Intelligent preparation method and device of composite peptide for improving sleep quality

A technology for improving sleep quality and intelligent preparation, applied in cleaning methods using tools, devices that make medicines into special physical or ingestible forms, cleaning methods and utensils, etc., can solve poor product quality, low operating efficiency, difficult Powder removal and other issues, to achieve the effect of accelerating filtration efficiency and filtration effect, improving operation efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of intelligent preparation method of the composite peptide for improving sleep quality proposed by the present invention, the preparation method comprises the following steps:

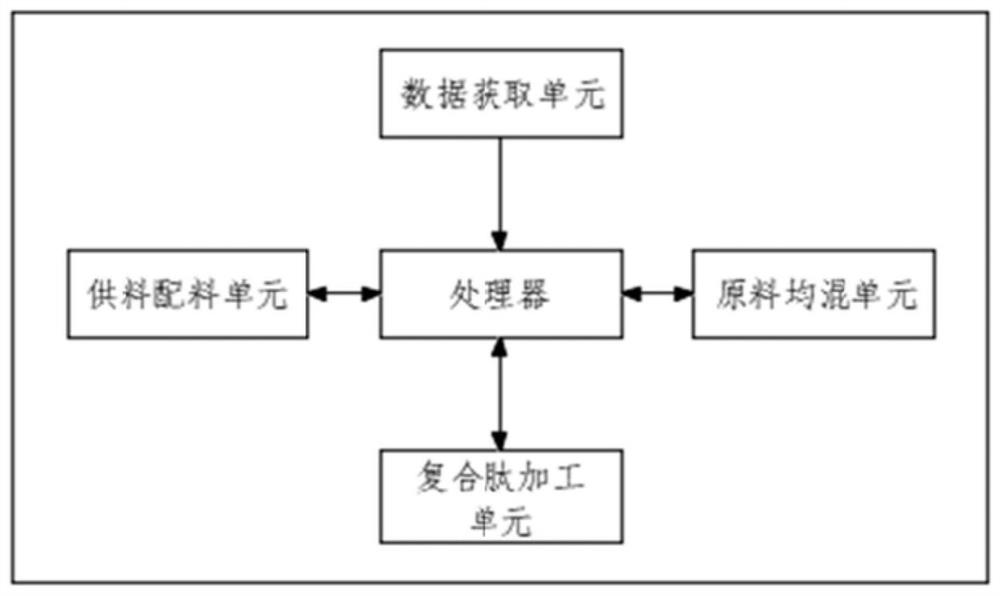

[0051] Step 1. The control panel includes a data acquisition unit and a processor. The processor is connected to the data acquisition unit in communication. The data acquisition unit collects processing information. The processing information includes the formula of the compound peptide product to be processed, the product order number and the processing parameters, and the obtained The collected processing information is sent to the processor;

[0052] Step 2. The processor communicates with the compound peptide processing unit 1, the material supply batching unit 2 and the raw material mixing unit 3. After receiving the processing information, the processor generates a batching signal and sends the batching signal to the feeding batching unit 2; The batching unit 2 includes a plurality ...

