Gantry edging mechanism and automatic polisher using same

An edge grinding mechanism and gantry technology, which is applied to machine tools, grinders, grinding workpiece supports and other directions suitable for grinding workpiece edges, can solve the problem of dust pollution of the air and the health of operators, low product production efficiency and poor grinding effect. and other problems, to achieve the effect of reducing health hazards, good grinding effect and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

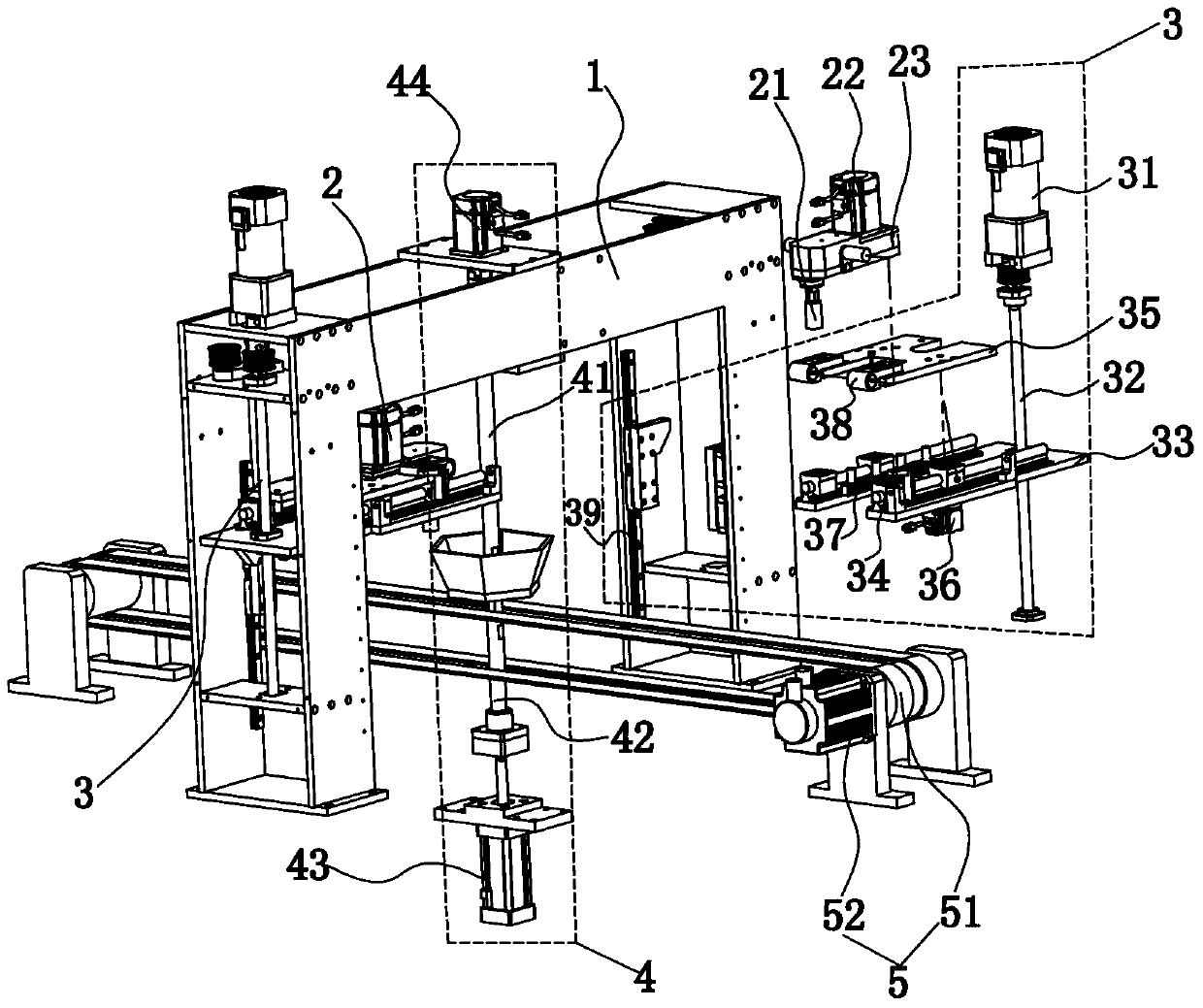

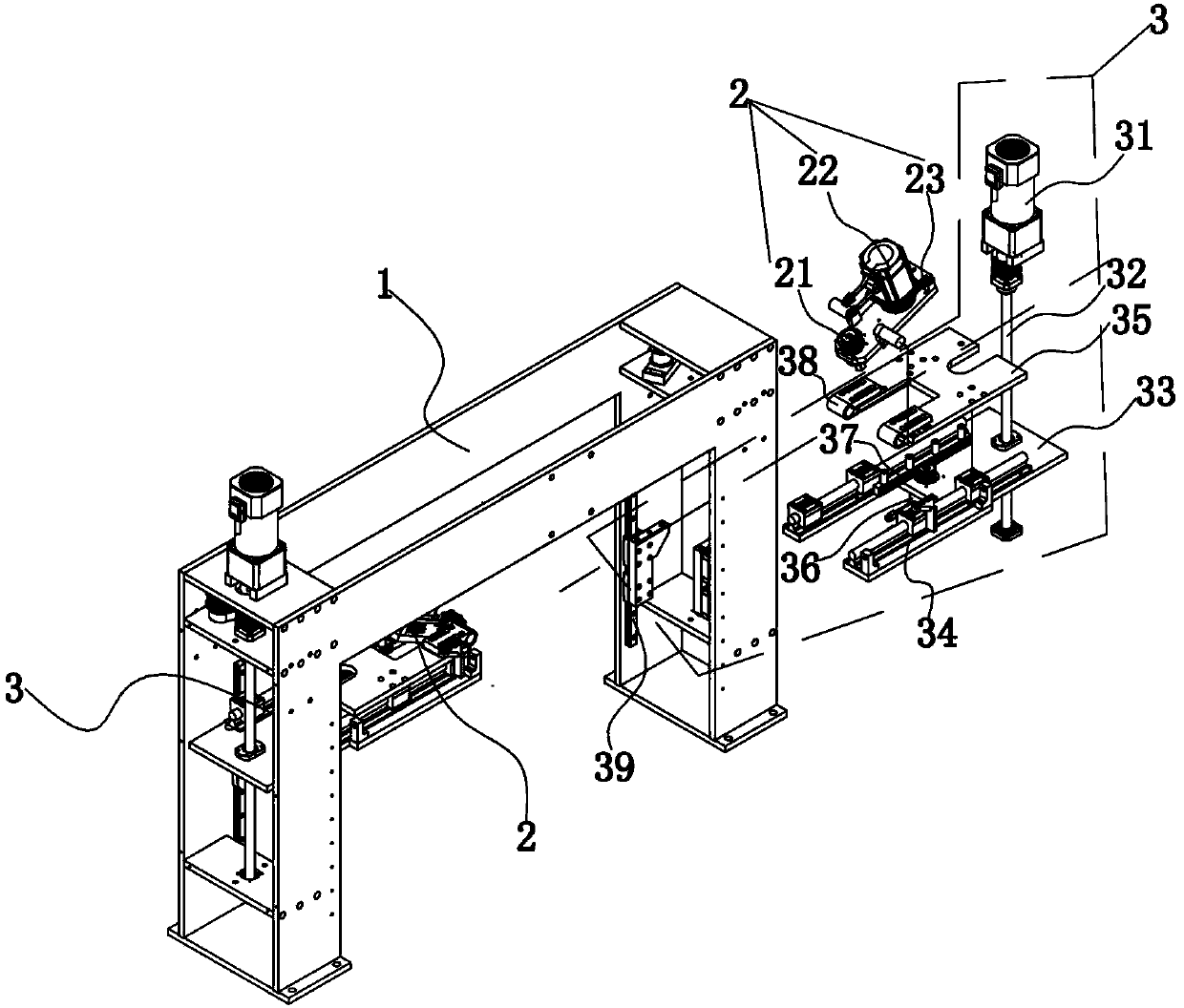

[0020] figure 1 with figure 2 A gantry edging mechanism and an automatic grinding machine using it are schematically shown according to an embodiment of the present invention.

[0021] Such as figure 1 As shown, a gantry edging mechanism includes a gantry frame 1, a grinding assembly 2 and a driving assembly 3; Two, the two side frames of the gantry frame 1 are provided with a grinding assembly 2 and a driving assembly 3; the grinding assembly 2 is driven by the driving assembly 3 to move up and down and back and forth for edging.

[0022] Grinding assembly 2 comprises grinding head 21, grinding motor 22 and grinding frame 23; Downward, the grinding head 21 drives the edge grinding through the grinding motor 22 .

[0023] The drive assembly 3 includes a lifting and rotating motor 31 , a screw mandrel 32 , a lifting frame 33 , a translation slide rail 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com