Special-shaped wooden strip sanding grinder

A sanding machine and wood line technology, which is used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of poor sanding quality, dead corners, low efficiency, etc., to reduce production costs and achieve a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

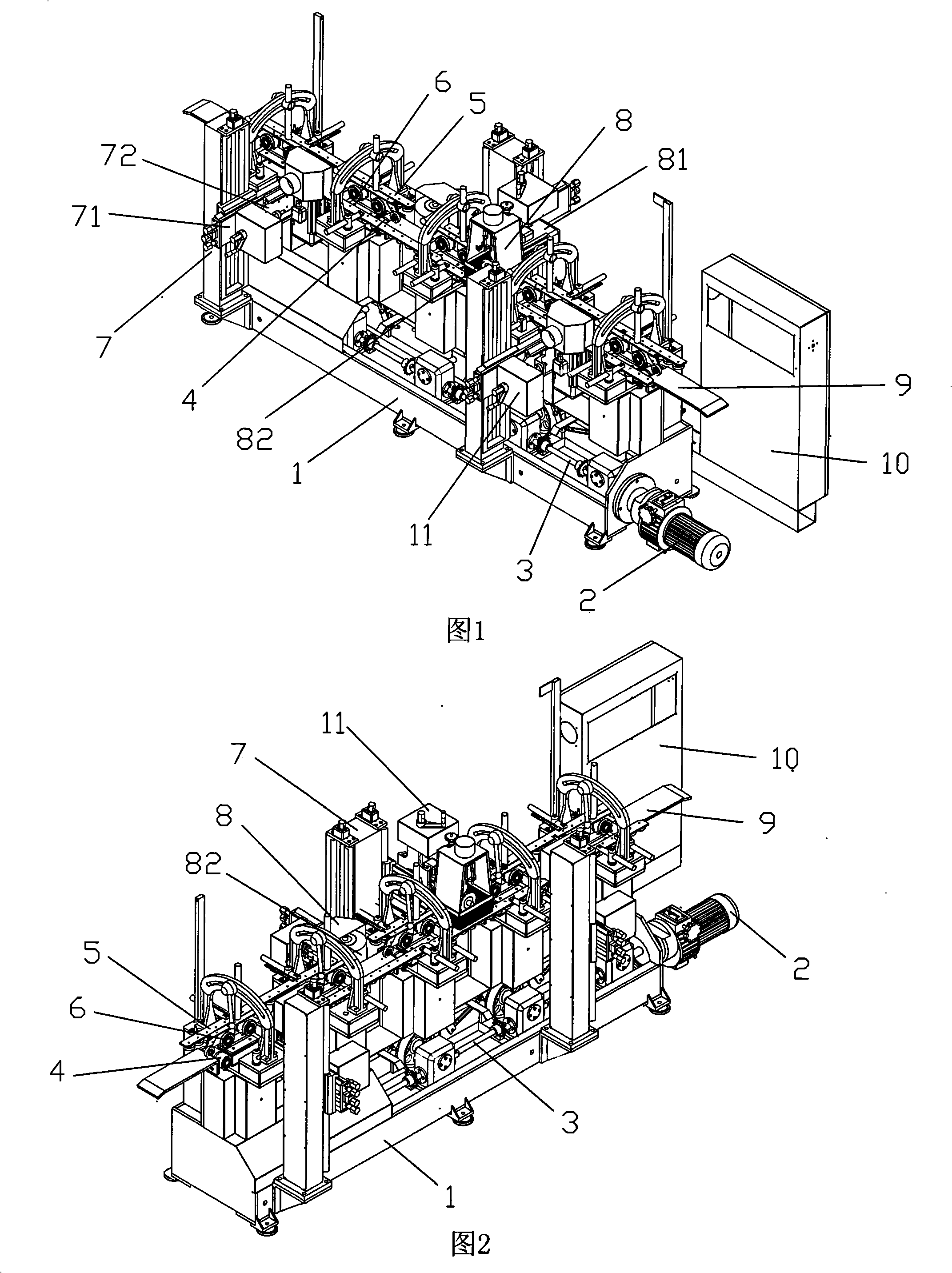

[0012] Referring to Fig. 1 and Fig. 2, a special-shaped wood wire sander includes a machine base 1, and the lower end of the machine base 1 is provided with a worm gear shaft 3 driven by a motor 2, and the pulley on the worm gear shaft 3 is respectively connected to the workbench 9 The drive wheels 4 at the bottom are connected to each other, the base 1 is provided with a press frame 5, the press frame 5 is provided with a driven wheel 6 corresponding to the drive wheel 4, and the base 1 is provided with a vertical slide rail 7, The vertical slide rail 7 is provided with a horizontal slide rail 71, the horizontal slide rail 71 is connected with the compensation slide rail 72 through a turntable, and the compensation slide rail 72 is provided with a grinding device 8, and the grinding device 8 includes a motor base, a motor base A grinding wheel 82 driven by a motor 81 is arranged on the top, and the grinding surface of the grinding wheel 82 matches the shape of the grinding sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com