Grinding device for rim of red wine glass

A red wine glass and grinding disc technology, which is applied to the grinding drive device, grinder, grinding workpiece support and other directions, can solve the problems of red wine glass vibration and high consumption, and achieve the effect of saving manpower and labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

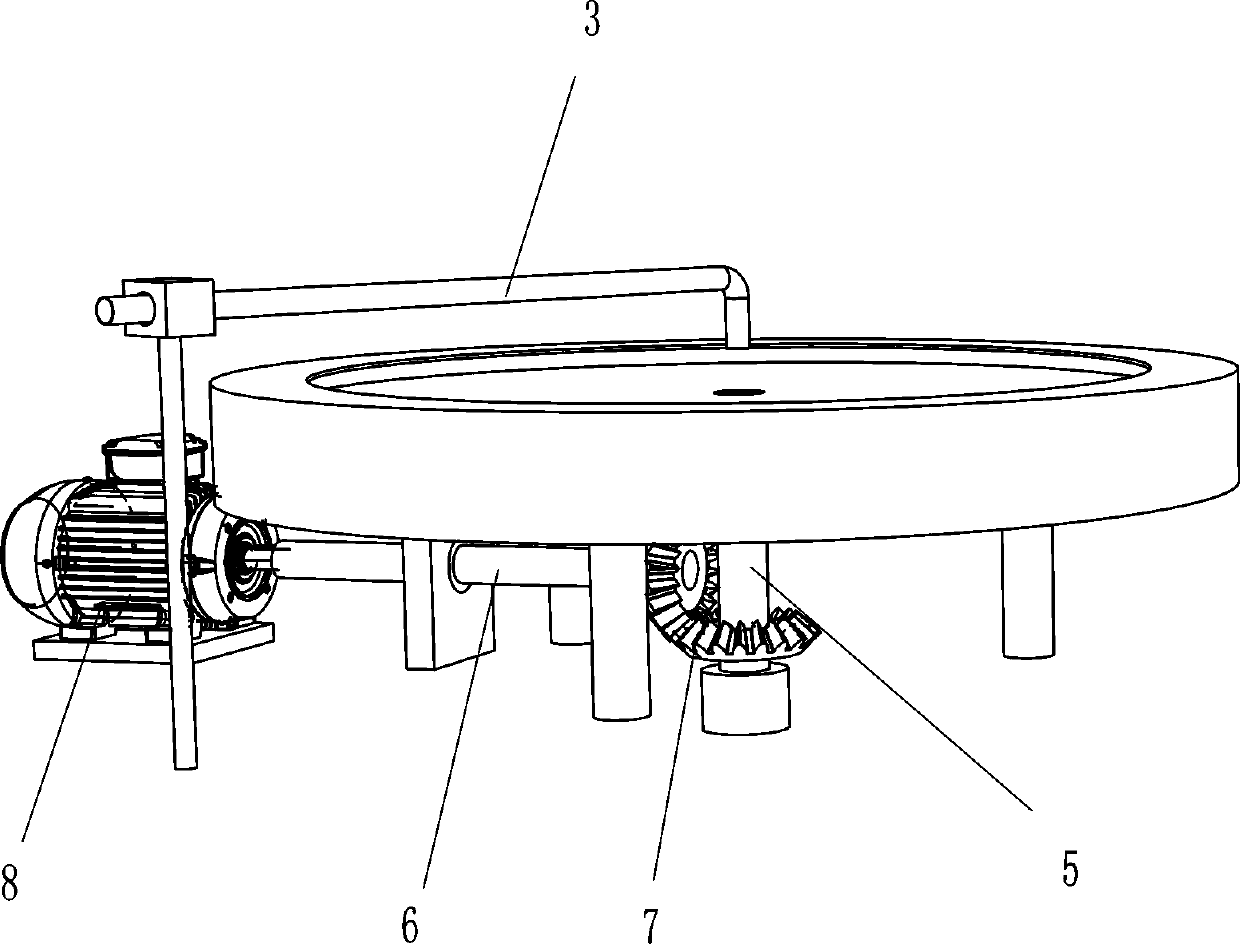

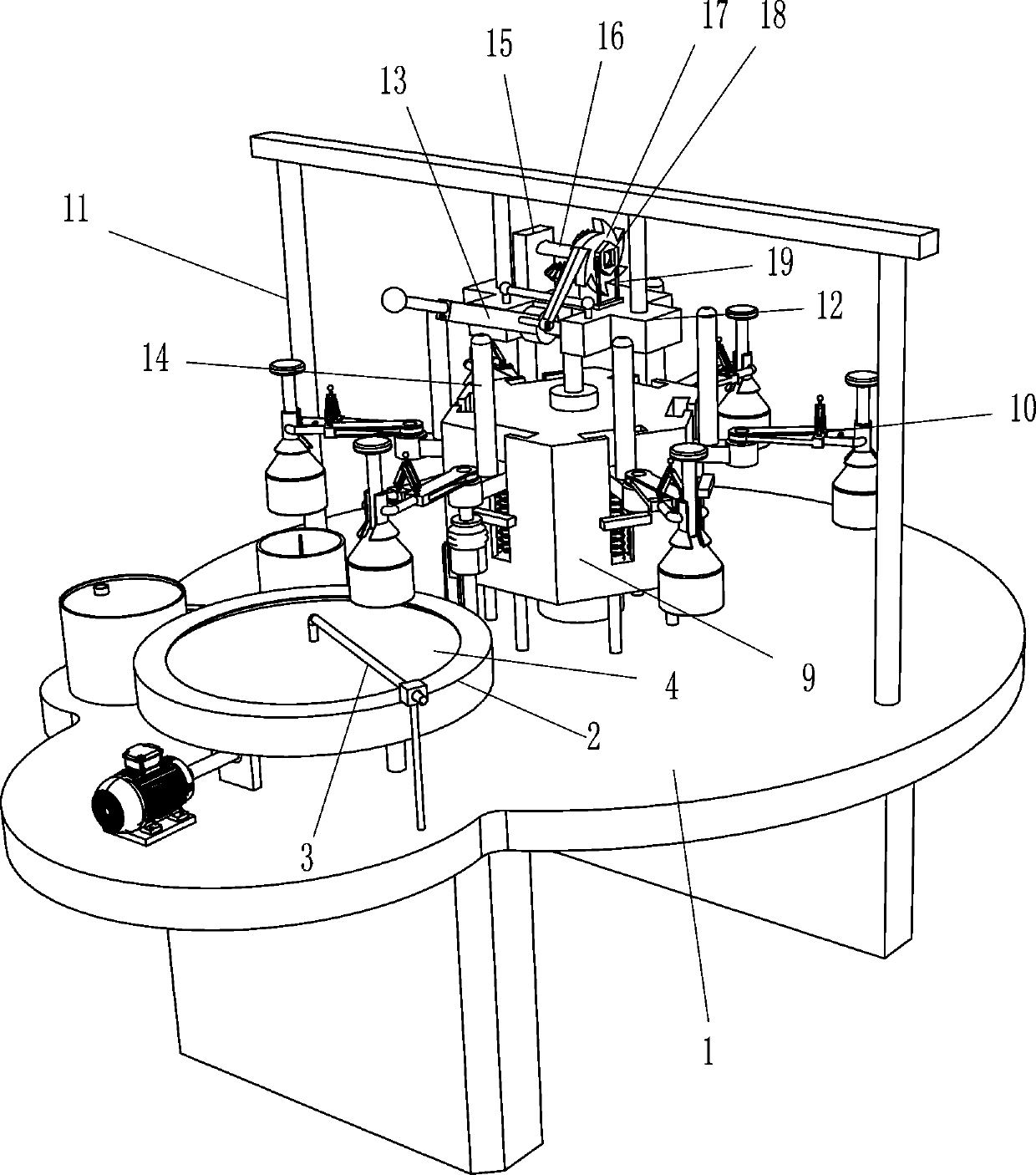

[0026] A kind of red wine glass rim grinding device, such as Figure 1-4 As shown, it includes a workbench 1, a cylindrical tank body 2, a drip pipe 3, a grinding disc 4, a first rotating shaft 5, a second rotating shaft 6, a first bevel gear 7 and a servo motor 8, and the front side of the top of the workbench 1 is connected with a cylindrical Tank body 2, the top of the workbench 1 on the right side of the cylindrical tank body 2 is connected with a drip pipe 3, and the cylindrical tank body 2 is connected with a millstone 4 in a rotating manner, the water outlet end of the drip tube 3 is aligned with the millstone 4, and the bottom of the millstone 4 is rotated in the middle A first rotating shaft 5 is connected, and the first rotating shaft 5 is rotatably matched with the workbench 1. The front side of the top of the workbench 1 is rotatably connected with a second rotating shaft 6, and the second rotating shaft 6 and the first rotating shaft 5 are connected with a first co...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a third bearing seat 15, a third rotating shaft 16, a hexagonal ratchet 17, a hexagonal block 18, an elastic piece 19, a pawl 20, a third rotating shaft 21 and a second bevel gear 22, and the top of the mounting plate 12 The left side is connected with a third bearing seat 15, the third bearing seat 15 is rotatably connected with a third rotating shaft 16, the third rotating shaft 16 is connected with a hexagonal ratchet 17, and the right side of the hexagonal ratchet 17 is connected with a hexagonal block 18, The top of the workbench 1 on the front and rear sides of the hexagonal block 18 is connected with elastic sheets 19, and the elastic sheets 19 on both sides clamp the two sides of the hexagonal block 18 respectively. The ratchet 17 cooperates, and the middle part of the mounting plate 12 is rotatably connected with a third rotating shaft 21, the third rotating shaft 21 is connec...

