Electrostatic spray booth with purification function

An electrostatic spraying and electrostatic spraying technology, applied in the field of paint spraying room, can solve the problems of low capture rate, limited capture capacity, small surface area of water curtain, etc., and achieve the effect of increasing specific surface area and improving capture capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

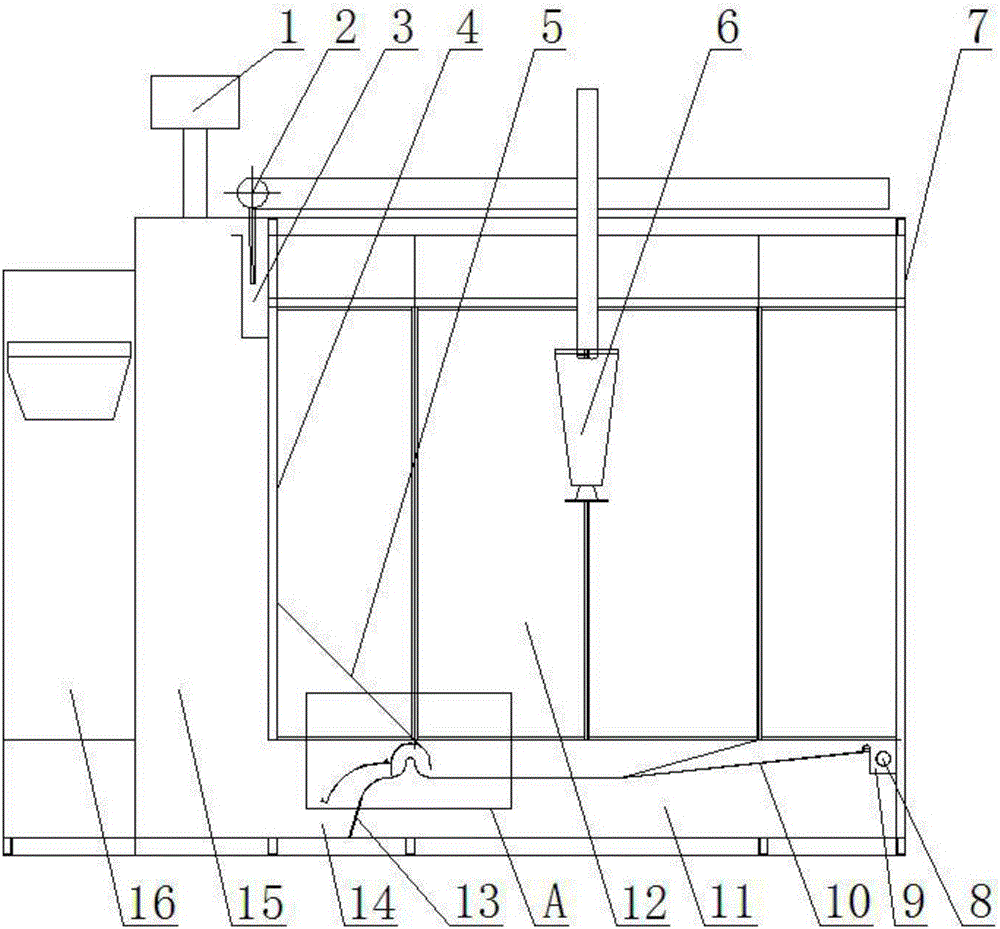

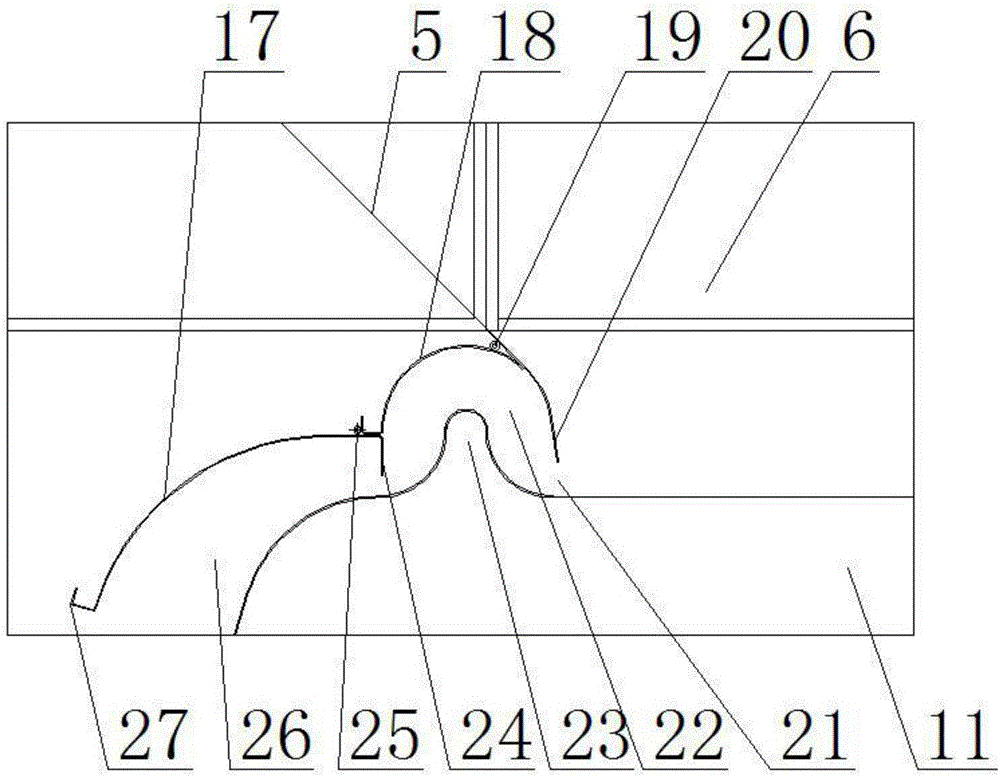

[0033] An electrostatic spray booth with purification function, including an electrostatic spray booth 7, in which an electrostatic spray nozzle 6 is installed, and a main water curtain board 4 and a side water curtain board 12 are arranged on the inner wall of the electrostatic spray booth. The back of the main water curtain board is connected to a steam-water separation chamber 15, and an induced draft fan 1 is installed above the steam-water separation chamber. The steam-water separation chamber is connected to a slag removal chamber 16 through a pipe. The lower part of the main water curtain board is set as an inclined flushing plate 5, and an electrostatic spray booth The dual atomized paint mist capturing structure connected by the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com