a grinder

A technology of grinding machine and grinding mechanism, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of dust pollution in the air, the health of operators, and low production efficiency, so as to reduce the Health hazards, increased production efficiency, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

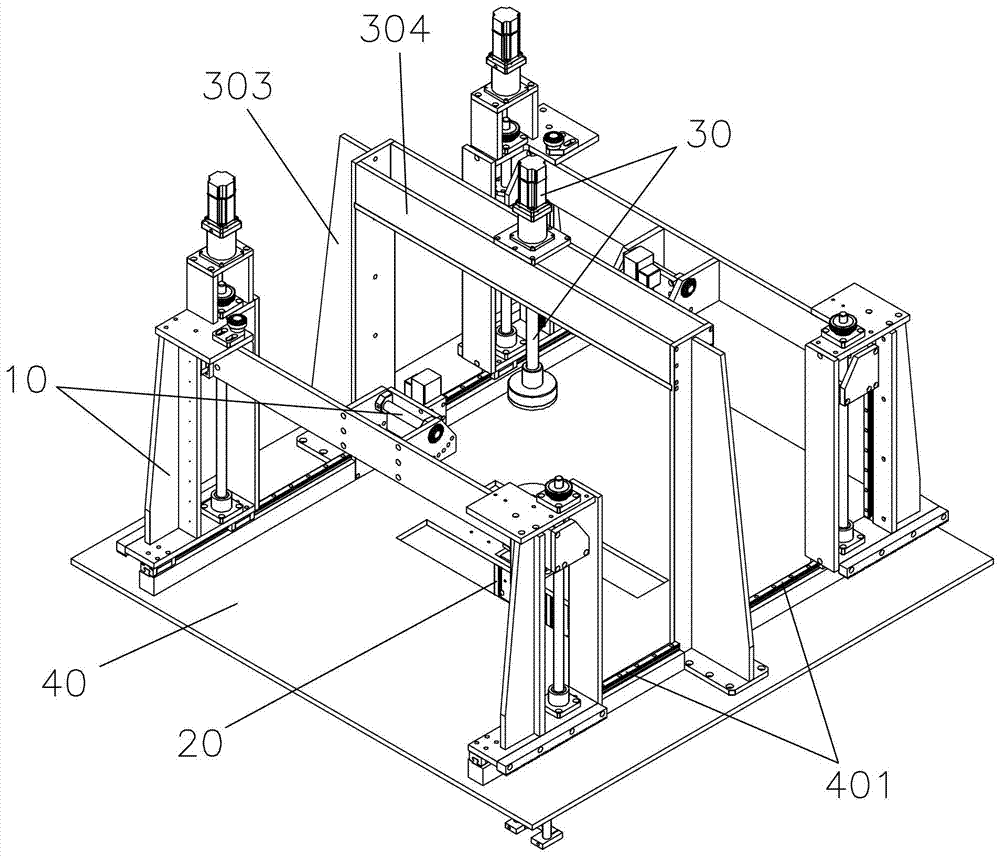

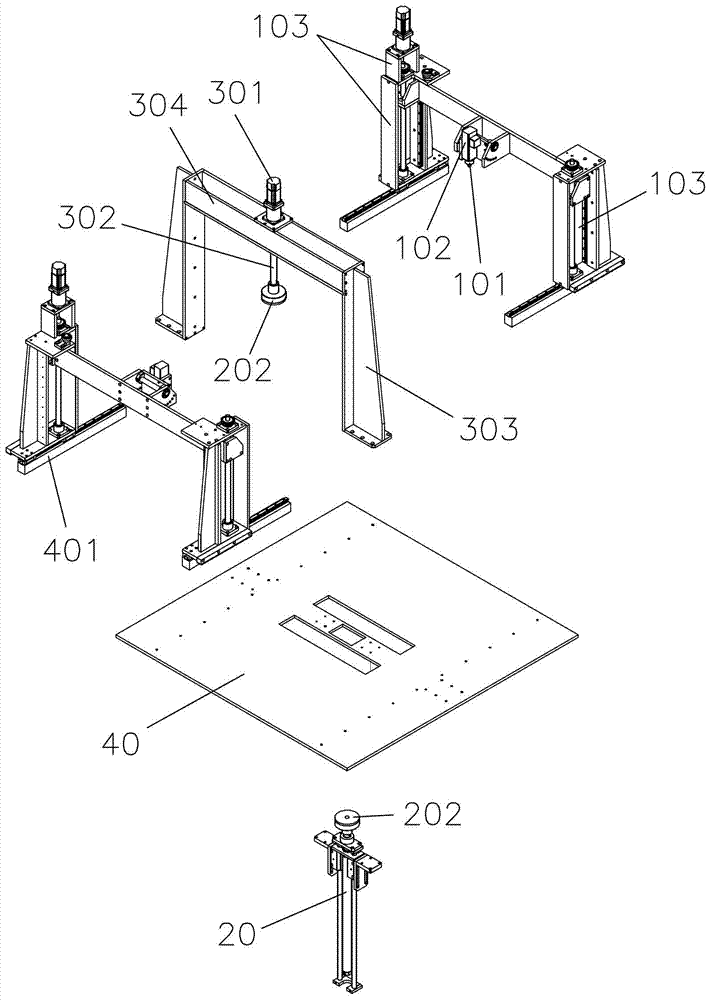

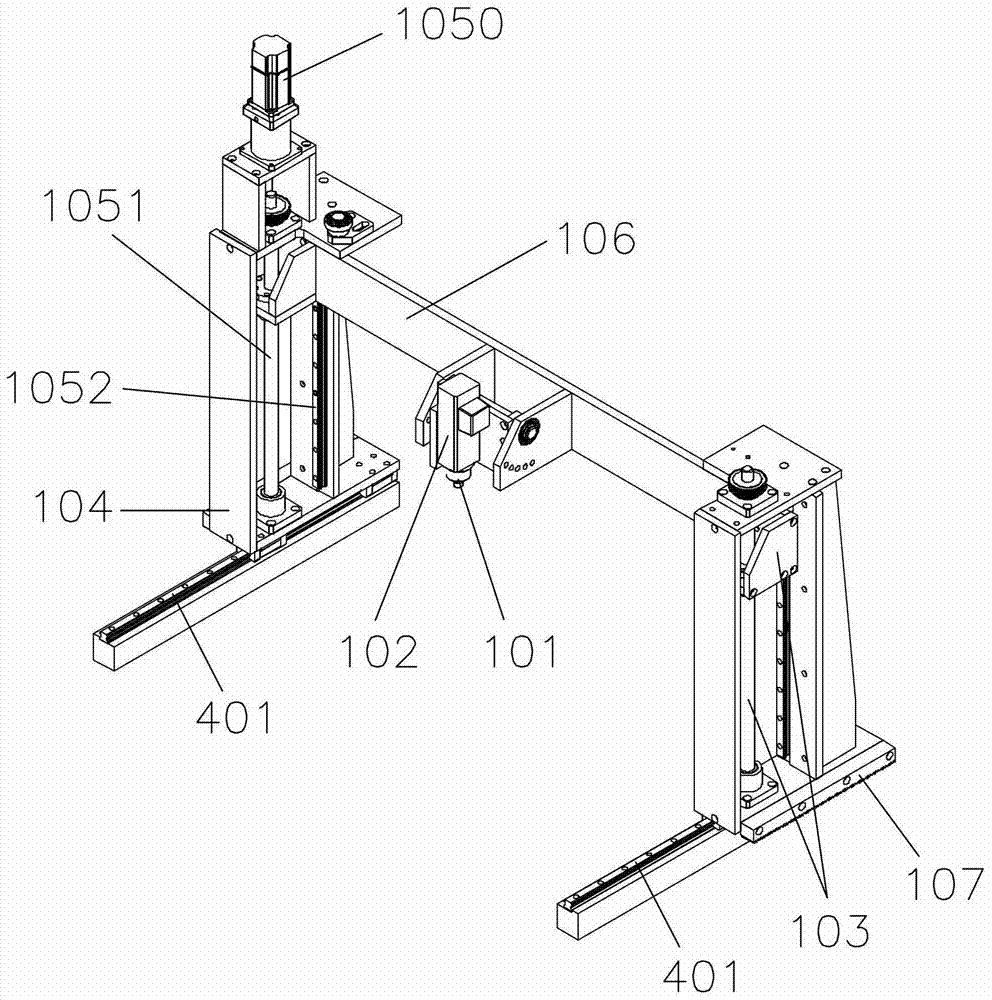

[0022] refer to figure 1 , figure 2 As shown, the present invention discloses a grinding machine, which includes a grinding mechanism 10. The grinding mechanism 10 is composed of a grinding head 101, a grinding head motor 102 and a grinding head driving device 103. The grinding head driving device 103 can make the grinding head 101 Up and down, left and right movement, in addition, this grinding machine also comprises a clamping mechanism 20 and a rotating mechanism 30, and rotating mechanism 30 comprises a rotating motor 301 and an extension shaft 302 fixed on the output shaft of rotating motor 301, and rotating motor 301 is fixed On a rotating mechanism fixing base 303, refer to figure 1 , figure 2 The rotating mechanism fixing base 303 is in the shape of a gantry, and the two ends of the rotating mechanism fixing base 303 are fixedly mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com