Embodiment 2

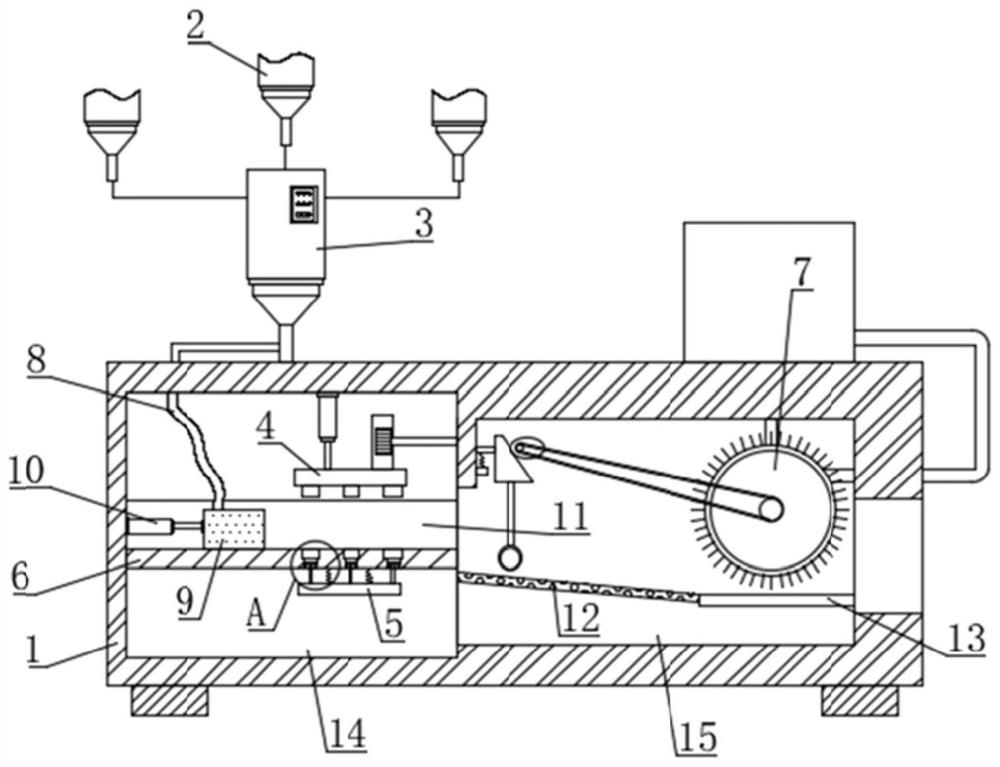

[0057] like Figure 1-6 As shown, the difference between this embodiment and Embodiment 1 is that a processing chamber 14 and a powder cleaning chamber 15 are provided in the compound peptide processing unit 1, and a horizontally arranged processing plate 6 is installed in the processing chamber 14 by bolts, and the processing chamber 14 is provided with feed pushing cylinder 10 and feed box 9, the opening of feed box 9 faces down and presses processing plate 6, and the top of processing plate 6 offers many sets of pressure grooves 61, and the opening of feed box 9 The top is equipped with a feeding pipe 8 communicating with the raw material mixing unit 3; the feeding pipe 8 transports the blended raw materials in the raw material mixing unit 3 to the feeding box 9, starts to feed the pushing cylinder 10, and feeds the pushing cylinder 10 is stretched, so that the feed box 9 is reset after being swept over the top of each group of pressing grooves 61. During the process of pus...

Embodiment 3

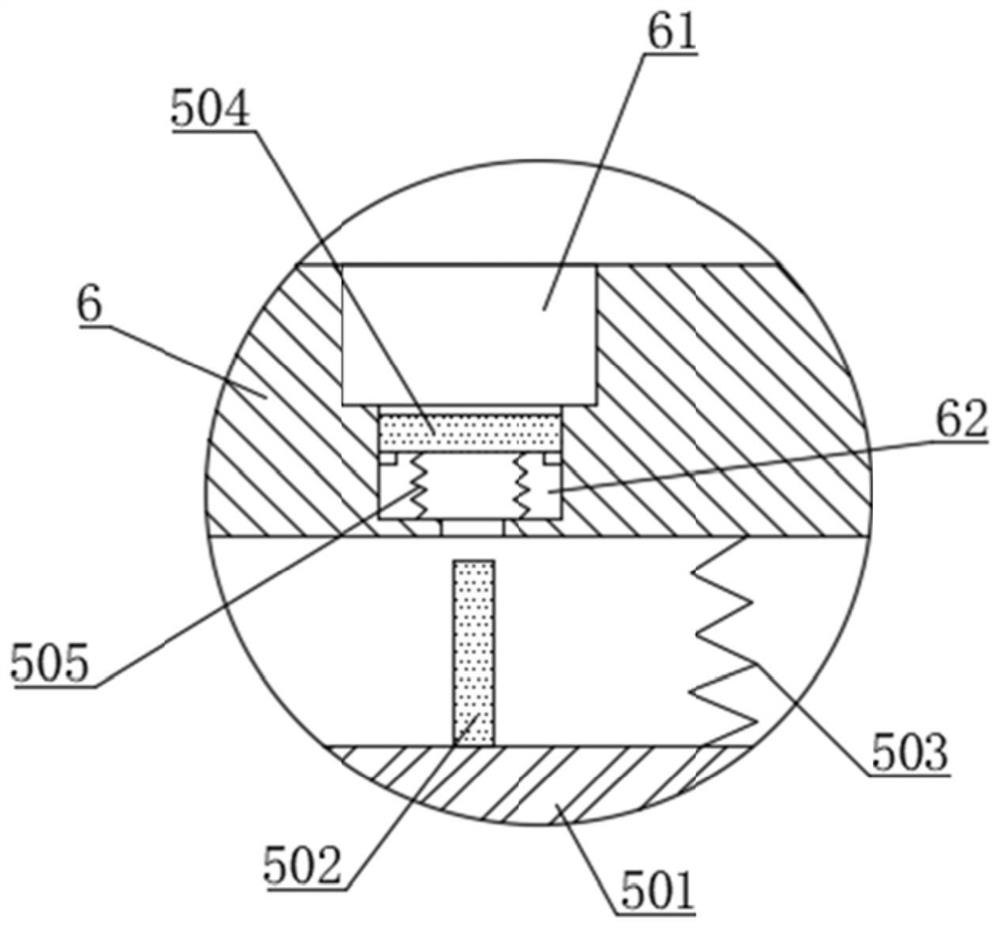

[0061] like figure 1 and Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a synchronous jacking assembly 5 is provided below the processing plate 6, and the synchronous jacking assembly 5 includes a top plate 501 and a pressure block 504, and the pressure groove 61 There is a storage tank 62 below, and the pressure bearing block 504 is arranged in the storage tank 62. The upper end surface of the pressure bearing block 504 is flush with the lower surface of the pressure tank 61, and the aperture of the storage tank 62 is smaller than the aperture of the pressure tank 61. To limit the pressure block 504, and the second return spring 505 connected to the pressure block 504 is installed in the storage groove 62, the top plate 501 is horizontally arranged below the processing plate 6, and the top of the top plate 501 is installed with a pressure post 502, and the number of pressing columns 502 is multiple groups and correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com