Handheld laser welding device

A laser welding and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not having the function of waste collection, easy to splash residue, and inconvenient adjustment of the handheld position, so as to increase practicability and good Anti-splash work and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

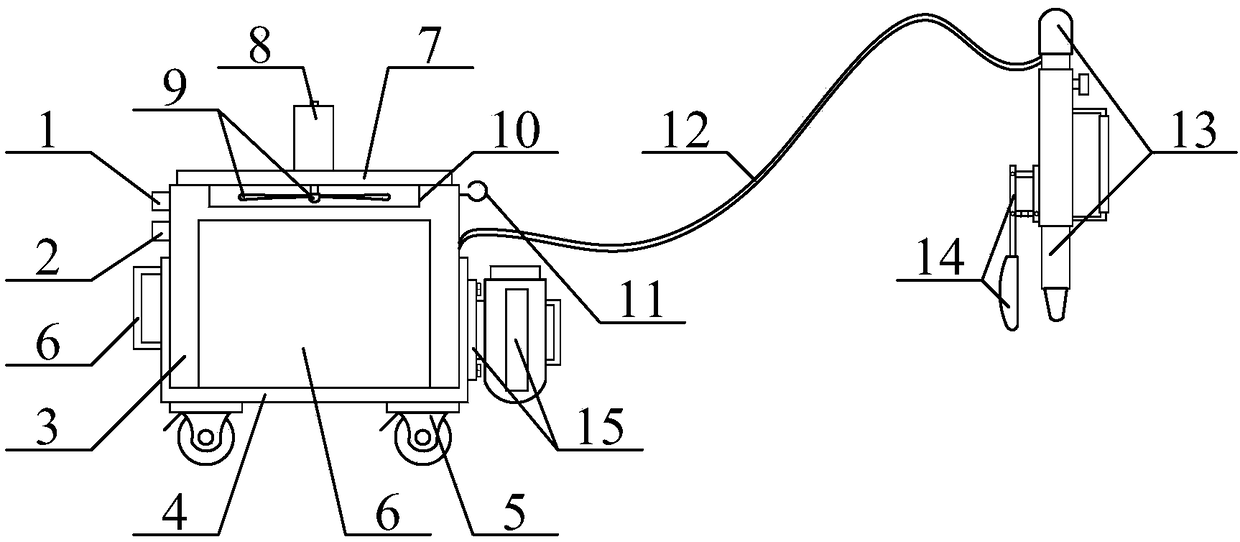

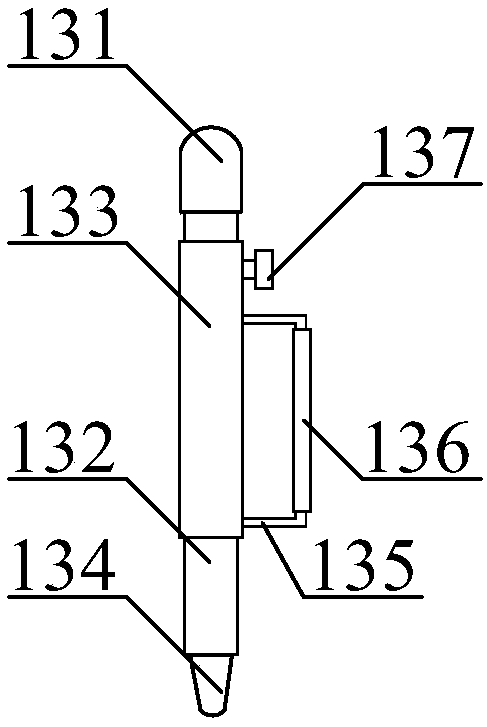

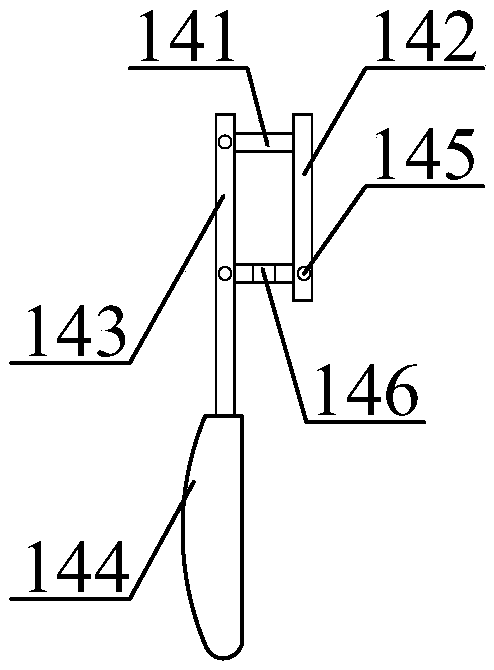

[0038] Such as figure 1 with figure 2As shown, a hand-held laser welding device according to the present invention includes a welding machine switch 1, a heat dissipation switch 2, a welding cabinet 3, a U-shaped moving seat 4, a universal wheel 5 with brake pads, a welding machine 6, and a cabinet cover 7 , heat dissipation motor 8, fan blade 9, hollow cover 10, pull hook 11, optical fiber 12, adjustable hand-held welding torch structure 13, adjustable anti-splash shield structure 14 and absorbable waste debris temporary collection and placement bucket structure 15, so The welding machine switch 1 and the heat dissipation switch 2 are screwed in parallel on the upper left side of the welding cabinet 3 from top to bottom; the welding cabinet 3 bolts are installed on the inner bottom of the U-shaped mobile seat 4; The wheels 5 are bolted to the four corners of the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com