A fire extinguisher bottle automatic rolling machine

A fire extinguisher and rolling machine technology, which is applied in the field of automatic rolling machine for fire extinguisher bottles, can solve the problems of reducing work efficiency, wasting manpower, and high labor intensity, and achieves the effects of reducing work efficiency, improving work efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

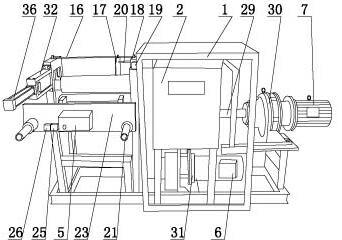

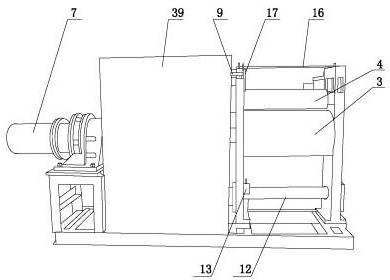

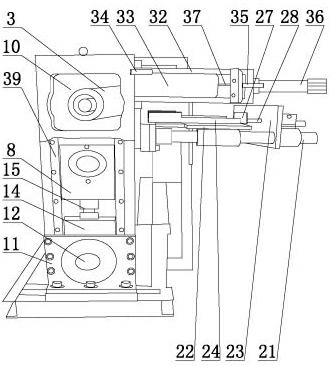

[0016] This fire extinguisher bottle body automatic rolling machine is made of frame 1, electric control box 2, drive roller 3, driven roller 4, feed cylinder 5, material return cylinder 18, transmission motor A6, transmission motor B7. The middle part of the frame 1 is provided with an electric control box 2, and the rear end of the electric control box 2 is provided with a frame backboard 39, and the bottom and one side of the electric control box 2 are respectively installed with a transmission motor A6 and a transmission motor B7 through the frame 1, On the other side frame 1 of the electric control box 2, the driving roller 3 is installed through the slide rail 38 and the main slider 8, and the driven roller 4 is installed on the top of the driving roller 3 through the frame 1, and the driven roller The frame 1 at one end of 4 is provided with a proximity switch A9, and the frame 1 at the other end of the driven roller 4 is provided with an ejection port 10.

[0017] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com