Nonaqueous electrolyte solution and nonaqueous electrolyte secondary battery using same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of battery capacity reduction, battery material degradation, safety reduction, etc. The effect of excellent gas generation and cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A-1

[0470] Under a dry argon atmosphere, ethylene carbonate (EC) as a cyclic carbonate, dimethyl carbonate (DMC) as a chain carbonate, and ethyl methyl carbonate (EMC) as EC:DMC:EMC=30 : 30:40 volume ratio, add fully dried LiPF so that it becomes 1.0 mol / L 6 (The resulting mixture is referred to as "reference electrolyte"). With respect to the whole reference electrolytic solution, methacrylic anhydride was added so that it might become 0.5 mass %, and vinylene carbonate (VC) would be added so that it might become 1 mass %, and the non-aqueous electrolytic solution was prepared.

Embodiment 1A-2~1A-8

[0471] [Examples 1A-2 to 1A-8, Comparative Examples 1A-1 to 1A-8, Reference Examples 1A-1 to 1A-11]

[0472] A reference electrolyte solution was prepared in the same manner as in Example 1A-1, and the compounds listed in Table 1 below were added in proportion to the entire obtained reference electrolyte solution to prepare each non-aqueous electrolyte solution. Among them, Comparative Example 1A-1 is the reference electrolyte solution itself.

[0473]

[0474] In 98 parts by mass of graphite powder as the negative active material, add 1 part by mass of the aqueous dispersion of carboxymethylcellulose sodium and 1 part by mass of the aqueous dispersion of styrene-butadiene rubber as thickener and binding agent , mixed with a disperser to make a slurry. The obtained slurry was applied to one surface of a copper foil, dried, and pressurized, and the negative electrode was cut into circular shapes with a diameter of 12.5 mm and used. The prepared negative electrode was used a...

Embodiment 2A-1~2A-5、 comparative example 2A-1~2A-7

[0491] [Examples 2A-1 to 2A-5, Comparative Examples 2A-1 to 2A-7, Reference Examples 2A-1 to 2A-6]

[0492] A reference electrolyte solution was prepared in the same manner as in Example 1A-1, and the compounds described in the following Table 2 were added in proportion to the entire obtained reference electrolyte solution to prepare each non-aqueous electrolyte solution, and a coin-type battery was produced. Table 2 shows the results of the initial charge-discharge efficiency (%) obtained by (initial discharge capacity / initial charge capacity)×100. In addition, the examples, comparative examples, and reference examples described in Table 2 all used the same reference electrolyte solution as in Table 1.

[0493] [Table 2]

[0494] Table 2

[0495]

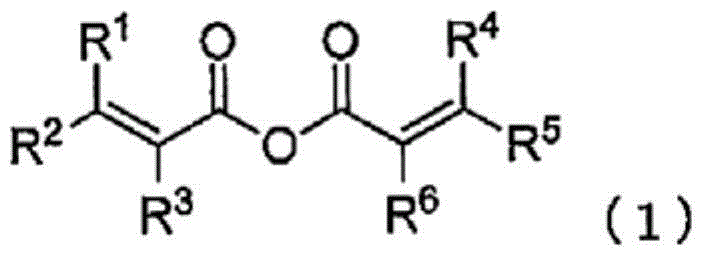

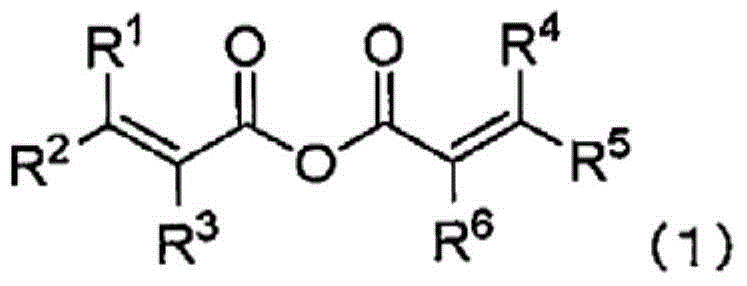

[0496] In Comparative Example 2A-2 using methacrylic anhydride, which is a compound represented by formula (1), the initial charge-discharge efficiency decreased compared with Comparative Example 2A-1 using only the standard ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com