Environment-friendly light-curing electrostatic spraying primer

An electrostatic spraying, light curing technology, applied in epoxy resin coatings, coatings, polyester coatings, etc., can solve the problems of high surface tension, poor electrostatic coating effect, poor sandability, etc. Good performance, good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

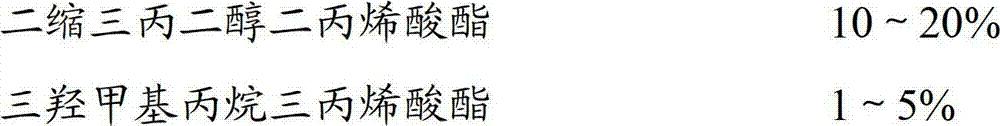

[0022] An environmentally friendly light-curing electrostatic spraying primer, which contains components and the mass percentages of each component are as follows:

[0023]

[0024]

[0025] The epoxy resin is a modified epoxy acrylic resin, which is 3819 from Junli Company.

[0026] Described polyester resin is polyester acrylic resin, selects 6316 of ETERNAL company for use.

[0027] The polyurethane resin is an aliphatic modified polyurethane acrylic resin, which is 4204E from Chiba Company.

[0028] The leveling agent is an oil-based leveling agent, and BYK's polyacrylate solution is selected.

[0029] Described powder quality is the talcum powder of 99%.

[0030] The defoamer is an oily defoamer, and the non-silicon defoamer of TEGO is selected for use.

[0031] The preparation method of described environment-friendly photocuring electrostatic spraying primer comprises the following specific steps:

[0032] Step A, weighing tripropylene glycol diacrylate, trimet...

Embodiment 2

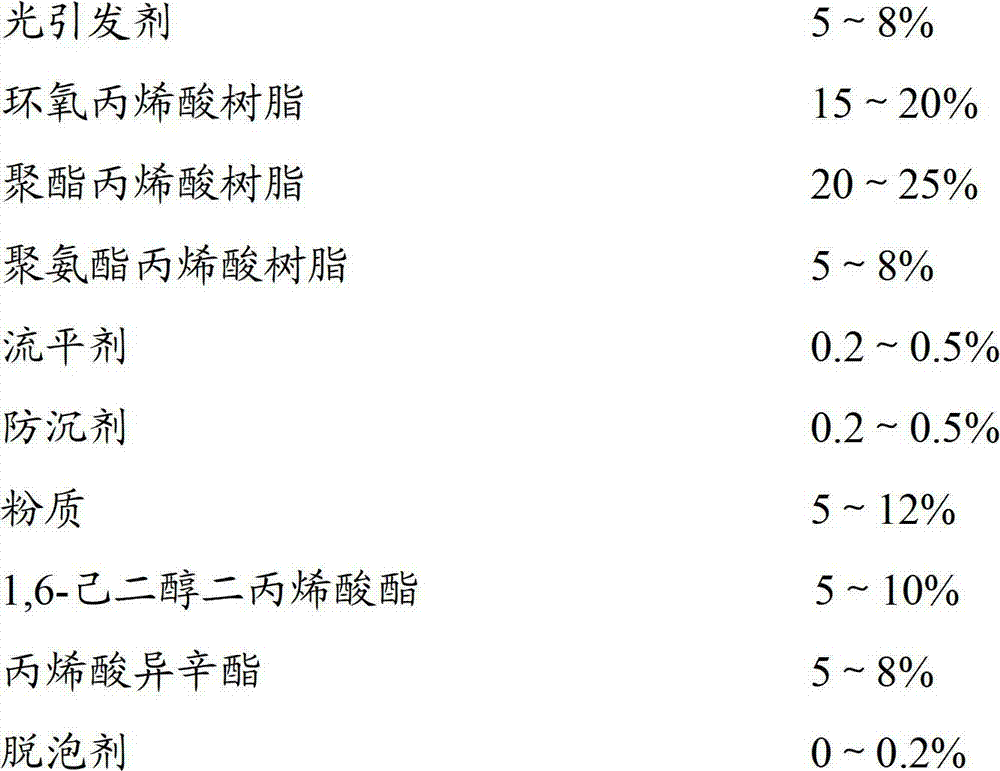

[0037] An environmentally friendly light-curing electrostatic spraying primer, which contains components and the mass percentages of each component are as follows:

[0038]

[0039] The epoxy resin is a modified epoxy acrylic resin, which is 3819 from Junli Company.

[0040] Described polyester resin is polyester acrylic resin, selects 6316 of ETERNAL company for use.

[0041] The polyurethane resin is an aliphatic modified polyurethane acrylic resin, which is 4204E from Chiba Company.

