Nitrocellulose transparent primer and application thereof

A transparent primer and nitro technology, applied in coatings, polyester coatings, natural resin coatings, etc., can solve the problems of waste of resources, pollution of the environment, time-consuming and other problems, to reduce environmental pollution, and to achieve good film filling. , the effect of reducing the number of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

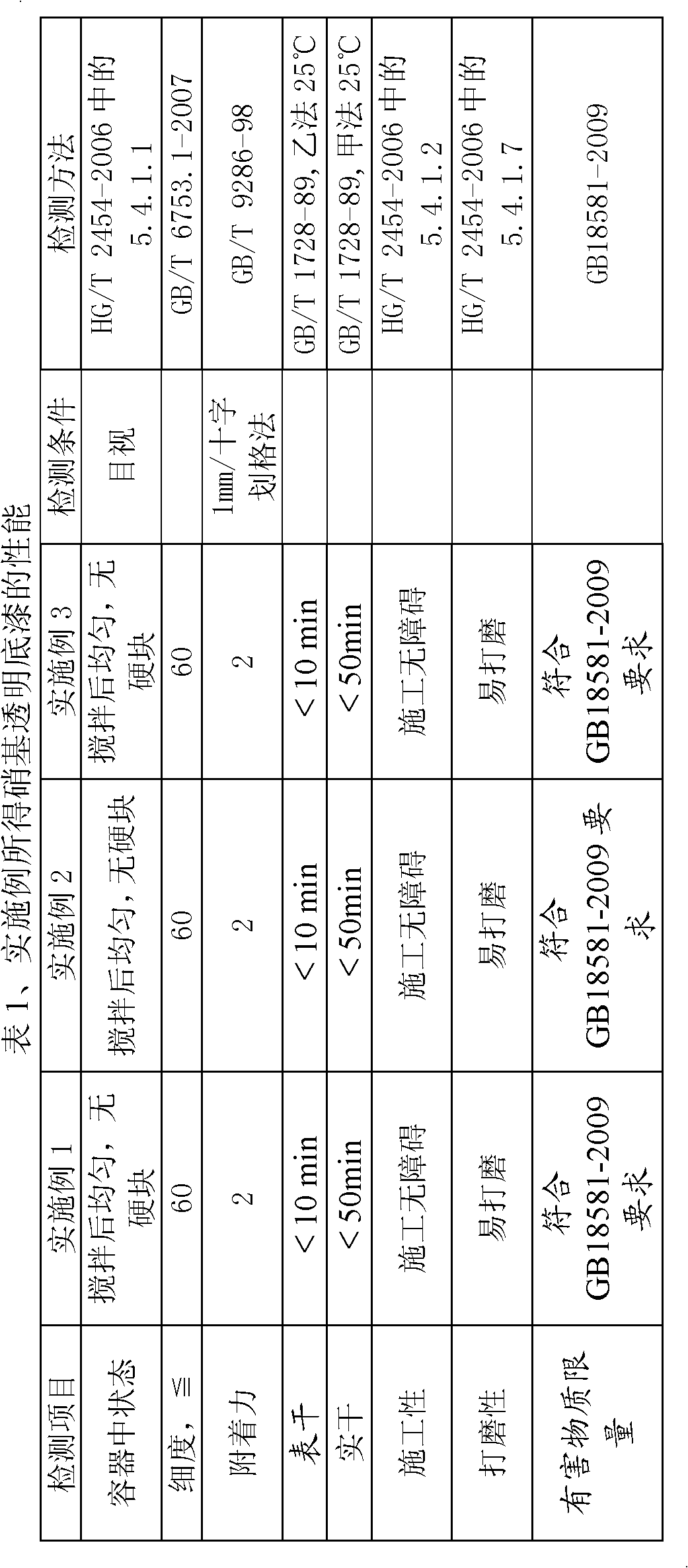

Examples

Embodiment 1

[0036] A kind of nitro transparent primer, is prepared by following method:

[0037] (1) Preparation of main paint: Weigh 210g of soybean oil short oil alkyd (Changxing Chemical) and put it into the dispersion tank, stir; weigh 2g of wetting and dispersing agent (EFKA), 30g of main paint solvent and slowly add to the mixture containing soybean oil short oil In the oil alkyd dispersion tank, stir evenly at a speed of 600-800r / min; weigh 500g of nitrocellulose solution (Dekang), 50g of epoxy soybean oil, and 60g of maleic acid modified rosin resin and add them to the dispersion tank. Stir evenly at a stirring speed of 800-1000r / min, then slowly add 5g of anti-sedimentation agent organic bentonite, 40g of grinding aid zinc stearate, 80g of talc powder, and 20g of microsilica powder into the dispersion tank while stirring. Increase to 2000-2500r / min and disperse for 20-25min until the fineness is ≤60um. Finally, 2g of silicone defoamer (purchased from BASF, Germany), 1g of anti-ye...

Embodiment 2

[0042] A kind of nitro transparent primer, is prepared by following method:

[0043] (1) Preparation of main paint: Weigh 230g of soybean oil short oil alkyd (Jiangmen paint) and put it into the dispersion tank, stir; weigh 2g of wetting and dispersing agent (EFKA), 30g of main paint solvent and slowly add to the mixture containing soybean oil In the short-oil alkyd dispersion tank, stir evenly at a speed of 600-800r / min; weigh 470g of nitrocellulose solution (Dekang), 40g of epoxy soybean oil, and 70g of maleic acid modified rosin resin and add them to the dispersion tank , stir evenly at a stirring speed of 800-1000r / min, then slowly add 5g of anti-sedimentation agent organic bentonite, 50g of grinding aid zinc stearate, 70g of talcum powder, and 20g of transparent powder into the dispersion tank while stirring, and put Increase the rotation speed to 2000-2500r / min and disperse for 20-25min until the fineness is ≤60um. Finally, add 2g of silicone defoamer (purchased from BAS...

Embodiment 3

[0048] A kind of nitro transparent primer, is prepared by following method:

[0049](1) Preparation of the main paint: Weigh 250g of soybean oil short oil alkyd (Changxing Chemical) and put it into the dispersion tank, stir; weigh 2g of wetting and dispersing agent (EFKA) and 30g of main paint solvent and slowly add it to the mixture containing soybean oil short oil In the oil alkyd dispersion tank, stir evenly at a speed of 600-800r / min; weigh 450g of nitrocellulose solution (Dekang), 30g of epoxy soybean oil, and 60g of maleic acid modified rosin resin and add them to the dispersion tank. Stir evenly at a stirring speed of 800-1000r / min, then slowly add 5g of anti-sedimentation agent organic bentonite, 60g of grinding aid zinc stearate, 60g of talc powder, and 20g of silicon micropowder into the dispersing tank while stirring. Increase to 2000-2500r / min and disperse for 20-25min until the fineness is ≤60um. Finally, 2g of silicone defoamer (purchased from BASF, Germany), 1g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com