On-line petroleum product-caused copper sheet corrosion detection instrument and using method thereof

A technology for corrosion detection and petroleum products, which is applied in the field of on-line corrosion detection instruments for copper sheets of petroleum products, and can solve problems such as residue, adhesion, and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

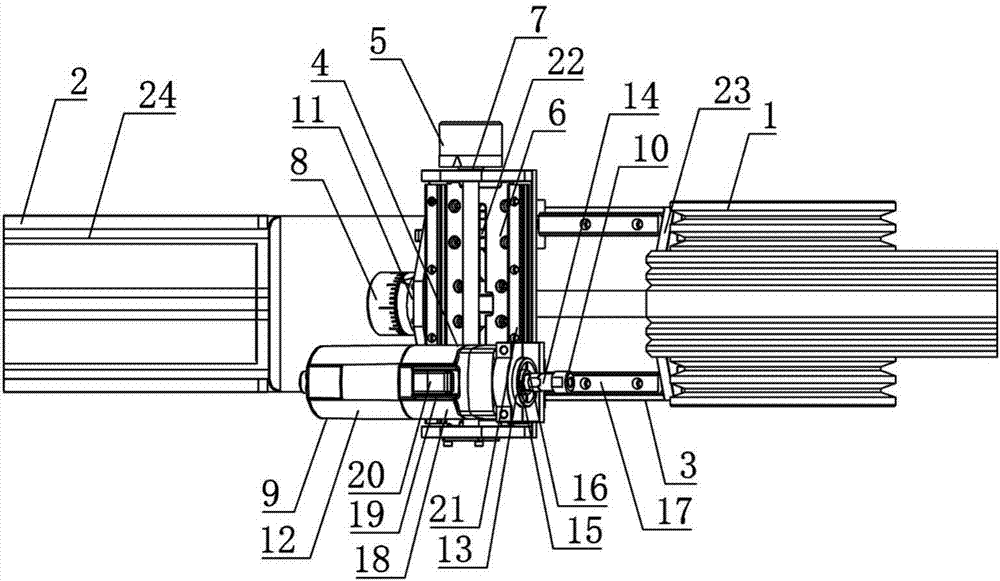

[0029] Such as figure 1 As shown, the on-line corrosion detection instrument for copper sheets of petroleum products includes a conveyor belt 1, a grinding structure and a turnover table 2, the grinding structure includes a grinding chute 3, a clamping fixture 4 that slides up and down along the grinding chute 3, and a clamping fixture 4 Including a first motor 5, a clamping carriage 6, a first rotating shaft 7 for controlling the action of the clamping carriage 6, a second motor 8, a clamping head 9, a rotating block 10 positioned at the end of the clamping head 9, and On the second rotating shaft 11 that controls the movement of the rotating block 10, the first motor 5 controls the clamping carriage 6 to move up and down through the first rotating shaft 7; the second motor 8 controls the rotating motion of the rotating block 10 through the second rotating shaft 11; the clamping head 9 Including an outer sleeve 12, an inner sleeve 13, a telescopic shaft 14, a push shaft 15, a...

Embodiment 2

[0035] Such as figure 1As shown, the on-line corrosion detection instrument for copper sheets of petroleum products includes a conveyor belt 1, a grinding structure and a turnover table 2, the grinding structure includes a grinding chute 3, a clamping fixture 4 that slides up and down along the grinding chute 3, and a clamping fixture 4 Including a first motor 5, a clamping carriage 6, a first rotating shaft 7 for controlling the action of the clamping carriage 6, a second motor 8, a clamping head 9, a rotating block 10 positioned at the end of the clamping head 9, and On the second rotating shaft 11 that controls the movement of the rotating block 10, the first motor 5 controls the clamping carriage 6 to move up and down through the first rotating shaft 7; the second motor 8 controls the rotating motion of the rotating block 10 through the second rotating shaft 11; the clamping head 9 Including an outer sleeve 12, an inner sleeve 13, a telescopic shaft 14, a push shaft 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com