[0042] The leveling agent is an oil-based leveling agent, and BYK's polyacrylate solution is selected.

[0043] Described powder quality is the talcum powder of 99%.

[0044] The defoamer is an oily defoamer, and the non-silicon defoamer of TEGO is selected for use.

[0045] The preparation method of described environment-friendly photocuring electrostatic spraying primer comprises the following specific steps:

[0046] Step A, weighing tripropylene glycol diacrylate, trimethylolpropane...

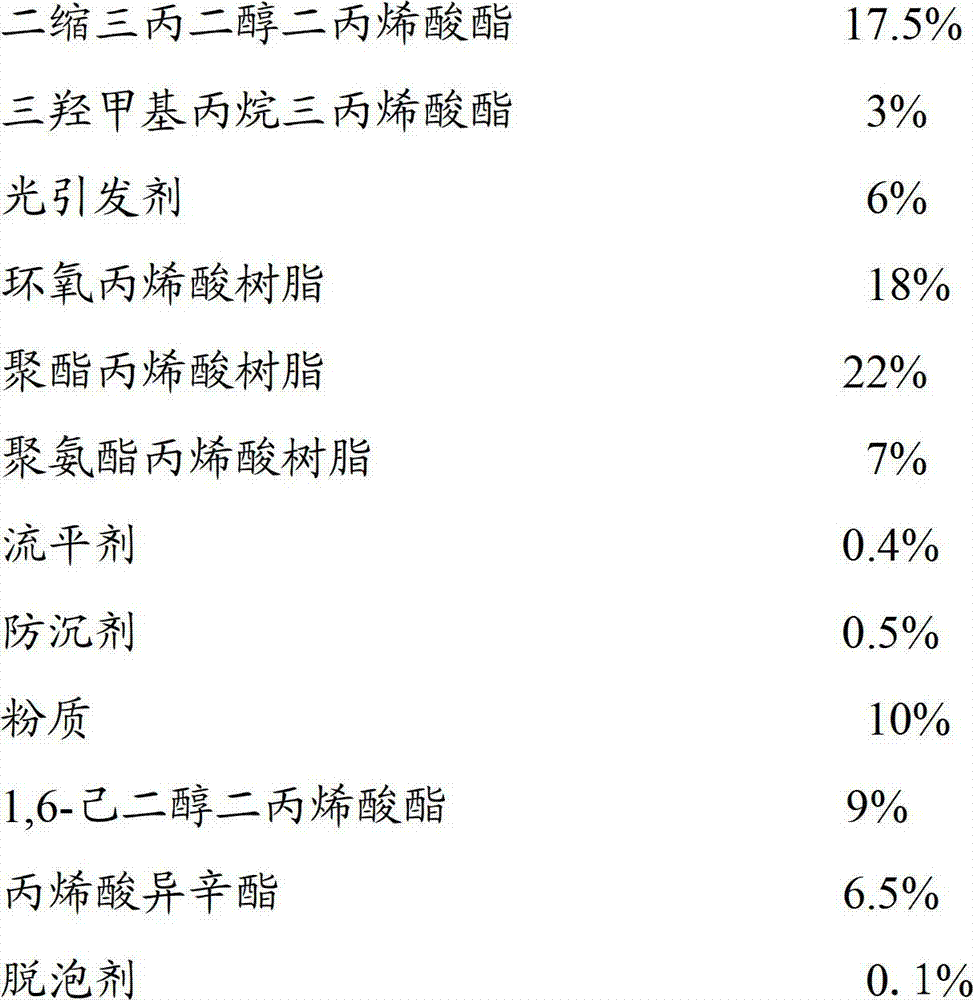

Embodiment 3

[0051]

[0052] The epoxy resin is a modified epoxy acrylic resin, which is 3819 from Junli Company.

[0053] Described polyester resin is polyester acrylic resin, selects 6316 of ETERNAL company for use.

[0054] The polyurethane resin is an aliphatic modified polyurethane acrylic resin, which is 4204E from Chiba Company.

[0055] The leveling agent is an oil-based leveling agent, and BYK's polyacrylate solution is selected.

[0056] Described powder quality is the talcum powder of 99%.

[0057] The defoamer is an oily defoamer, and the non-silicon defoamer of TEGO is selected for use.

[0058] The preparation method of described environment-friendly photocuring electrostatic spraying primer comprises the following specific steps:

[0059] Step A, weighing tripropylene glycol diacrylate, trimethylolpropane triacrylate, photoinitiator, epoxy acrylic resin, polyester acrylic resin, polyurethane acrylic resin, leveling agent, anti-settling agent, Powder, 1,6-hexanediol di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com