Arc-shaped part polishing equipment for construction machinery

A kind of construction machinery and arc-shaped technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding machines, etc., and can solve the problems of poor grinding effect, low grinding efficiency, uneven grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

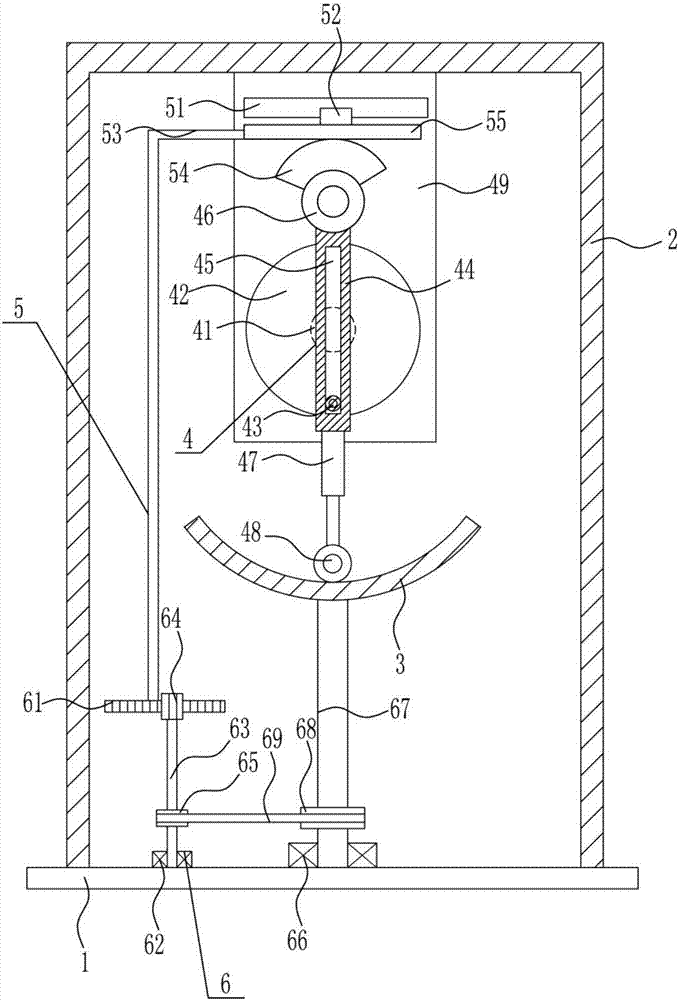

[0030] A kind of arc-shaped parts grinding equipment for construction machinery, such as Figure 1-3 As shown, it includes a bottom plate 1, an n-shaped frame 2, an arc-shaped placement plate 3, a grinding mechanism 4, a moving mechanism 5, and a rotating mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the top of the n-shaped frame 2 is provided with a grinding mechanism. Mechanism 4, a moving mechanism 5 is arranged above the polishing mechanism 4, a rotating mechanism 6 is arranged on the left side of the bottom plate 1 top, and an arc-shaped placement plate 3 is arranged on the top of the rotating mechanism 6.

