Two-component elastic anti-cracking waterproof putty for exterior walls

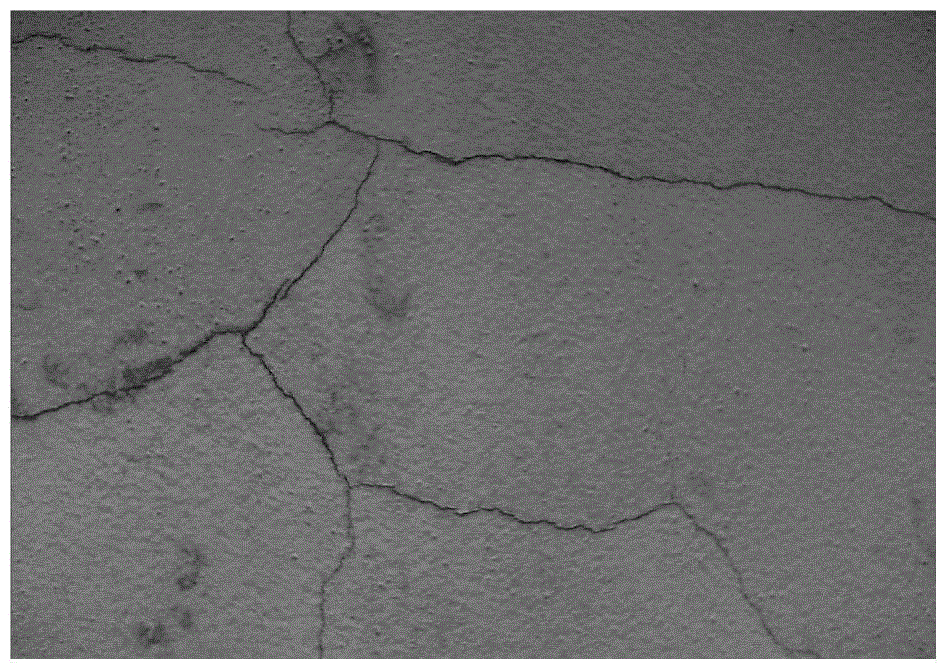

A two-component, anti-cracking technology, applied in the direction of filling slurry, etc., can solve the problems of low aging resistance, cracking, poor water resistance, etc., and achieve the effects of good sandability, high bonding strength and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

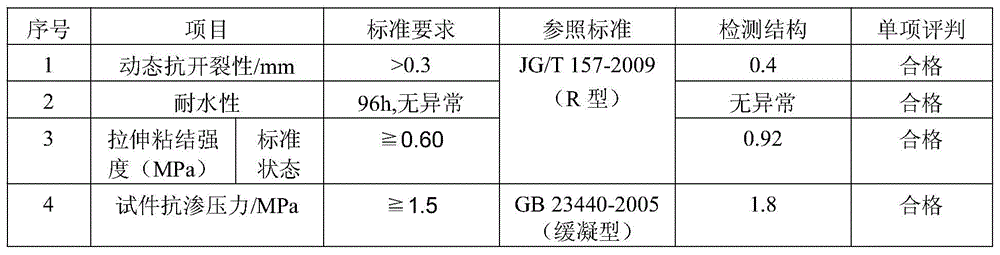

[0029] According to the content provided by the present invention, according to the conventional preparation method in the prior art, the inventor mixed the two-component external wall elastic anti-cracking waterproof putty with water to prepare two-component external wall putty 1, and the mass of the added water accounted for Wherein said two-component outer wall elastic anti-cracking waterproof putty is 20% of the mass, wherein the proportion of each component of said two-component outer wall elastic anti-cracking waterproof putty is as follows:

[0030] 10% cement, 40% fine quartz sand, 0.8% HPMC, 9.2% UEA expansion agent, 30% limestone powder, 5% dispersible latex powder, 5% elastic acrylic emulsion.

Embodiment 2

[0032] According to the content provided by the present invention, according to the conventional preparation method in the prior art, the inventor mixed the two-component external wall elastic anti-cracking waterproof putty with water to prepare two-component external wall putty 2, and the mass of the added water accounted for Wherein said two-component external wall elastic anti-cracking waterproof putty is 21% of the mass, wherein the proportion of each component of said two-component external wall elastic anti-cracking waterproof putty is as follows:

[0033] 50% cement, 10% fine quartz sand, 0.4% HPMC, 5% UEA expansion agent, 10% limestone powder, 4.6% dispersible latex powder, 15% elastic acrylic emulsion.

Embodiment 3

[0035] According to the content provided by the present invention, according to the conventional preparation method in the prior art, the inventor mixed the two-component external wall elastic anti-cracking waterproof putty with water to prepare two-component external wall putty 3, and the mass of the added water accounted for Wherein said two-component external wall elastic anti-cracking waterproof putty is 23% of the mass, wherein the proportion of each component of said two-component external wall elastic anti-cracking waterproof putty is as follows:

[0036] 30% cement, 30% fine quartz sand, 0.6% HPMC, 8% UEA expansion agent, 15% limestone powder, 3% dispersible latex powder, 13.4% elastic acrylic emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com