Double atomized paint mist capture structure

A paint mist and dual technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc., can solve the problems of limited capture capacity, low capture rate, low capture rate of water curtain plate, etc., to improve the capture capacity , the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

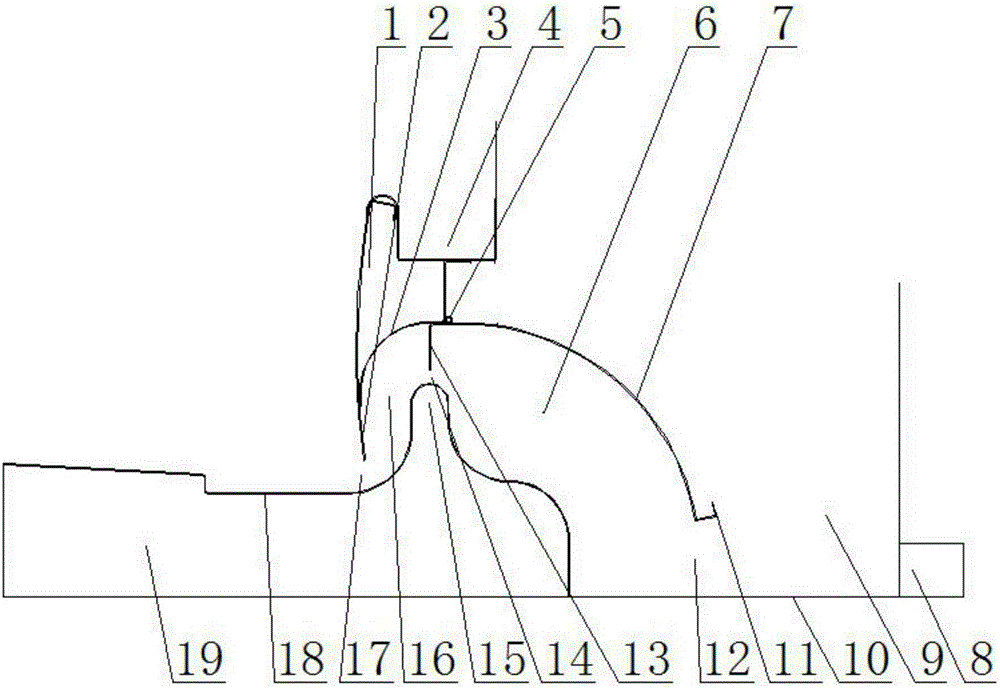

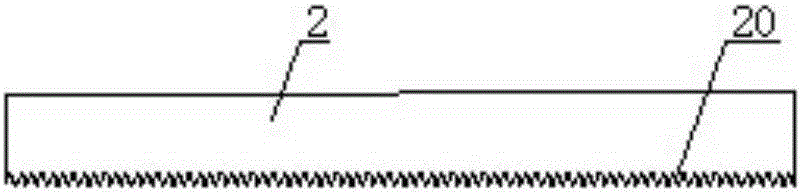

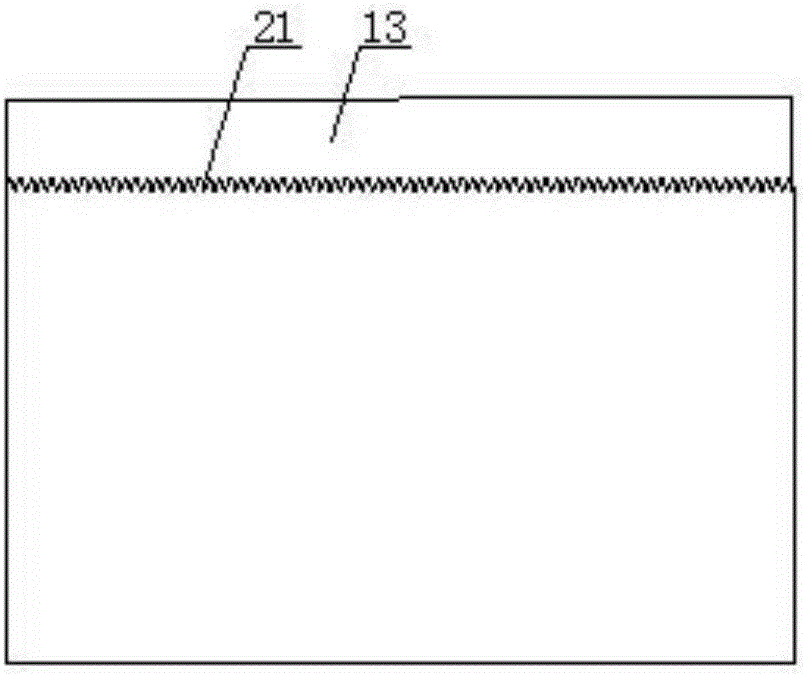

[0025] A double-atomized paint mist capture structure, including a water curtain plate 1, which also includes a bottom plate flow guide structure 19, and a main sawtooth plate 2. The sawtooth 20 on the main sawtooth plate is arranged at the lower end and is arranged along the entire length. The water curtain plate is set Above the flow diversion structure of the bottom plate, the main sawtooth plate is fixedly installed at the bottom of the water curtain plate, and the side of the water curtain plate above the main sawtooth plate is connected to the overflow tank 4 . The bottom end of the water curtain plate is shaped on an arc-shaped lifting section 3, and a flow-guiding sawtooth plate 13 is installed on the side wall of the water-curtain pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com