Triangular prism chamfering and grinding equipment for toy building blocks

A technology for triangular prisms and building blocks, which is applied to the field of triangular prism chamfering grinding equipment for toy building blocks, can solve the problems of cutting hands by grinding equipment, labor consumption, danger, etc., and achieves the effects of saving manpower, simple operation and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] first implementation

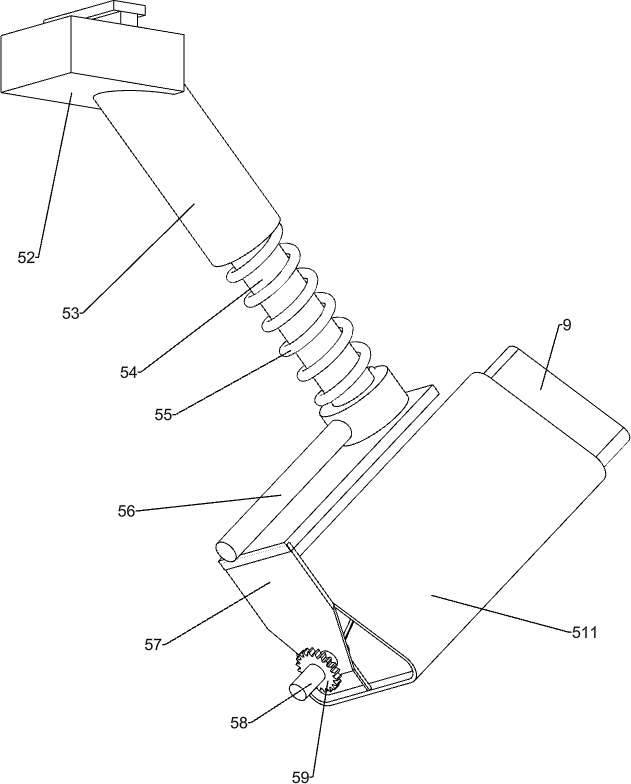

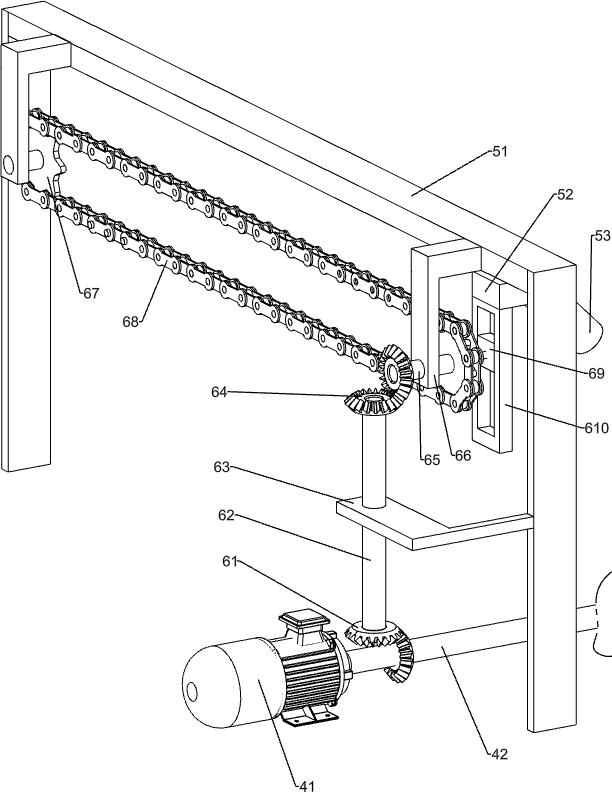

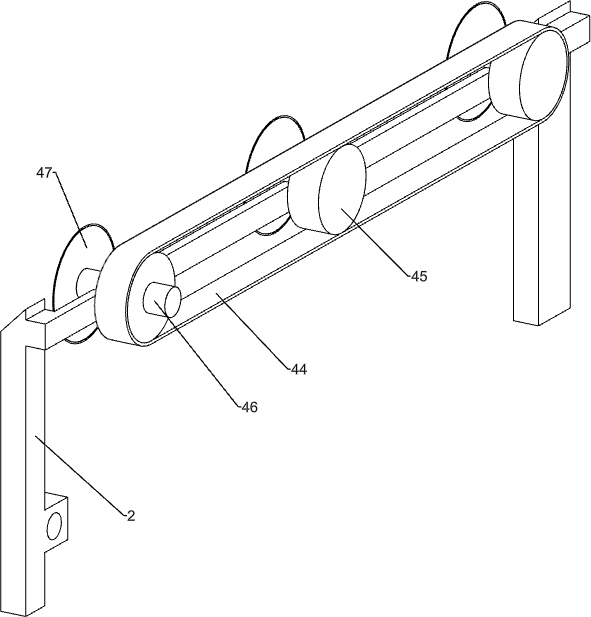

[0031] A toy building block triangular prism chamfering grinding equipment, such as Figure 1-7 As shown, it includes a base plate 1, a support frame 2 and a cutting frame 3. The support frame 2 is connected to the top right side of the base plate 1, and the cutting frame 3 is connected to the support frame 2. It also includes a grinding assembly 4 and an autorotation assembly 5. The base plate 1 A grinding assembly 4 is provided between the support frame 2 and an autorotation assembly 5 is provided between the bottom plate 1 and the cutting frame 3 .

[0032] Grinding assembly 4 comprises motor 41, rotating shaft 42, drive belt 43, rack belt 44, driving gear 45, driving bar 46, polishing disc 47 and pinch wheel 48, and base plate 1 top left front portion is equipped with motor 41, and motor 41 The output shaft is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com