Plane grinding block tool

A sponge and grinding block technology, applied in the field of grinding tools, can solve problems affecting construction progress and construction quality, hand discomfort, single shape and structure, etc., and achieve the effect of repeated utilization, convenient and comfortable use, and convenient processing and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

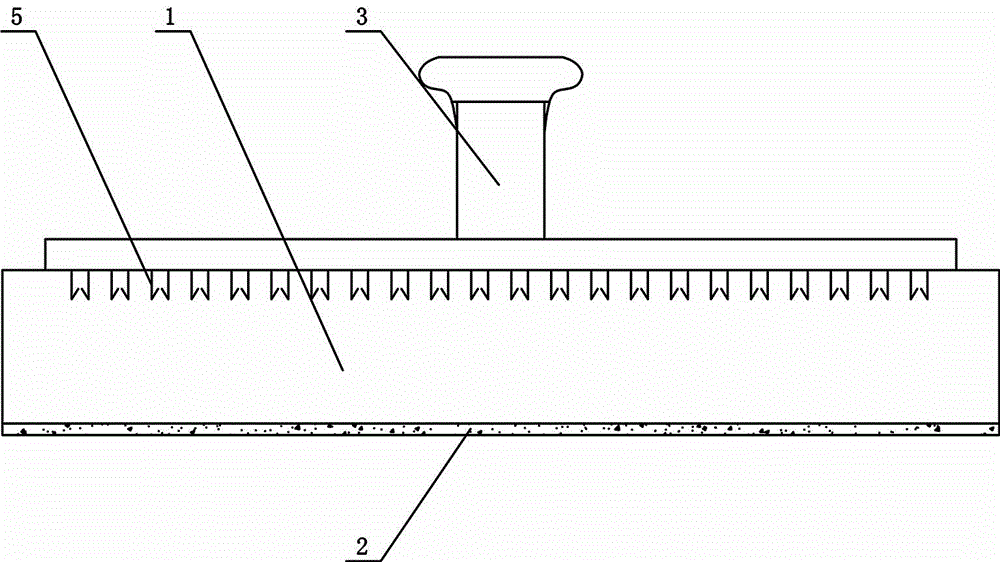

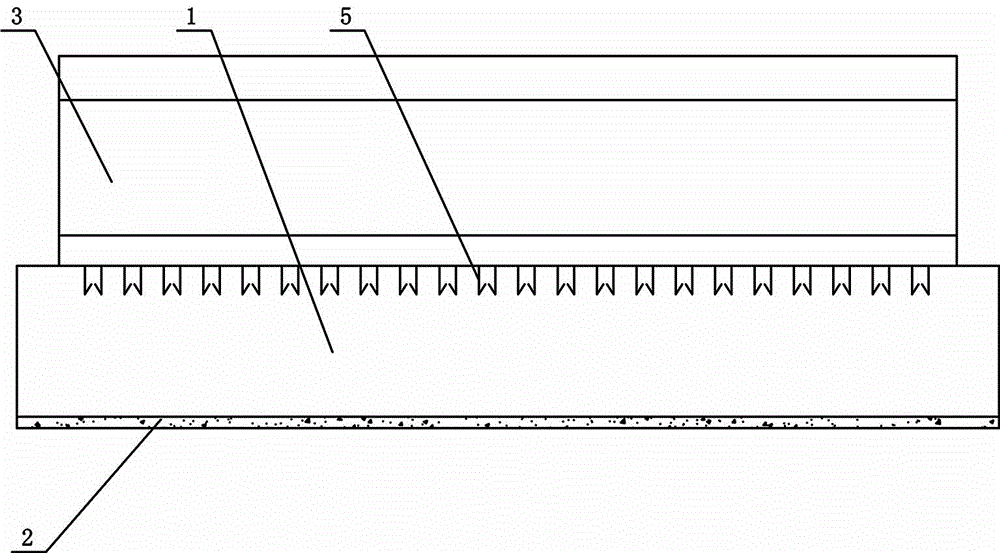

[0018] Such as figure 1 Among them, a flat sponge grinding block tool, the lower end surface of the sponge inner core 1 is covered with a layer of frosted layer 2; the upper end surface of the sponge inner core 1 is provided with a hand plate 3.

[0019] With this structure, a hand plate is added to the upper end of the sponge grinding block. The user controls the sponge grinding block by holding the hand plate during use, and does not need to touch the frosting layer with hands, avoiding a long time between the grinding layer and the grinding layer. Hand discomfort due to contact friction.

[0020] In a preferred solution, the said hand plate 3 is an "I" shaped hand plate or a "T" shaped hand plate.

[0021] In a preferred solution, barbs 5 are provided on the end surface of the hand plate 3 in contact with the sponge inner core 1 . The set barb 5 is used to better fix the sponge grinding block and the hand plate.

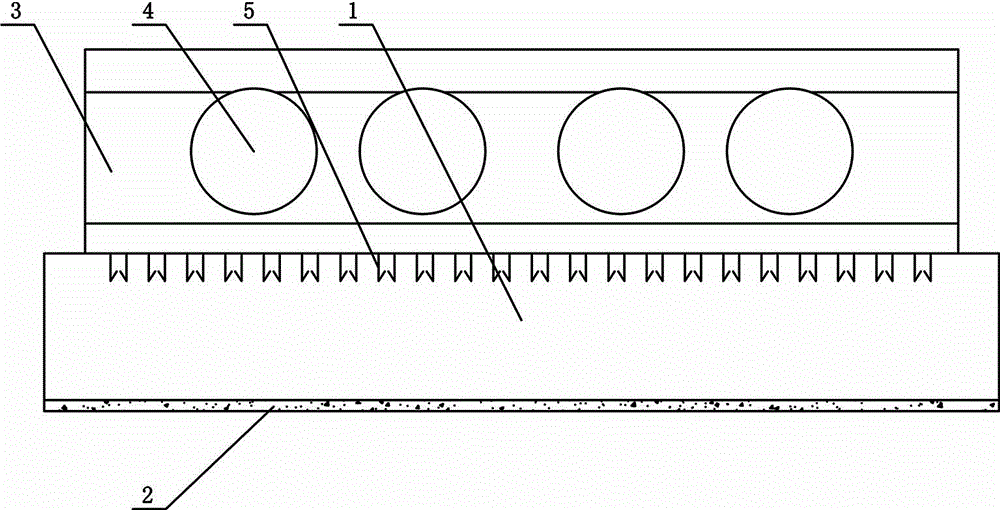

[0022] The preferred solution is as image 3 Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com