Embodiment 3

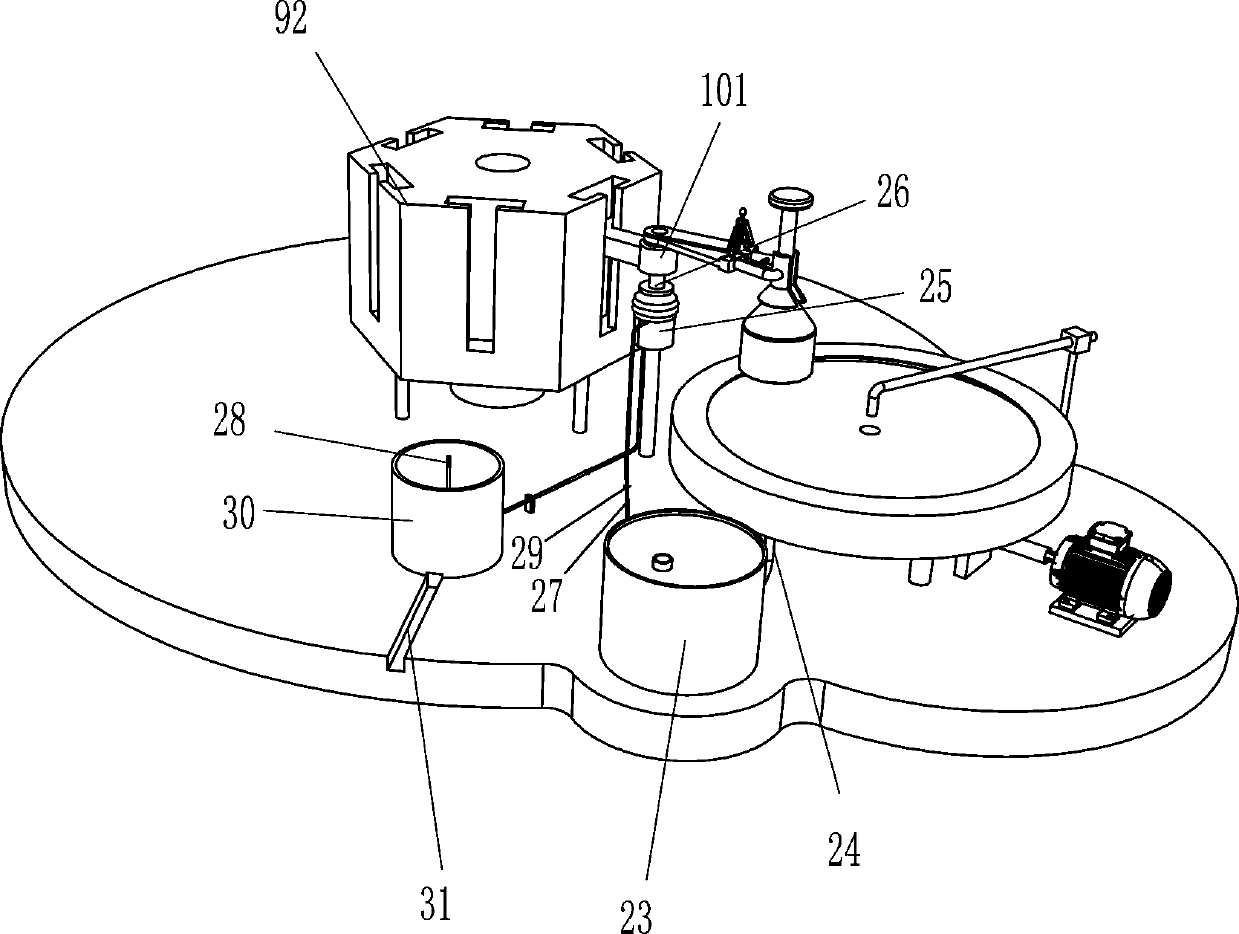

[0034] On the basis of Example 2, such as Figure 6 As shown, it also includes a water collection tank 23, a connecting pipe 24, a compressible container 25, an extrusion plate 26, a water suction pipe 27, a water spray pipe 28, a one-way valve 29 and a cylindrical container 30, and the left side of the front side of the top of the workbench 1 A water collection tank 23 is connected to the top of the water collection tank 23, a connecting pipe 24 is connected between the liquid inlet end of the water collection tank 23 and the liquid outlet end of the cylindrical tank body 2, and the top of the workbench 1 between the hexagonal mounting block 92 and the cylindrical tank body 2 is connected. There is a compressible container 25, and a squeeze plate 26 is connected to the bottom of the second bearing seat 101. The squeeze plate 26 will move to the top of the compressible container 25, and the liquid inlet end of the compressible container 25 and the liquid outlet end of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com