Swash plate compressor with rotary valve

A rotary valve and swash plate technology, applied in liquid variable capacity machinery, mechanical equipment, engine components, etc., can solve the problems of poor durability of the drive shaft, inability to inhale refrigerant, etc., and achieve the effect of improving volumetric efficiency and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

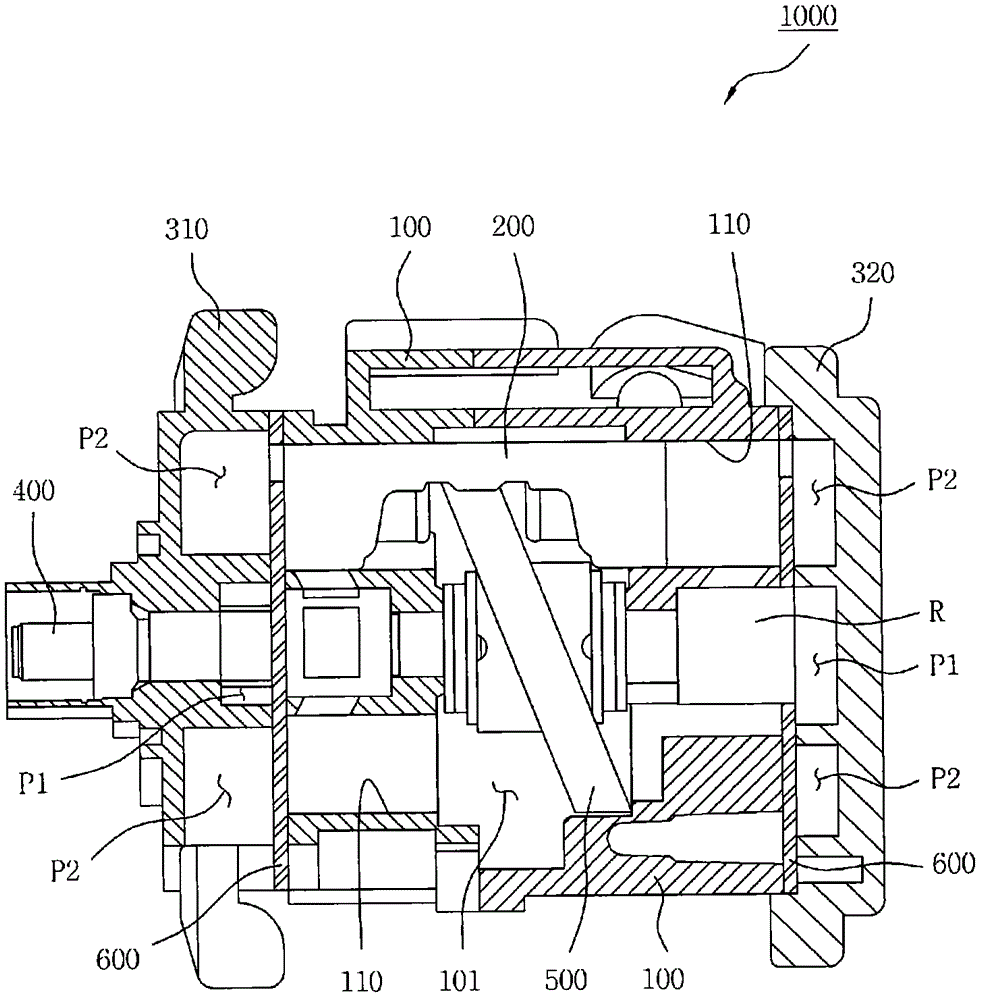

[0048] Such as Figure 3 to Figure 7 As shown in , the swash plate compressor 1000 according to the present invention includes: a cylinder block 100, which has a plurality of cylinder bores 110; a plurality of pistons 200, which are reciprocally accommodated in the cylinder bores 110 of the cylinder block 100; A front housing 310 and a rear housing 320, which are hermetically connected to the front and rear sides of the cylinder block 100, respectively; a drive shaft 400, which is installed to be rotatable relative to the front housing 310 and the cylinder block 100; installed to move in conjunction with the drive shaft 400 and the piston 200; a pair of valve discs 600 interposed between the cylinder block 100 and the front casing 310 and the rear casing 320, respectively.

