Tungsten inert gas (TIG) welding device and method applicable to narrow-gap groove

A welding device and narrow gap technology, applied in the direction of welding equipment, electrode support device, welding rod characteristics, etc., can solve the problems of poor welding quality, difficult position, posture, etc., achieve low manufacturing cost, convenient welding work, and good welding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

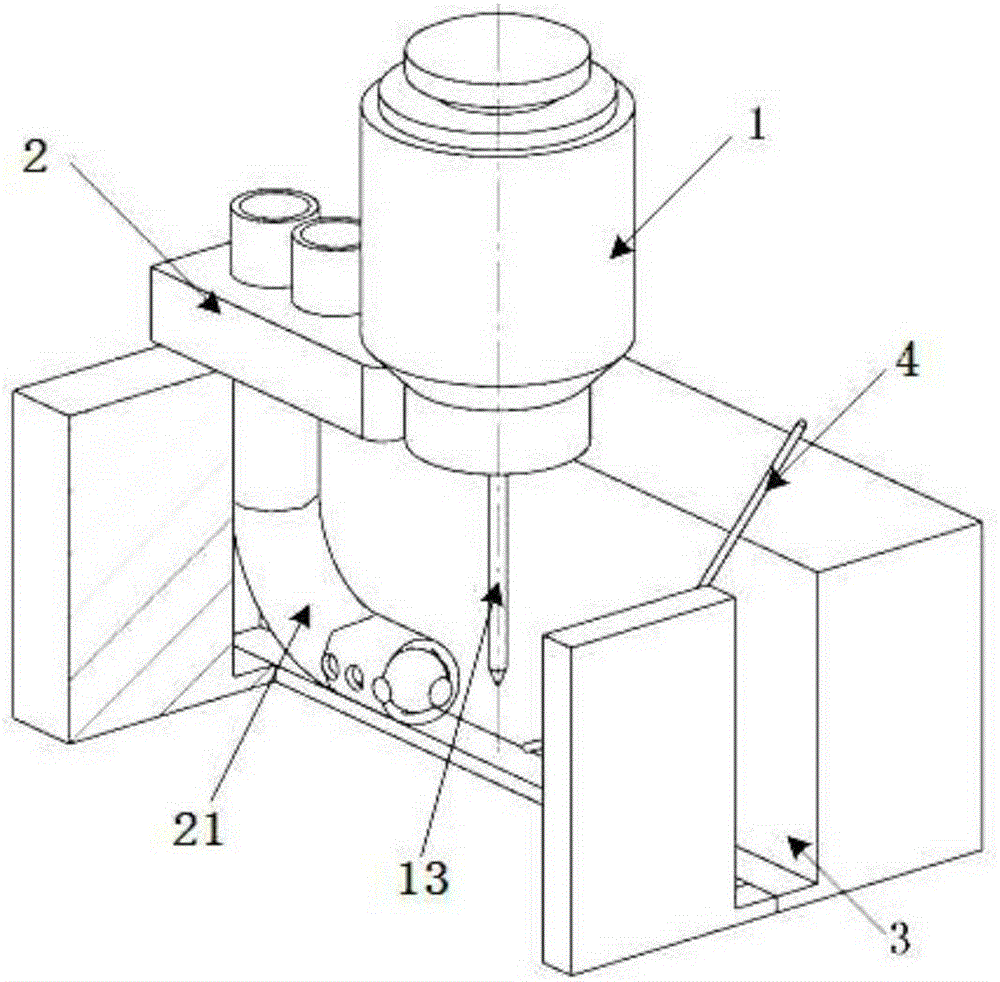

[0047] A TIG welding device suitable for narrow gap grooves, the arrangement of each structure of the device is as follows figure 1 As shown, the groove structure of the workpiece before welding is a narrow gap groove 3, and the groove is narrow and deep. The gun body 11 in the welding torch 1 is located above the groove, and the thin and long tungsten electrode 13 extends into the groove, 5-10 mm away from the bottom surface of the groove, and in front of the welding torch 1 is an automatic wire feeding device. The welding torch 1 moves and continuously supplies the welding wire 4 . The rear side of the welding torch 1 is a protection unit 2, which includes a gas injection copper tube 21 inserted into the groove and following the tungsten electrode 13, and a welding support cover 22 floating above the groove and following the gun body 1.

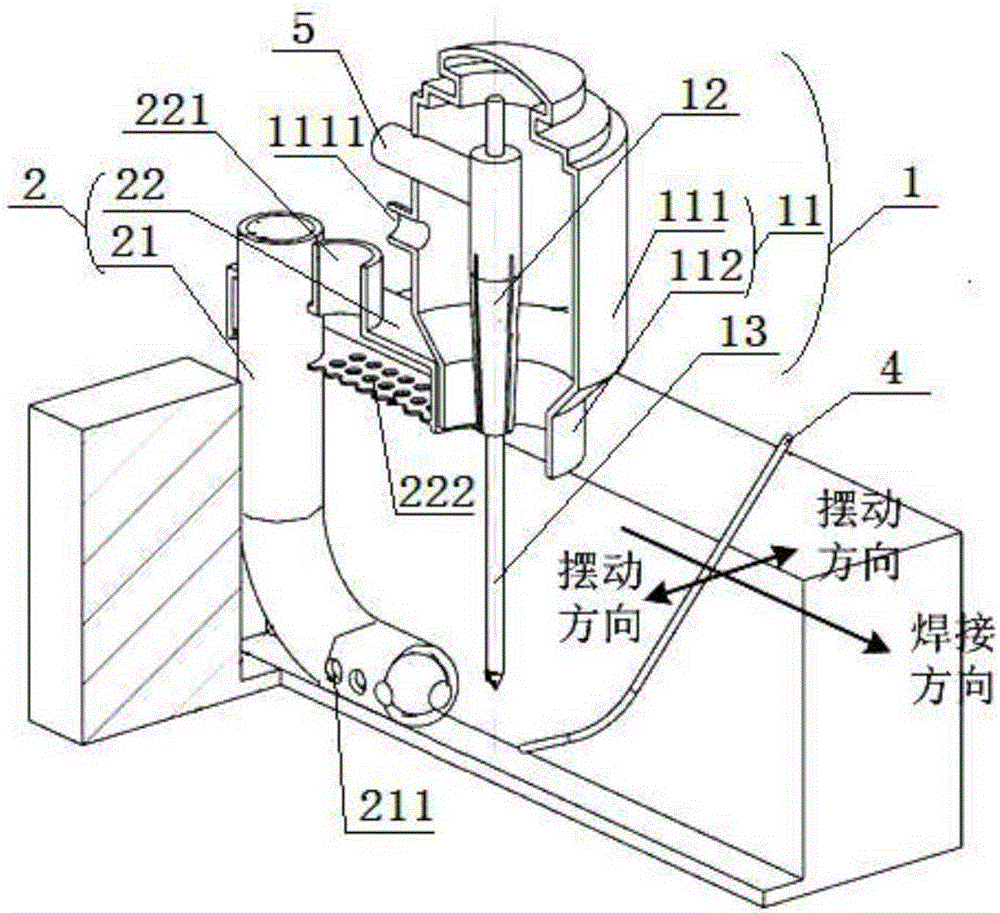

[0048] Such as figure 2 As shown in the cutaway view of the partial structure, before the welding starts, the cable 5 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com