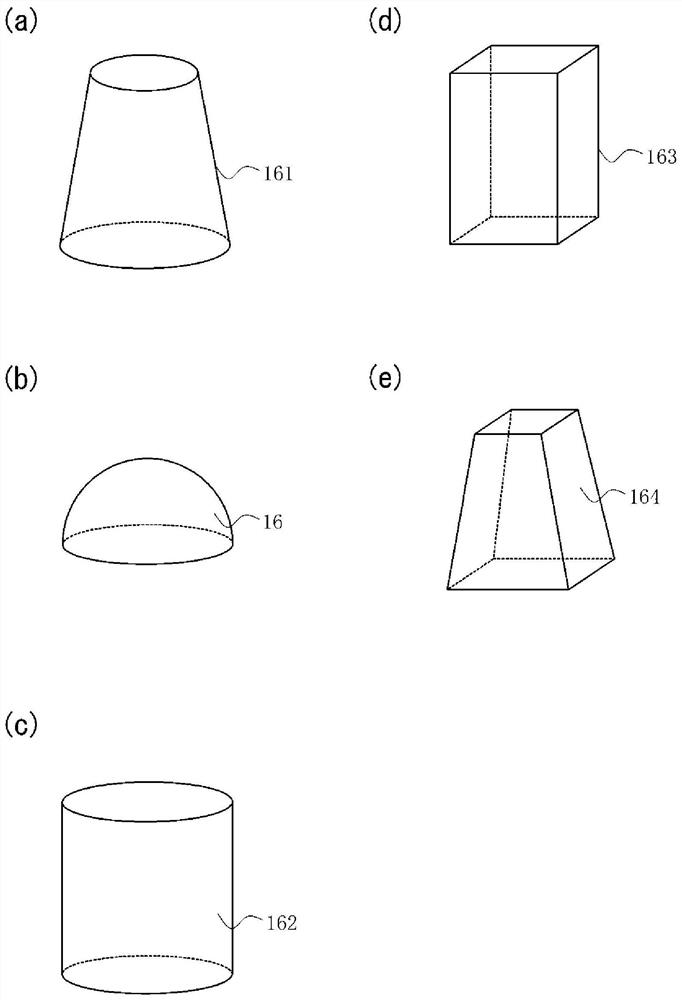

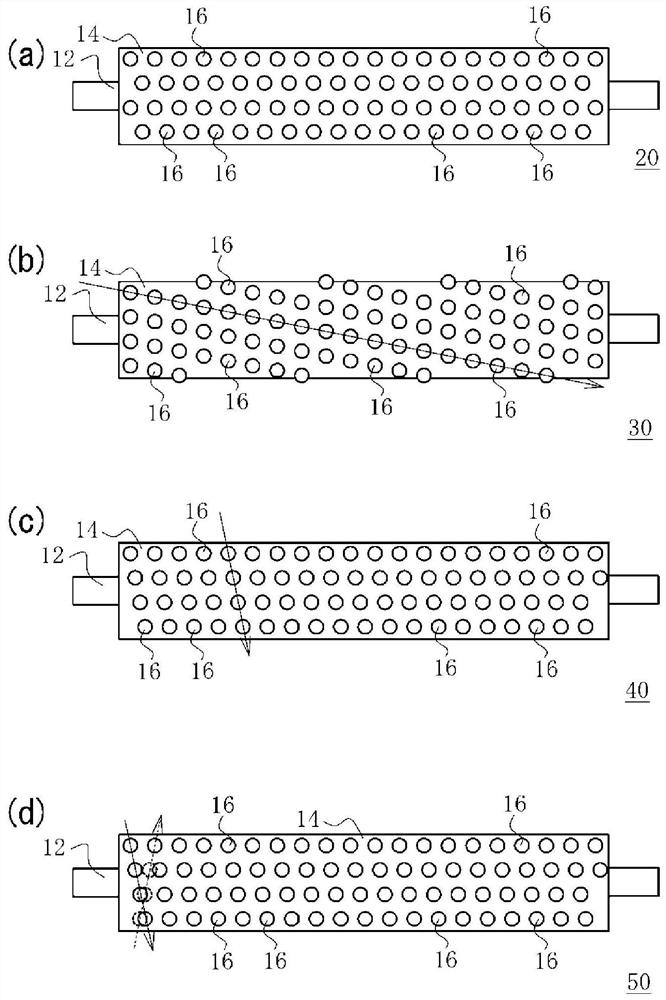

[0053] An elastic body layer (thickness: 3 mm) of a polyurethane rubber composition was formed on the outer periphery of a core material (φ6, made of SUS304) using a cylindrical molding die having a plurality of predetermined recesses on the inner peripheral surface. Thus, a paper feed roller having a predetermined plurality of protrusions on the peripheral surface of the elastic layer is obtained. Tables 2 to 4 show the shape of the protrusions, the arrangement of the protrusions, and the height of the protrusions. Table 1 below shows the correspondence relationship between the shape of the convex part and the figure number, and the relationship between the arrangement of the convex part and the figure number. Irregular protrusions were formed using a cylindrical molding die in which electrical discharge machining was performed on the inner peripheral surface. In addition, the corrugated protrusion shape was formed using a cylindrical molding die in which the inner periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com