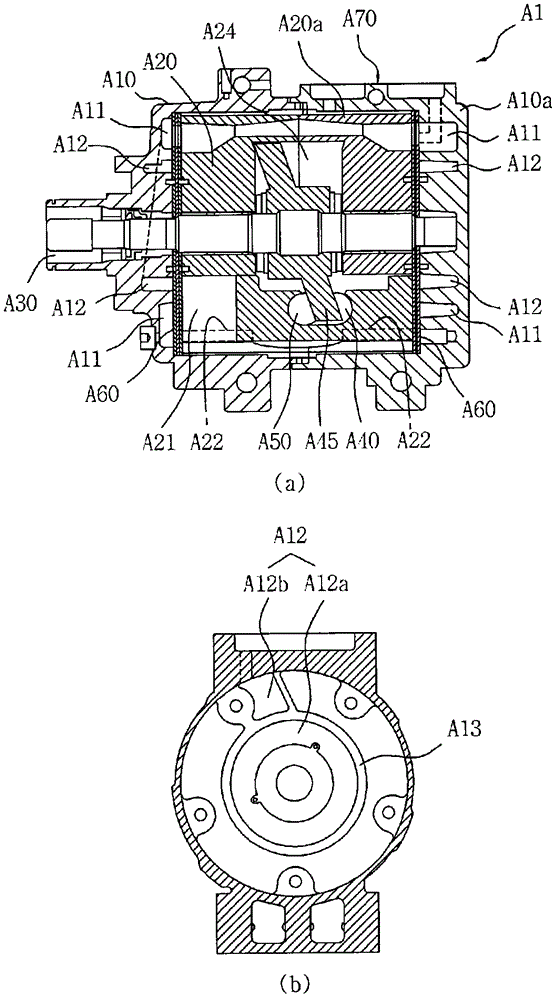

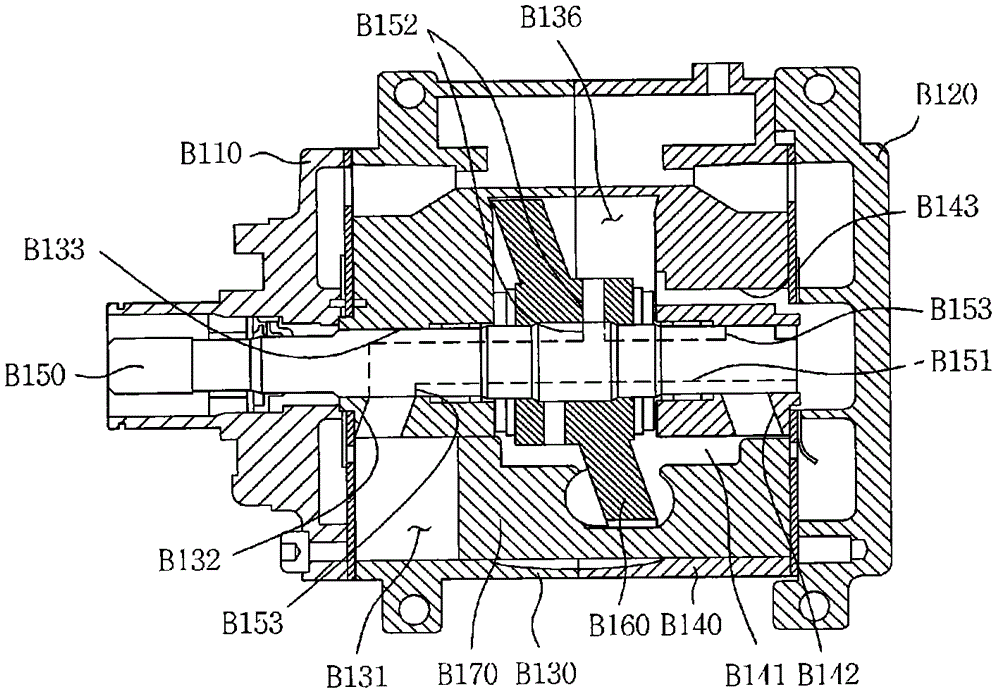

[0049] The above setting of the swash plate compressor and figure 1 and figure 2 The settings of the conventional technology are the same, therefore, the same settings will not be repeated but only diff...

Embodiment 2

[0077] In the following, reference will be made to Figure 8 to Figure 11 A second embodiment of the present invention is described in detail.

[0078] The swash plate type compressor 1000 according to the present invention includes: a cylinder block 100 having a plurality of cylinder bores 110; a plurality of pistons 200 reciprocally housed in the cylinder bores 110 of the cylinder block 100; a front housing 310 and rear housing 320, which is hermetically connected to the front and rear sides of the cylinder block 100, respectively; the drive shaft 400, which is installed to be rotatable relative to the front housing 310 and the cylinder block 100; the swash plate 500, which is installed to combine the drive The shaft 400 and the piston 200 are moved; a pair of valve discs 600 are respectively interposed between the cylinder block 100 and the front housing 310 and the rear housing 320 .

[0079] Likewise, since the above setup of the swash plate compressor is the same as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com