Welding clamp of steel cylinder base

A technology for welding fixtures and steel cylinders, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of steel cylinder clamping that cannot meet different specifications, single fixture, limited use range, etc., and achieve simple structure , Convenient welding work, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

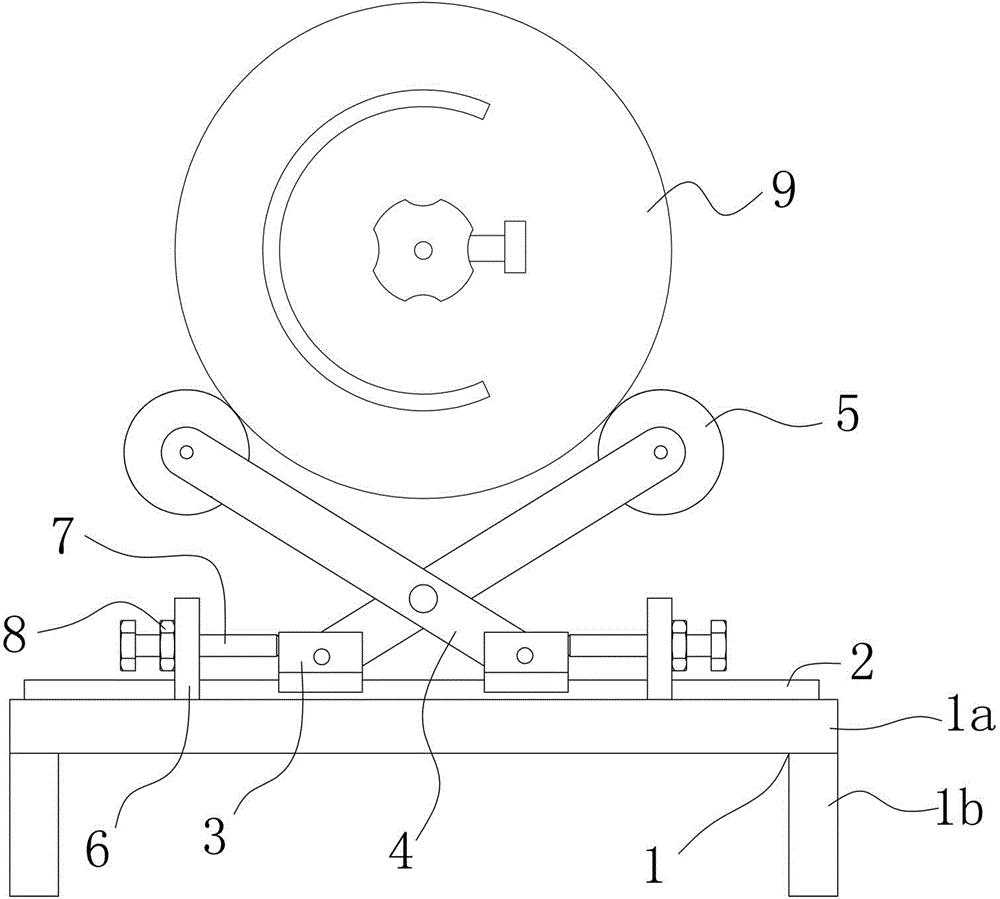

[0012] Such as figure 1 As shown, a welding jig for a steel cylinder base according to an embodiment of the present invention includes a frame 1 and multiple sets of clamp assemblies with the same structure. Multiple sets of clamp assemblies are arranged in parallel and evenly along the width direction of the frame 1. Each set The fixture assembly includes a linear guide rail 2, two sliders 3 matched with the linear guide rail 2, two support rods 4 and two rollers 5, the linear guide rail 2 extends along the length direction of the frame 1, and the two support rods 4 intersect each other and intersect One end of the two support rods 4 is respectively hinged with the corresponding slider 3, and the two supporting rollers 5 are respectively movably installed on the other end of the two support rods 4, and are installed on the frame 1 corresponding to each slider 3 There is an adjustment assembly, the adjustment assembly includes a fixed seat 6 and an adjustment rod 7, the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com