Device for pressure-dependent opening of a suction intake

A suction part and pressure technology, which is applied to the power plant, the arrangement combined with the fuel supply of the internal combustion engine, and packaging, can solve the problems of unfavorable sealing of the check valve and loss of effective vacuum degree, and achieve small pressure loss and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

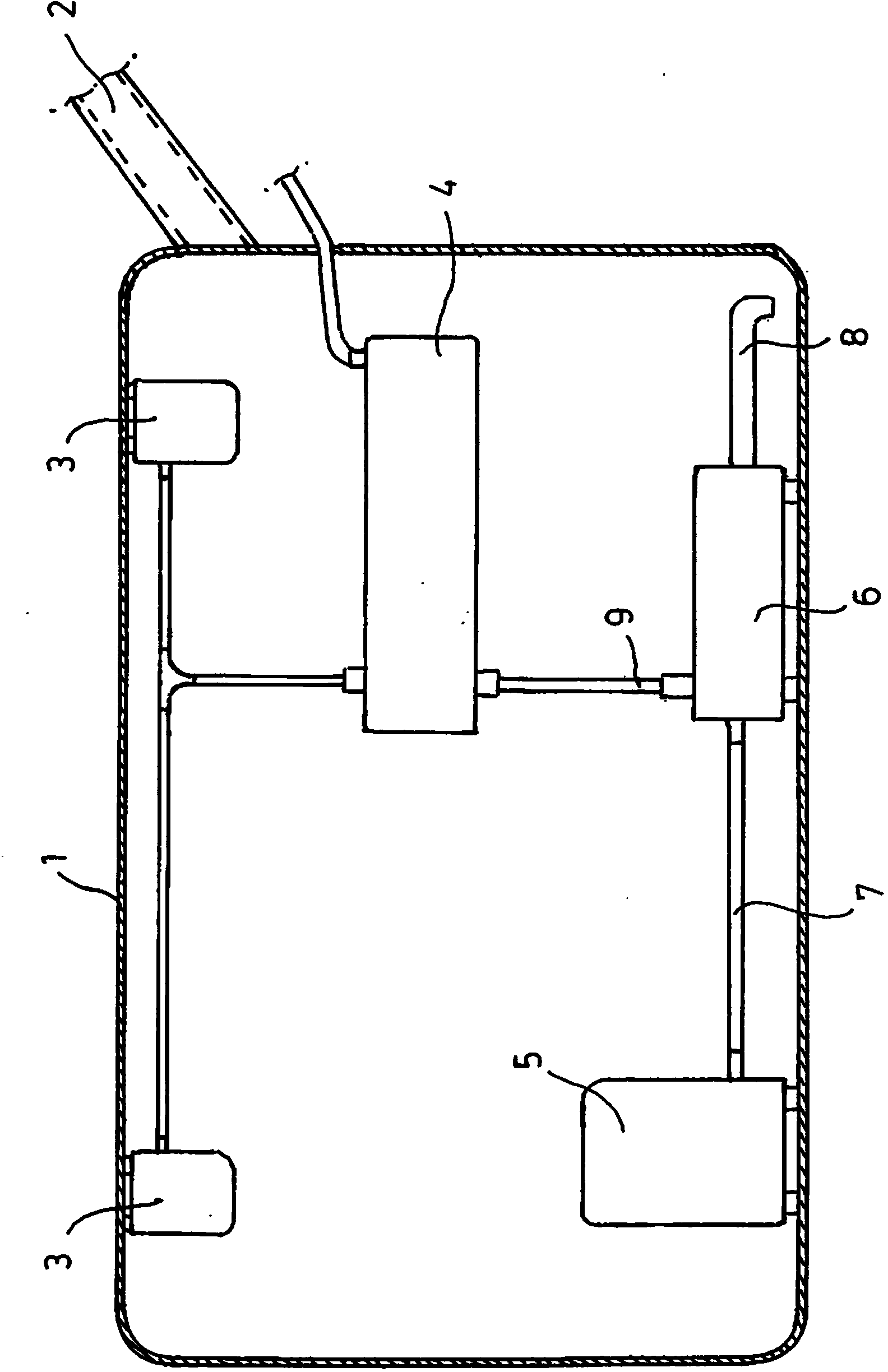

[0024] figure 1 A section of a fuel tank 1 is shown schematically, which has a cavity for receiving fuel. The fuel tank 1 includes a nozzle 2 for filling the fuel tank 1 with fuel.

