Track profiling grinding method

A track and profiling technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of weak uniformity of guide rail to wave wear, failure to standardize the grinding surface, and defects in rail surface profiling technology, etc. Achieve the effect of good profiling grinding effect, light weight and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

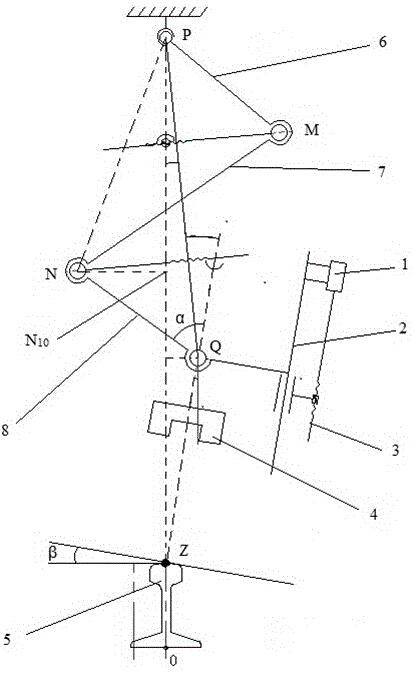

[0030] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Step 1. Place the track profiling grinder at the initial position, take the track cross section where the grinding head 4 rotation axis of the grinder is located as the reference plane, establish a rectangular coordinate system, and measure the coordinate parameters of the track profile. In this embodiment, take The center point of the bottom surface of the track is the origin, and an x0y rectangular coordinate system is established.

[0032] Step 2. Measure and obtain the initial position parameters of the track profiling grinder; note that the fixed center point of the grinder is point P, and the coordinate parameters of the track profiling grinder also include the coordinates of point P. Set point P directly above the center position of the rail, then The coordinates of point P are (0, Yp).

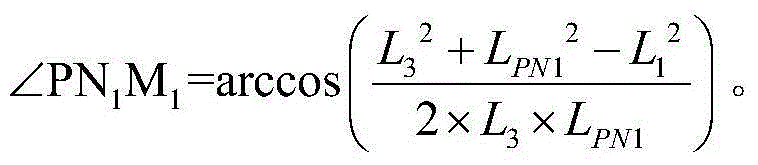

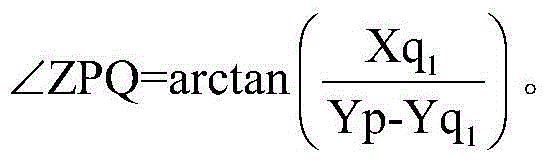

[0033] Step 3. Measure the coordinate parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com