Large-sized workpiece electrostatic spraying booth

A technology of electrostatic spraying and large-scale workpieces, which is applied in the direction of liquid spraying equipment, coatings, and spray booths. High washing efficiency, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

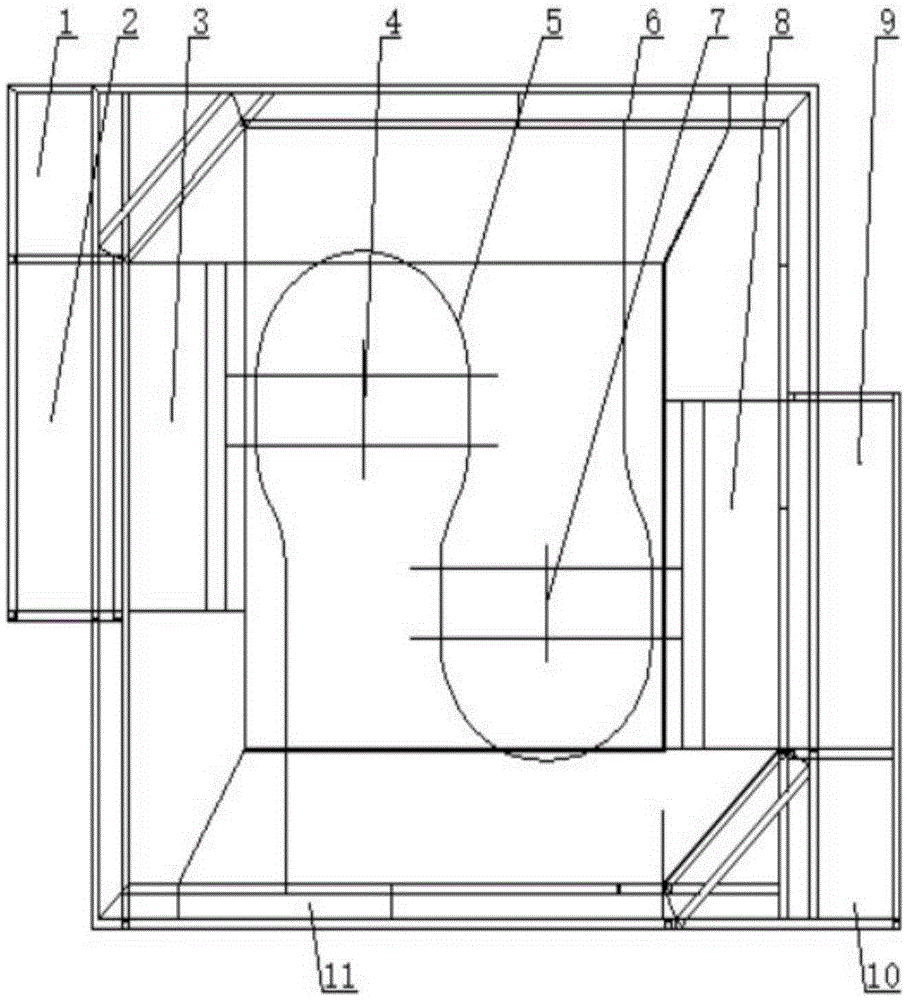

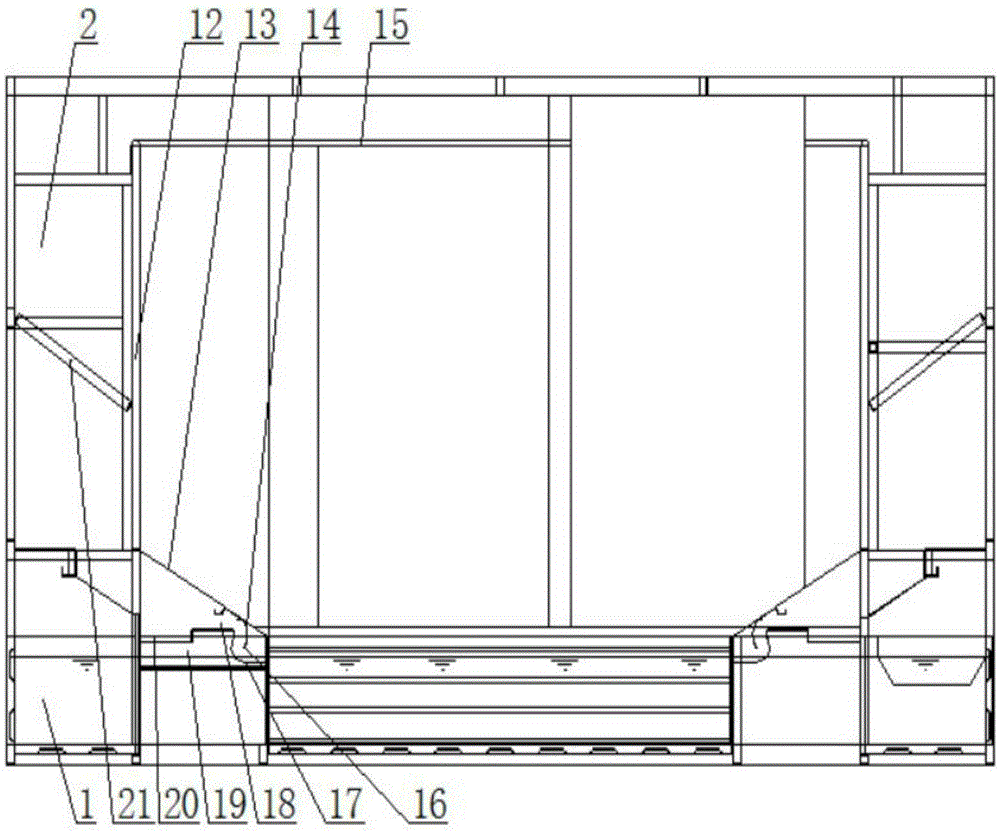

[0021] An electrostatic spraying room for large workpieces comprises a spraying room, water curtains 12 are installed on the four walls of the spraying room, and overflow tanks 15 are arranged on the top of the water curtains. It sets the first electrostatic nozzle 7 and the second electrostatic nozzle 4 in the spraying room, and the first electrostatic nozzle and the second electrostatic nozzle are arranged alternately, wherein the workpiece inlet 6 is set on the inner wall of the spraying room corresponding to the first electrostatic nozzle, and the second electrostatic nozzle The workpiece outlet 11 is set on the inner wall of the corresponding spraying room on the other side, so that the slideway 5 rotates once along the workpiece inlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com