[0025] The drain valve 3 is used to regulate the pressure in the fuel tank 1 , and the drain valve is arranged on the upper end of the fuel tank 1 , which is the installation position of the drain valve 3 .

[0026] The bubble extraction container 4 is used to separate fuel from fuel vapor, and the bubble extraction container is usually communicated with the surrounding environment through an activated carbon filter. Fuel accumulated in the air bubble extraction container 4 is efficiently extracted, for example, by means of a suction jet pump 11 . However, it must be ensured that no fuel enters the bubble extraction container 4 from the fuel tank 1 when the suction jet pump 11 is switched off.

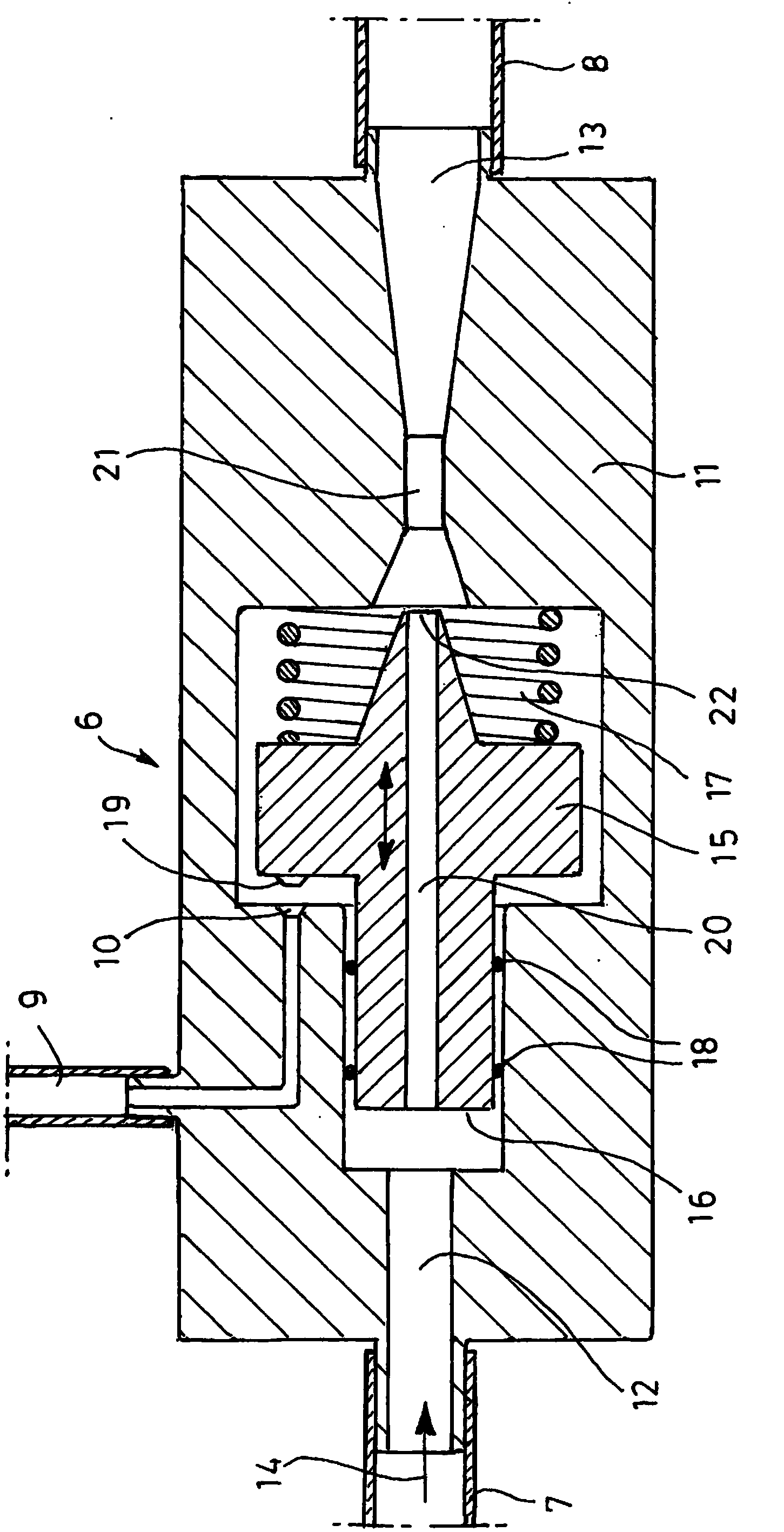

[0027] Therefore, according to the invention, the means 6 for opening the suction portion 10 as a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com