Rail grinding machine

A grinding machine and track technology, applied in track, track laying, track maintenance, etc., can solve the problems of weak uniformity of guide rail to wave wear, unstandardized grinding surface, and no profiling grinding, etc., to achieve Good grinding effect, good flatness and enhanced repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

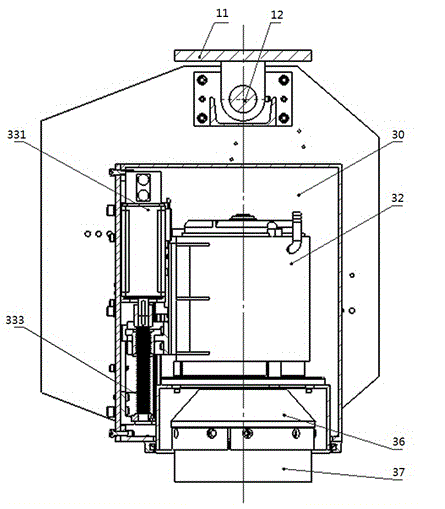

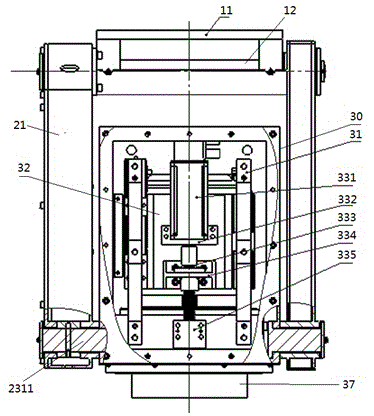

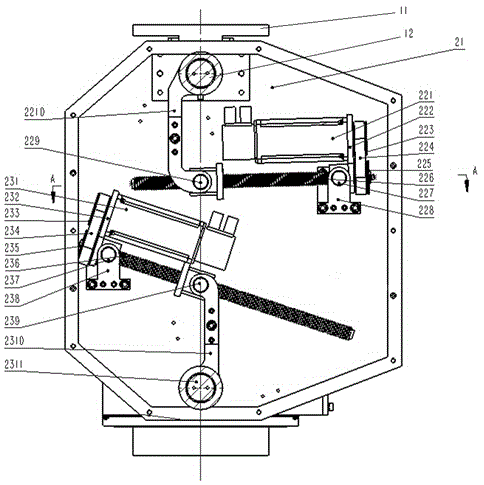

[0034] As shown in the figure, the orbital grinding machine of this embodiment includes a fixed base 11, a grinding motor 32 and a grinding head, the grinding head is specifically a grinding wheel 37, and also includes a horizontal drive unit, a grinding head swing drive unit, a frame and a grinding head. to the drive unit.

[0035] The feed drive unit can drive the grinding motor 32 to move along the axis of the motor, so as to realize pressing or leaving the track to be ground. The feed drive unit in this embodiment has a specific structure such as figure 2 As shown, it includes a feed drive box 30 , a linear guide rail 31 , a feed servo motor 331 , a thrust screw fixing frame, a ball screw 333 , a lead screw nut and a nut fixing frame 334 . The thrust screw fixed mount comprises an upper thrust screw fixed mount 332 and a lower thrust screw fixed mount 335 for installing a ball screw 333; the grinding motor 32 is installed on the linear guide rail 31 and can slide along t...

Embodiment 2

[0043] As an alternative technical scheme of embodiment 1, the structure of grinding motor 32 and grinding head 37, grinding head swing drive unit and feed drive unit are the same as in embodiment 1, but the difference lies in the horizontal drive unit; Displacement, example 2 is to realize horizontal displacement by linear motion. The specific structure of the horizontal drive unit is as follows: Figure 4 As shown, it includes two horizontally moving guide rails 41, which are distributed on the left and right sides below the fixed base 11, and the boom fixing box 21 is hoisted on the two horizontally moving guide rails 41, so that the structure is more stable. Also comprise horizontal motion servo motor 42, two horizontal ball screws 43, two horizontal screw nuts 44, also comprise horizontal driving pulley 45, two horizontal small pulleys 46, two horizontal large pulleys 47, horizontal synchronous Belt 48, horizontal motion servo motor 42 and horizontal driving pulley 45 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com