Ultra-strong water-resistant mildew-resistant inorganic dry powder putty

A technology of inorganic dry powder and putty, applied in the direction of filling slurry, etc., can solve the problems of high density of putty, poor leveling effect, no elasticity, etc., and achieve the effect of good sandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

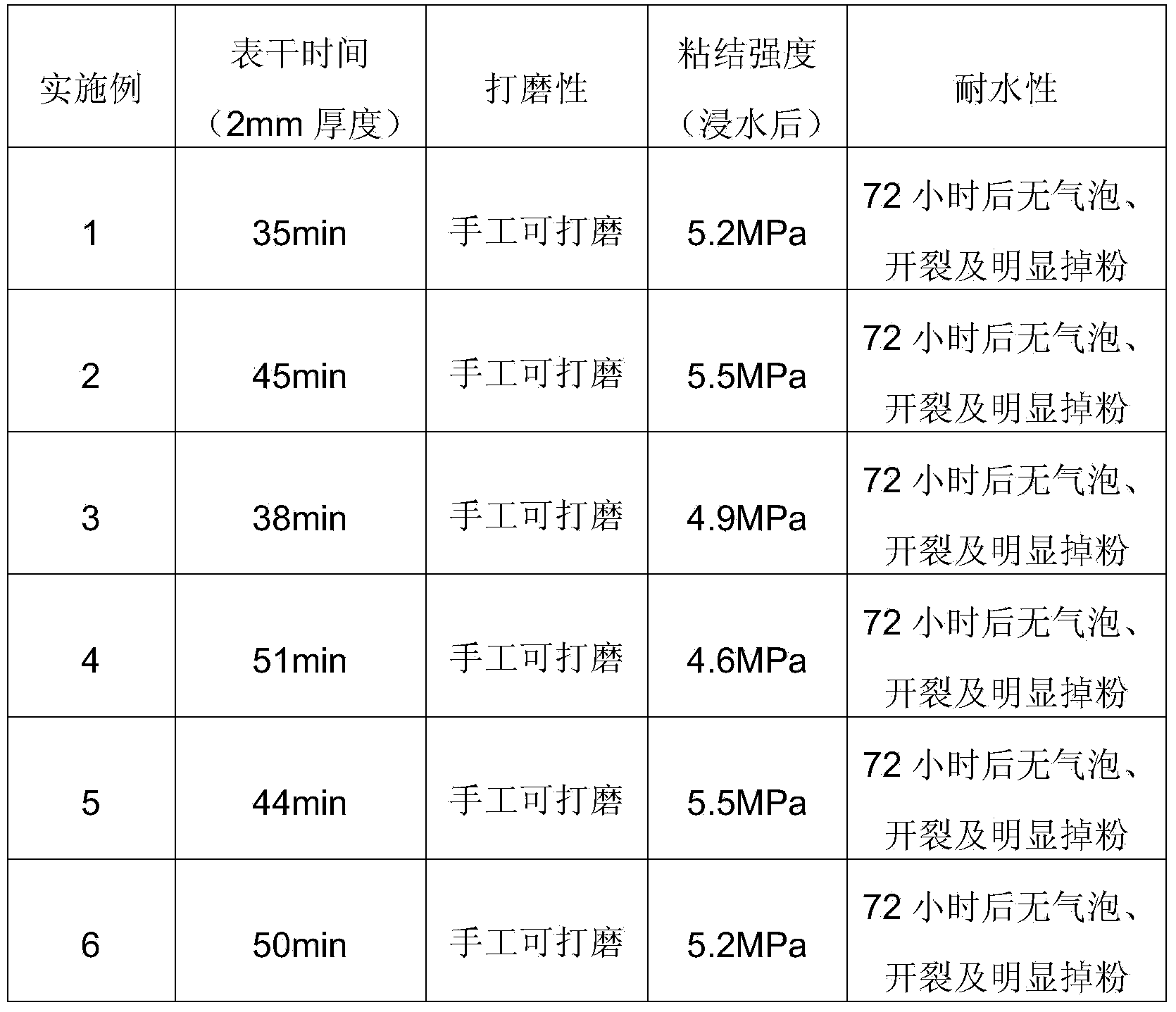

Embodiment 1

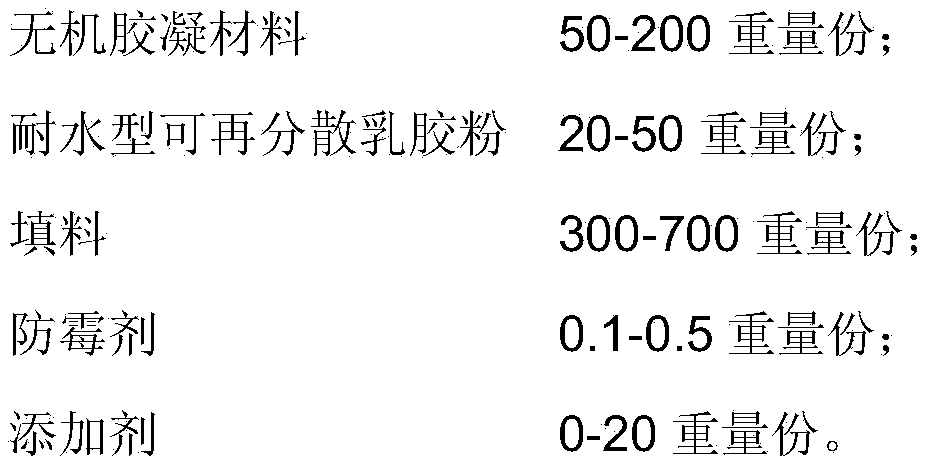

[0048] In the present embodiment, the water-resistant and mildew-proof putty components are:

[0049] Cement 100kg, lime 20kg, ethylene / propylene binary copolymer redispersible latex powder 20kg, silicon dioxide 50kg, barium carbonate 100kg, magnesium hydroxide 150kg, benzimidazole 0.2kg.

Embodiment 2

[0051] In the present embodiment, the water-resistant and mildew-proof putty components are:

[0052] Cement 80kg, lime 50kg, vinyl acetate / ethylene tertiary carbonate binary copolymer redispersible latex powder 35kg, aluminum silicate 100kg, barium carbonate 100kg, silicon oxide 100kg, benzimidazole 0.5kg.

Embodiment 3

[0054] In the present embodiment, the water-resistant and mildew-proof putty components are:

[0055] 60kg of cement, 25kg of lime, 50kg of gypsum, 50kg of ethylene / vinyl acetate binary copolymer redispersible latex powder, 200kg of barium sulfate, 100kg of kaolin, 150kg of silicon oxide, and 0.3kg of methylisothiazolinone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com