Embodiment 2

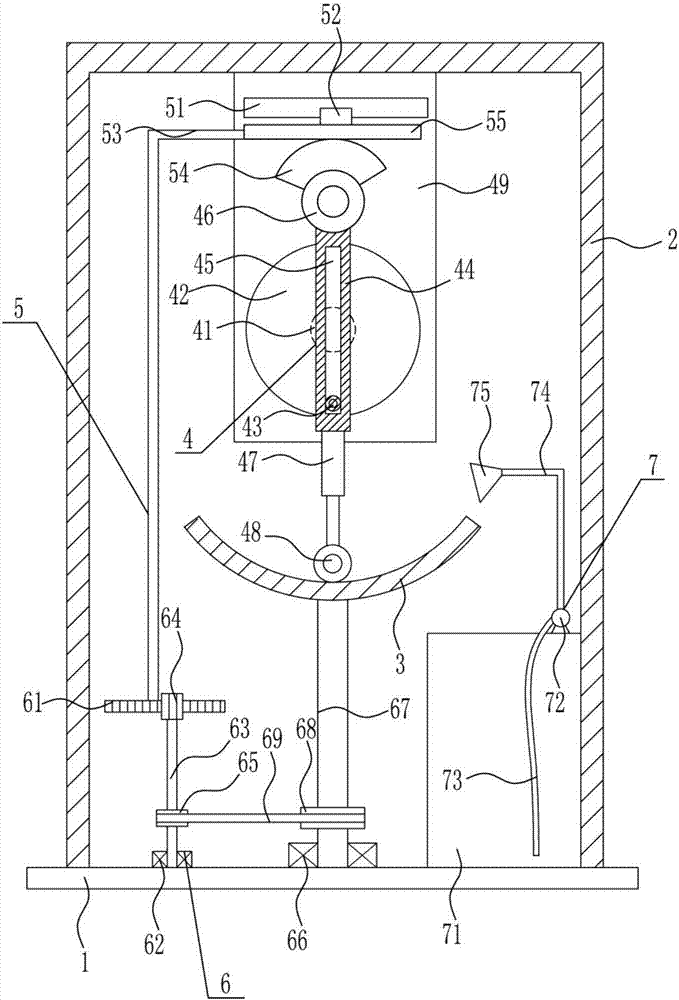

[0032] A kind of arc-shaped parts grinding equipment for construction machinery, such as Figure 1-3 As shown, it includes a bottom plate 1, an n-shaped frame 2, an arc-shaped placement plate 3, a grinding mechanism 4, a moving mechanism 5, and a rotating mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the top of the n-shaped frame 2 is provided with a grinding mechanism. Mechanism 4, a moving mechanism 5 is arranged above the polishing mechanism 4, a rotating mechanism 6 is arranged on the left side of the bottom plate 1 top, and an arc-shaped placement plate 3 is arranged on the top of the rotating mechanism 6.

[0033]Grinding mechanism 4 comprises motor 41, disc 42, roller 43, swing lever 44, first rotating shaft 46, electric push rod 47, grinding wheel 48 and fixed plate 49, and the inner top of n-shaped frame 2 is provided with fixed plate 49, The lower part of the front side of the fixed plate 49 is provided with a motor 41, the outp...

Embodiment 3

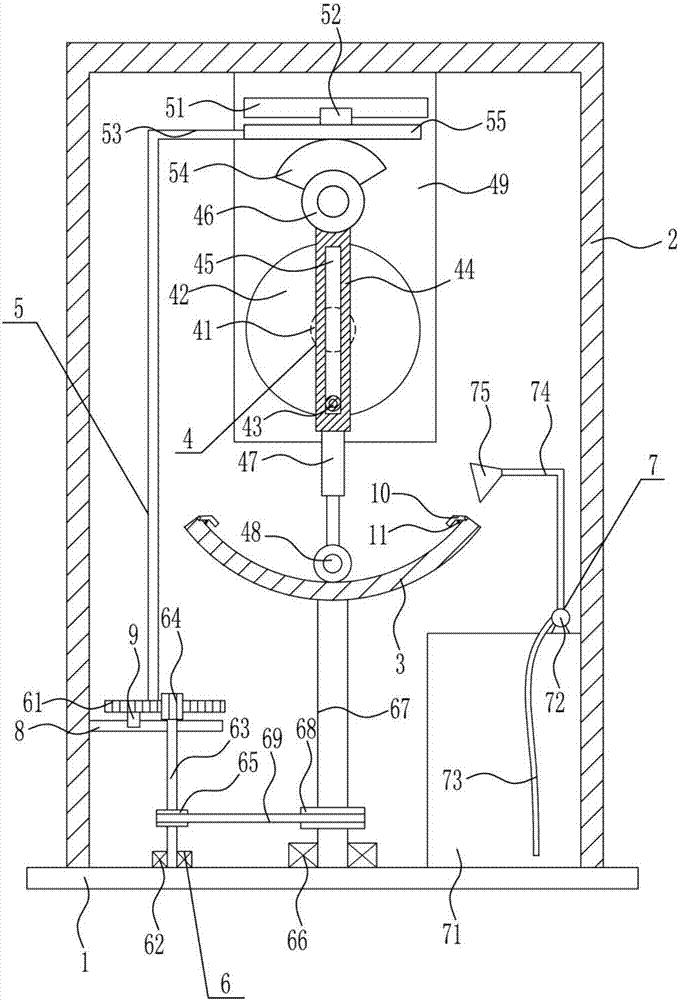

[0035] A kind of arc-shaped parts grinding equipment for construction machinery, such as Figure 1-3 As shown, it includes a bottom plate 1, an n-shaped frame 2, an arc-shaped placement plate 3, a grinding mechanism 4, a moving mechanism 5, and a rotating mechanism 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the top of the n-shaped frame 2 is provided with a grinding mechanism. Mechanism 4, a moving mechanism 5 is arranged above the polishing mechanism 4, a rotating mechanism 6 is arranged on the left side of the bottom plate 1 top, and an arc-shaped placement plate 3 is arranged on the top of the rotating mechanism 6.

[0036] Grinding mechanism 4 comprises motor 41, disc 42, roller 43, swing lever 44, first rotating shaft 46, electric push rod 47, grinding wheel 48 and fixed plate 49, and the inner top of n-shaped frame 2 is provided with fixed plate 49, The lower part of the front side of the fixed plate 49 is provided with a motor 41, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com